- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Are Titanium Flange Bolts the Ultimate Solution for Corrosion Resistance in Harsh Environments?

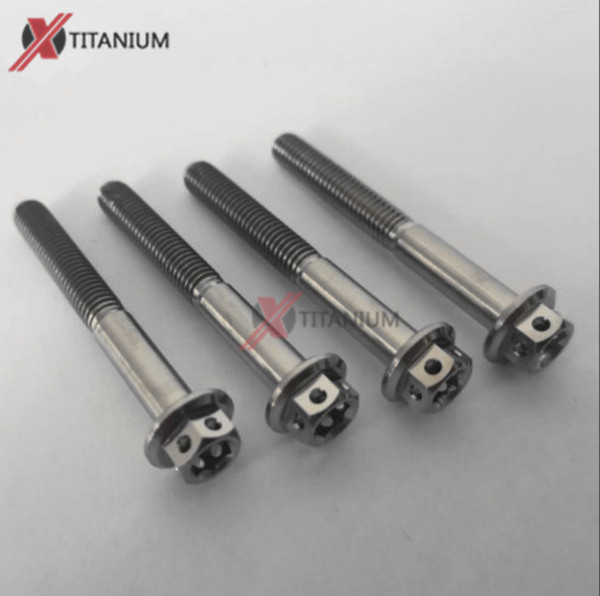

Titanium is renowned for its exceptional strength-to-weight ratio and resistance to corrosion, making it an indispensable material in a variety of industries. One of the most commonly used titanium components is the Titanium Flange Bolt. These bolts offer superior performance in applications where traditional fasteners, such as stainless steel bolts, may not provide the same level of reliability. This blog will delve into the numerous benefits and applications of titanium flange bolts, exploring how they compare to other fasteners, and why they should be your top choice when dealing with harsh or corrosive environments.

What Are Titanium Flange Bolts, and Why Are They Unique?

Titanium flange bolts are fasteners made from titanium alloy, commonly used in environments where strength, weight, and resistance to corrosion are critical. The "flange" part of the name refers to a disc-shaped area at the base of the bolt that helps distribute the load more evenly across the surface. This unique design ensures that the bolt maintains its integrity even under extreme pressure, vibration, and temperature variations.

The titanium material itself is a lightweight yet strong metal, offering corrosion resistance superior to that of stainless steel, especially in challenging environments like marine, chemical, and aerospace industries. Furthermore, titanium’s ability to withstand oxidation and galvanic corrosion makes it an ideal choice for applications in saltwater, acidic, and alkaline environments.

How Do Titanium Flange Bolts Compare to Stainless Steel in Strength and Durability?

When comparing titanium flange bolts to traditional stainless steel fasteners, several factors set titanium apart. Titanium has a higher strength-to-weight ratio than steel, which means it can withstand higher levels of stress without adding excess weight. This makes it particularly valuable in industries where minimizing weight is crucial, such as aerospace, military, and automotive sectors.

Additionally, titanium boasts unparalleled corrosion resistance. Unlike stainless steel, which can degrade over time due to rust or corrosion in certain environments, titanium does not corrode, rust, or stain as easily. Its natural oxide layer helps protect the material from further damage, even in aggressive environments like seawater or high-temperature gases.

Stainless steel bolts, while affordable and strong in many applications, are prone to corrosion when exposed to extreme conditions. This can lead to failure, which is particularly dangerous in critical systems. In contrast, titanium flange bolts maintain their integrity longer, offering a more durable solution for long-term projects or machinery.

What Are the Key Applications of Titanium Flange Bolts in Modern Industries?

Titanium flange bolts are used in a wide array of industries due to their outstanding properties. Here are some of the key sectors where these bolts are most commonly employed:

1. Aerospace Industry

In the aerospace industry, reducing weight without compromising on strength is a major concern. Titanium flange bolts are commonly used in aircraft and spacecraft manufacturing, where their lightweight nature and high strength make them ideal for applications such as engine components, wing structures, and body fittings. The corrosion resistance of titanium also ensures that these bolts perform reliably in the extreme conditions of flight, where both temperature fluctuations and exposure to aggressive substances are common.

