Understanding the Advantages of Titanium Motorcycle Disc Bolts

Superior Material Properties

Titanium motorcycle disc bolts are crafted from Grade 5 titanium alloy (Ti6Al4V), which boasts an impressive array of properties that make it ideal for high-performance racing applications. This material offers an exceptional strength-to-weight ratio, allowing for significant weight reduction without compromising structural integrity. The low density of titanium, approximately 60% that of steel, translates to lighter components and improved overall bike performance.

Moreover, titanium's inherent corrosion resistance ensures that these bolts maintain their integrity even in harsh environments. This characteristic is particularly valuable in racing scenarios where exposure to various chemicals, moisture, and temperature fluctuations is common. The material's ability to withstand these conditions without degradation contributes to the longevity and reliability of the bolts, reducing the need for frequent replacements and maintenance.

Enhanced Performance on the Track

The use of titanium motorcycle disc bolts can have a noticeable impact on a bike's performance during races. The reduced weight of these components contributes to lower rotational mass in the wheel assembly, which can improve acceleration and handling. This weight reduction, though seemingly minor, can make a significant difference in competitive racing where fractions of a second can determine the outcome.

Additionally, the high tensile strength of titanium bolts, typically around 950 MPa, ensures they can withstand the extreme forces experienced during high-speed racing and aggressive braking. This strength is crucial for maintaining the integrity of the brake disc assembly, providing racers with confidence in their bike's stopping power and overall safety.

Customization and Aesthetic Appeal

Titanium motorcycle disc bolts offer a range of customization options to meet specific racing requirements. Manufacturers like Baoji Chuanglian New Metal Material Co., Ltd. provide these bolts in various thread sizes, including M6, M8, and M10, as well as custom sizes to fit different bike models and racing specifications. The ability to tailor the bolt length to exact requirements ensures optimal fitment and performance.

Furthermore, titanium bolts can be finished in various ways to enhance their appearance and functionality. Polishing can create a sleek, professional look, while anodizing allows for a range of color options including gold, blue, green, purple, black, and even rainbow effects. This not only adds a personal touch to the bike but can also aid in quick visual inspections during pit stops.

Maximizing Racing Performance with Titanium Disc Bolts

Weight Reduction Strategies

In the competitive world of motorcycle racing, every gram counts. Implementing titanium motorcycle disc bolts as part of a comprehensive weight reduction strategy can yield significant benefits. By replacing standard steel bolts with titanium alternatives, racers can achieve a notable weight savings in the wheel assembly. This reduction in unsprung weight can lead to improved suspension response and better overall handling characteristics.

To maximize the impact of titanium disc bolts, racers often combine their use with other lightweight components such as carbon fiber wheels or titanium axles. This holistic approach to weight reduction can result in a motorcycle that is more agile, quicker to accelerate, and easier to maneuver through tight corners – all crucial factors in gaining a competitive edge on the racetrack.

Durability and Maintenance Considerations

While the initial cost of titanium motorcycle disc bolts may be higher than that of standard steel alternatives, their long-term durability often results in cost savings over time. The superior corrosion resistance of titanium means these bolts are less likely to seize or degrade, even under extreme racing conditions. This reliability translates to reduced maintenance time and fewer replacements, allowing race teams to focus on other aspects of bike preparation and performance tuning.

To ensure optimal performance and longevity of titanium disc bolts, proper installation and periodic inspection are essential. Using the correct torque specifications during installation prevents over-tightening, which could lead to bolt failure. Regular visual checks for any signs of wear or damage, particularly after high-stress race events, can help identify potential issues before they become critical.

Safety and Compliance in Racing

When selecting titanium motorcycle disc bolts for racing applications, it's crucial to consider safety standards and racing regulations. High-quality titanium bolts, such as those produced by reputable manufacturers, are designed to meet or exceed industry safety standards. This ensures that the bolts can withstand the extreme forces and temperatures encountered during high-speed racing without compromising the structural integrity of the brake system.

Racers and teams should always verify that the titanium bolts they choose comply with the specific regulations of their racing series or event. Some organizations may have restrictions on material types or require certification for critical components. Working with established manufacturers who can provide documentation on material properties and testing results can help ensure compliance and avoid potential disqualification issues.

