The Gr5 Titanium Seat Post Clamps

What is Gr5 Titanium?

Gr5 titanium, also known as Ti-6Al-4V, is a high-strength titanium alloy widely used in aerospace, marine, and cycling industries. This alloy contains 6% aluminum and 4% vanadium, which significantly enhance its mechanical properties. Gr5 titanium boasts an impressive strength-to-weight ratio, making it an ideal material for bicycle components like seat post clamps.

Benefits of Gr5 Titanium Seat Post Clamps

Gr5 titanium seat post clamps offer numerous advantages over traditional materials:

- Exceptional durability: With a tensile strength of 950 MPa and yield strength of 880 MPa, these clamps can withstand significant stress without deformation.

- Ultralight weight: The low density of 4.43 g/cm³ contributes to reducing overall bike weight.

- Corrosion resistance: Titanium's natural oxide layer provides excellent protection against rust and corrosion, even in harsh environments.

- Biocompatibility: For those with metal allergies, titanium is an excellent choice as it's hypoallergenic.

- Longevity: The combination of strength and corrosion resistance ensures these clamps will last for years, even with frequent use.

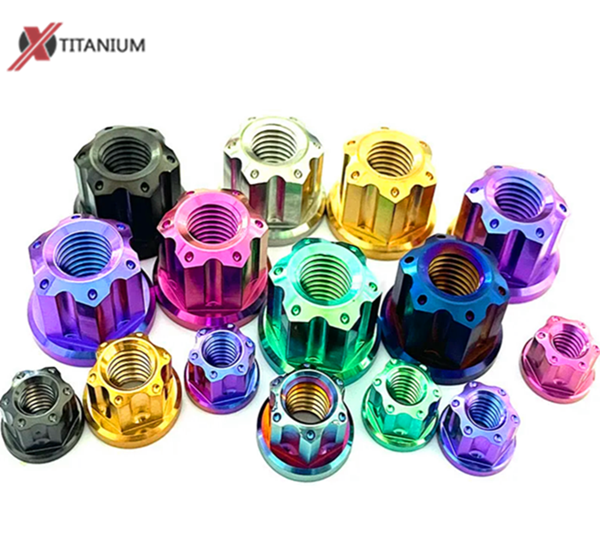

The Anodizing Process for Titanium Seat Post Clamps

What is Titanium Anodizing?

Titanium anodizing is an electrochemical process that creates a controlled oxide layer on the surface of the metal. This layer not only provides vibrant, interference-based colors but also significantly enhances the material's natural corrosion resistance and surface hardness. Unlike paint or powder coating, anodizing doesn't add a foreign layer; it transforms the surface itself, preserving the metal's dimensional integrity. The result is a long-lasting, uniform finish that won't chip, peel, or flake over time. Additionally, the anodized surface is biocompatible, making it ideal for both performance-driven and aesthetic applications in cycling and beyond.

Available Colors and Their Formation

The color of anodized titanium is determined by the thickness of the oxide layer, which is controlled by the voltage applied during the process. Common colors include:

- Gold: Achieved at lower voltages, often the first color in the spectrum.

- Purple: Requires a slightly higher voltage than gold.

- Blue: One of the most popular colors, achieved at mid-range voltages.

- Green: Requires precise voltage control to achieve.

- Black: The highest voltage setting, resulting in a deep, rich black.

It's worth noting that the exact shade can vary slightly depending on the specific composition of the titanium alloy and the anodizing conditions.

Benefits of Anodizing Titanium Clamps

Anodizing your Gr5 titanium seat post clamps offer several benefits beyond aesthetics:

- Enhanced corrosion resistance: The anodized layer provides additional protection against environmental factors.

- Increased surface hardness: Anodizing can increase the surface hardness to up to 36 HRC, improving wear resistance.

- Color stability: Unlike paint, anodized colors won't fade or chip over time.

- Customization: Allows for perfect color matching with other bike components.

- Maintains material properties: The anodizing process doesn't affect the strength or weight of the clamp.

Choosing and Maintaining Your Anodized Titanium Seat Post Clamp

Selecting the Right Clamp

When choosing a Gr5 titanium seat post clamp for anodizing, consider the following factors:

- Compatibility: Ensure the clamp diameter matches your seat post and frame specifications.

- Clamping mechanism: Look for designs that provide secure clamping without excessive pressure that could damage the seat post.

- Weight: While all titanium clamps are lightweight, small variations can matter for competitive cyclists.

- Finish quality: Choose a manufacturer known for high-quality machining and finishing processes.

Installation Tips

Proper installation of your anodized Gr5 titanium seat post clamp is crucial for both performance and aesthetics:

- Clean the seat post and frame before installation to ensure a secure fit.

- Apply a thin layer of anti-seize compound to prevent galling between the titanium surfaces.

- Tighten the clamp to the manufacturer's recommended torque specifications to avoid over-tightening.

- Use a torque wrench to ensure precise tightening and prevent damage to the anodized finish.

Maintenance and Care

Anodized Gr5 titanium seat post clamps are relatively low-maintenance, but proper care can ensure they remain in pristine condition:

- Regular cleaning: Wipe down the clamp with a soft, damp cloth to remove dirt and grime.

- Avoid abrasives: Don't use harsh chemicals or abrasive materials that could damage the anodized surface.

- Periodic inspection: Check for any signs of wear or loosening, especially after riding on rough terrain.

- Re-torque as needed: Occasionally check and re-tighten the clamp to the specified torque value.

Conclusion

Anodizing your Gr5 titanium seat post clamp is an excellent way to personalize your bike while maintaining the exceptional properties of titanium. The process allows for a range of vibrant colors that can complement or contrast with your bike's design. Beyond aesthetics, anodizing enhances the already impressive corrosion resistance and durability of titanium, ensuring your seat post clamp remains a reliable and visually appealing component for years to come.

If you're interested in exploring Gr5 titanium seat post clamps or other titanium components for your bike, don't hesitate to reach out to us at Baoji Chuanglian New Metal Material Co., Ltd. Our team of experts can provide guidance on selecting the right titanium products for your needs and discuss anodizing options. Contact us at info@cltifastener.com or djy6580@aliyun.com for more information.