2. Marine Industry

The marine environment is known for its high levels of saltwater exposure, which can cause rapid corrosion in many metals. Titanium flange bolts are widely used in the construction of ships, submarines, and offshore platforms because they resist corrosion caused by saltwater. Their durability is crucial in ensuring the long-term functionality of critical systems like hulls, engines, and pipelines.

3. Chemical Processing

In chemical processing plants, where materials are often exposed to acidic or alkaline environments, titanium flange bolts offer excellent resistance to corrosion and wear. These bolts are used to secure pipes, tanks, and reactors in such environments, ensuring a tight seal and preventing leaks that could lead to catastrophic failures or hazardous chemical spills.

4. Automotive Industry

In high-performance vehicles, especially racing cars, reducing weight while maintaining strength is essential. Titanium flange bolts are used in critical parts such as suspension systems, engine components, and exhaust systems, where their strength and corrosion resistance are crucial. The ability of titanium to withstand high temperatures also makes it an ideal choice for engine components exposed to intense heat.

5. Medical Applications

Titanium is biocompatible, meaning it is safe for use in the human body without causing rejection or irritation. Titanium flange bolts are used in various medical devices, such as implants and surgical tools, where the material's corrosion resistance and strength are essential. In addition to durability, titanium’s compatibility with the human body makes it ideal for use in implants such as joint replacements and dental prosthetics.

Why Should You Choose Titanium Flange Bolts Over Traditional Fasteners for Your Projects?

There are several reasons why titanium flange bolts should be your first choice for demanding applications:

1. Superior Corrosion Resistance

Titanium's natural oxide layer provides an effective barrier against corrosion. Unlike steel or aluminum, which can corrode when exposed to certain chemicals, titanium remains intact, even when exposed to seawater or aggressive chemicals.

2. High Strength-to-Weight Ratio

Titanium is incredibly strong yet lightweight. This makes it a preferred material in industries like aerospace and automotive, where every ounce of weight saved can contribute to improved performance and fuel efficiency.

3. Long-Term Durability

The durability of titanium flange bolts ensures that they maintain their functionality over long periods, even in the harshest environments. This can reduce the frequency of maintenance or replacement, ultimately saving money and increasing the lifespan of the machinery or structure.

4. Resistance to High Temperatures

Titanium can withstand high temperatures, which is why it is often used in applications that require resistance to heat, such as in jet engines, power plants, and chemical reactors.

5. Reduced Maintenance Costs

Because titanium flange bolts last longer and are more resistant to wear and corrosion, they reduce the need for frequent replacements. This translates into lower maintenance costs and less downtime for equipment or structures.

Conclusion

Titanium flange bolts are an invaluable component in industries where strength, weight reduction, and corrosion resistance are top priorities. Their advantages over traditional fasteners, such as stainless steel, make them the ideal choice for applications in aerospace, marine, chemical, automotive, and medical fields. Whether you're working on high-performance vehicles, offshore platforms, or chemical reactors, choosing titanium flange bolts will ensure durability, performance, and safety, all while reducing long-term maintenance costs.

References

-

Smith, J.R. (2021). "Advanced Materials in Aerospace: The Role of Pure Titanium". Journal of Aerospace Engineering, 45(3), 234-248.

-

Johnson, A.M. & Williams, P.K. (2020). "Biocompatibility of Titanium in Medical Implants: A Comprehensive Review". Biomaterials Science, 8(12), 3301-3320.

-

Chen, Y., et al. (2019). "Corrosion Behavior of Pure Titanium in Marine Environments". Corrosion Science, 152, 120-133.

-

Patel, R.N. & Thompson, L.E. (2022). "Manufacturing Processes for High-Quality Titanium Plates". Advanced Materials Processing, 180(5), 45-58.

-

Garcia, M.S., et al. (2023). "Applications of Pure Titanium in Sustainable Architecture". Architectural Engineering and Design Management, 19(2), 178-195.

Learn about our latest products and discounts through SMS or email