Choosing the Right Titanium Disc Bolts for Your Racing Needs

Assessing Quality and Specifications

When selecting titanium motorcycle disc bolts for racing applications, it's essential to carefully evaluate the quality and specifications of the products. Look for bolts made from Grade 5 titanium alloy (Ti6Al4V), which offers the optimal balance of strength, weight, and durability. Reputable manufacturers should be able to provide detailed material certifications and test results to verify the bolts' properties.

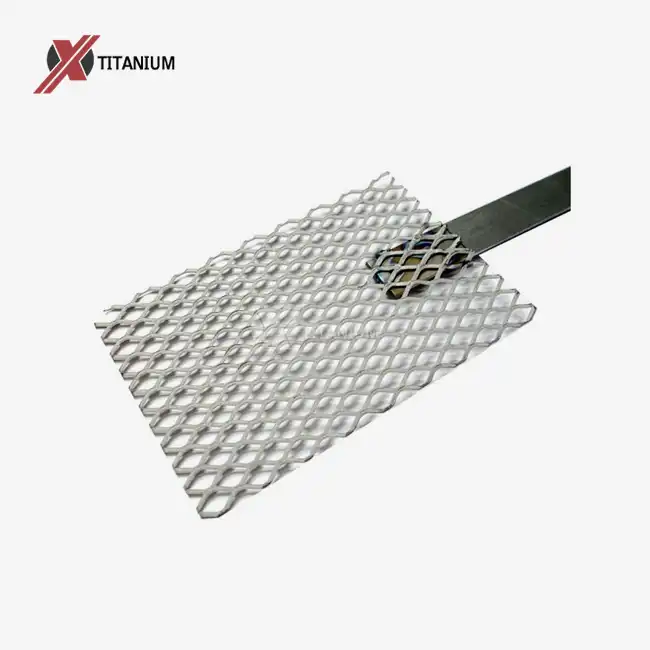

Pay close attention to the bolt specifications, including thread size, pitch, and length, to ensure compatibility with your specific motorcycle model and brake system. High-quality titanium bolts should have precise threading and a smooth finish to facilitate easy installation and removal. Consider bolts with additional features such as drilled heads for safety wire, which can be crucial in certain racing categories.

Evaluating Cost-Effectiveness

While titanium motorcycle disc bolts may have a higher upfront cost compared to standard steel bolts, it's important to consider their long-term value. Factor in the potential performance gains, weight savings, and increased durability when assessing the overall cost-effectiveness. In many cases, the initial investment in high-quality titanium bolts can be offset by improved race results and reduced maintenance costs over time.

Compare prices and specifications from multiple reputable suppliers to ensure you're getting the best value for your investment. Be wary of exceptionally low-priced titanium bolts, as these may be made from inferior materials or have substandard manufacturing processes that could compromise safety and performance.

Manufacturer Reputation and Support

Choosing titanium motorcycle disc bolts from a well-established manufacturer like Baoji Chuanglian New Metal Material Co., Ltd. can provide additional benefits beyond the product itself. Reputable manufacturers often offer superior customer support, technical assistance, and warranty coverage. This can be invaluable when dealing with high-performance racing components where precision and reliability are paramount.

Research the manufacturer's track record in the racing industry and look for testimonials or endorsements from professional teams or riders. A company with a strong presence in motorsports is more likely to understand the specific needs of racers and provide products that meet the demanding requirements of competitive racing.

Conclusion

Titanium motorcycle disc bolts represent a significant advancement in racing technology, offering an optimal blend of strength, lightweight construction, and durability. By carefully selecting high-quality titanium bolts from reputable manufacturers, racers can enhance their bike's performance, reduce maintenance time, and gain a competitive edge on the track. As the motorsports industry continues to push the boundaries of performance, titanium components like these bolts will undoubtedly play an increasingly important role in achieving success on the racetrack.

For more information about our high-quality titanium motorcycle disc bolts and other titanium products, please contact us at info@cltifastener.com or djy6580@aliyun.com. Our team of experts is ready to assist you in finding the perfect titanium solutions for your racing needs.