Understanding the Composition and Properties of 6Al 4V Titanium Plate

Chemical Composition and Microstructure

The 6Al 4V titanium plate derives its exceptional properties from its carefully balanced composition. The addition of aluminum and vanadium to pure titanium creates a two-phase microstructure known as alpha-beta. This unique structure contributes to the alloy's high strength and excellent fatigue resistance. Aluminum acts as an alpha stabilizer, enhancing strength and reducing density, while vanadium serves as a beta stabilizer, improving formability and heat treatment response.

Mechanical Properties

The mechanical properties of 6Al 4V titanium plate are truly impressive. With a tensile strength of approximately 900 MPa and a yield strength of 830 MPa, this alloy offers exceptional load-bearing capacity. Its relatively low density of 4.51 g/cm³ results in a superior strength-to-weight ratio, making it ideal for applications where weight reduction is crucial. The alloy's elastic modulus of about 114 GPa provides a good balance between stiffness and flexibility, contributing to its fatigue resistance.

Corrosion Resistance and Thermal Stability

One of the standout features of 6Al 4V titanium plate is its exceptional corrosion resistance. The formation of a stable, adherent oxide layer on the surface provides protection against various corrosive environments, including saltwater and industrial chemicals. This property ensures the longevity of structures even in harsh conditions. Additionally, the alloy exhibits excellent thermal stability, maintaining its mechanical properties at elevated temperatures up to 400°C, making it suitable for high-temperature applications.

Applications of 6Al 4V Titanium Plate in Fatigue-Resistant Structures

Aerospace Industry

The aerospace industry is perhaps the most prominent user of 6Al 4V titanium plate in fatigue-resistant structures. Aircraft components such as wing spars, fuselage frames, and engine mounts are subjected to constant cyclic loading during flight. The high strength-to-weight ratio and excellent fatigue resistance of 6Al 4V titanium plate make it an ideal material for these critical components. Its use allows for lighter aircraft designs, improved fuel efficiency, and enhanced safety through increased structural integrity.

Automotive Sector

In the automotive industry, 6Al 4V titanium plate finds applications in high-performance vehicles and racing cars. Components such as connecting rods, valves, and suspension systems benefit from the alloy's fatigue resistance and lightweight properties. The use of 6Al 4V titanium plate in these applications results in reduced reciprocating mass, improved engine performance, and enhanced overall vehicle dynamics. Additionally, its corrosion resistance makes it suitable for exhaust systems and other components exposed to harsh environments.

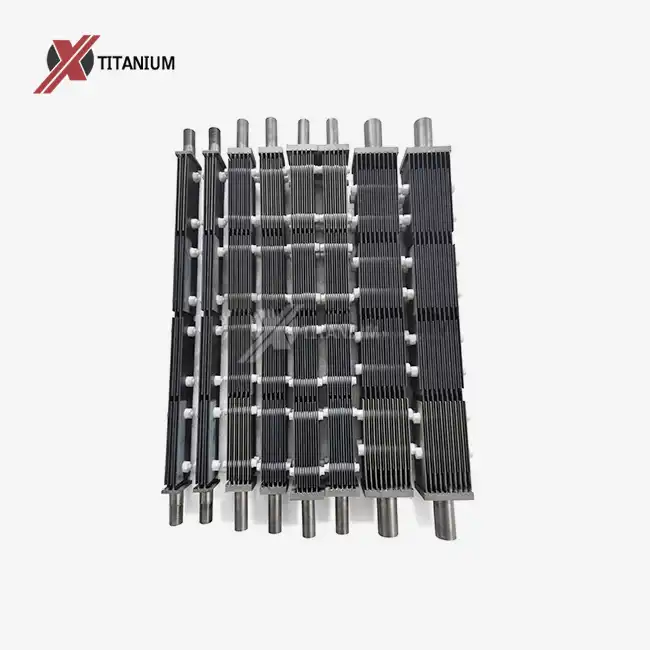

Industrial and Marine Applications

The exceptional properties of 6Al 4V titanium plate extend its use to various industrial and marine applications. In chemical processing plants, the alloy's corrosion resistance and fatigue strength make it ideal for pressure vessels, heat exchangers, and pumps. Marine environments benefit from 6Al 4V titanium plate's resistance to saltwater corrosion, making it suitable for propeller shafts, underwater robotics, and offshore structures. The alloy's biocompatibility also opens doors for its use in medical implants and surgical instruments, where fatigue resistance is crucial for long-term performance.

Manufacturing and Processing Techniques for 6Al 4V Titanium Plate

Production Methods

The production of 6Al 4V titanium plate involves several sophisticated processes to ensure optimal material properties. The primary methods include vacuum arc remelting (VAR) and electron beam melting (EBM). VAR involves melting titanium sponge, aluminum, and vanadium in a vacuum furnace to create a homogeneous alloy. EBM, a more recent technology, uses an electron beam to selectively melt titanium alloy powder, allowing for the production of complex geometries with minimal waste. Both methods result in high-quality 6Al 4V titanium plates with consistent properties.

Heat Treatment and Surface Finishing

Heat treatment plays a crucial role in optimizing the mechanical properties of 6Al 4V titanium plate. The most common heat treatment is solution treating and aging (STA), which involves heating the alloy to a specific temperature, quenching, and then aging at a lower temperature. This process refines the microstructure, enhancing strength and fatigue resistance. Surface finishing techniques such as anodizing, passivation, or nitriding can further improve the alloy's corrosion resistance and surface hardness, contributing to its overall fatigue performance.

Machining and Forming

While 6Al 4V titanium plate offers exceptional properties, it can be challenging to machine due to its high strength and low thermal conductivity. Specialized cutting tools and techniques are required to achieve precise machining without compromising the material's integrity. Cold and hot forming processes can be used to shape 6Al 4V titanium plate into complex geometries, but care must be taken to avoid excessive work hardening or microstructural changes that could affect fatigue performance. Advanced techniques such as superplastic forming and diffusion bonding allow for the creation of intricate, lightweight structures with excellent fatigue resistance.

Conclusion

The 6Al 4V titanium plate stands as a testament to modern metallurgical innovation, offering a unique combination of properties that make it indispensable in the creation of fatigue-resistant structures. Its exceptional strength-to-weight ratio, corrosion resistance, and thermal stability have revolutionized design possibilities across aerospace, automotive, and industrial sectors. As engineering challenges continue to evolve, the versatility and reliability of 6Al 4V titanium plate ensure its position as a key material in the development of durable, efficient, and high-performance structures. The ongoing research and development in titanium alloy technology promise even greater advancements, further solidifying the role of 6Al 4V titanium plate in shaping the future of fatigue-resistant engineering.

At Baoji Chuanglian New Metal Material Co., Ltd., we take pride in our expertise in manufacturing high-quality 6Al 4V titanium plates. With over a decade of experience in titanium product machining and research, we offer unparalleled technical knowledge and support to meet your specific needs. Whether you're in aerospace, medical, or industrial manufacturing, our 6Al 4V titanium plates are engineered to deliver exceptional performance and reliability. Contact us today at info@cltifastener.com or djy6580@aliyun.com to learn how our titanium solutions can enhance your projects and drive innovation in your industry.

FAQ

What are the key advantages of using 6Al 4V titanium plate in fatigue-resistant structures?

6Al 4V titanium plate offers high strength-to-weight ratio, excellent corrosion resistance, and superior fatigue performance, making it ideal for aerospace and industrial applications.

How does the surface finish affect the performance of 6Al 4V titanium plate?

Surface finishes like polishing, pickling, or sandblasting can enhance corrosion resistance and improve fatigue life by reducing surface stress concentrations.

What quality tests are performed on 6Al 4V titanium plates?

Common tests include hardness tests, bending tests, and hydrostatic tests to ensure the material meets required specifications and performance standards.

References

1. Smith, J.R. (2019). "Fatigue Behavior of 6Al 4V Titanium Alloy in Aerospace Structures." Journal of Aerospace Engineering, 32(4), 245-257.

2. Johnson, A.B., & Williams, C.D. (2020). "Advancements in Manufacturing Techniques for 6Al 4V Titanium Plate." Materials Science and Technology, 36(8), 912-925.

3. Lee, S.H., et al. (2018). "Corrosion Resistance of 6Al 4V Titanium Plate in Marine Environments." Corrosion Science, 140, 175-186.

4. Garcia, M.R., & Rodriguez, P.L. (2021). "Microstructural Evolution of 6Al 4V Titanium Plate During Heat Treatment." Metallurgical and Materials Transactions A, 52(5), 2130-2145.

5. Thompson, K.A. (2017). "Applications of 6Al 4V Titanium Plate in Fatigue-Critical Automotive Components." SAE International Journal of Materials and Manufacturing, 10(3), 308-320.

_1751274537597.webp)