Understanding Titanium Spring Washers: Properties and Applications

What are Titanium Spring Washers?

Titanium spring washers are specialized fastening components designed to provide tension, prevent loosening, and distribute load in various mechanical assemblies. These washers are crafted from high-grade titanium alloys, typically Grade 5 (Ti-6Al-4V), which offers an optimal balance of strength, weight, and corrosion resistance. The unique helical design of spring washers creates a spring-like effect when compressed, ensuring constant pressure and reducing the likelihood of bolt loosening due to vibration or thermal cycling.

Key Properties of Titanium Spring Washers

Titanium spring washers boast several exceptional properties that set them apart from their steel counterparts:

- Exceptional Strength-to-Weight Ratio: Titanium's high strength combined with its low density makes these washers incredibly strong yet lightweight, ideal for applications where weight reduction is crucial.

- Superior Corrosion Resistance: Titanium naturally forms a protective oxide layer, rendering it highly resistant to corrosion, even in harsh environments like saltwater or chemical processing plants.

- Temperature Resilience: These washers maintain their mechanical properties across a wide temperature range, from cryogenic conditions to high heat scenarios.

- Biocompatibility: Titanium's non-toxic nature and resistance to bodily fluids make it suitable for medical implants and devices.

- Low Thermal Expansion: Titanium's thermal expansion coefficient is lower than many metals, ensuring dimensional stability in temperature-varying environments.

Applications of Titanium Spring Washers

The unique properties of titanium spring washers make them invaluable in various high-performance applications:

- Aerospace: In aircraft and spacecraft construction, where weight reduction and reliability are paramount.

- Automotive Racing: High-performance engines and suspension systems benefit from titanium's strength and weight advantages.

- Marine Engineering: Offshore platforms and underwater equipment leverage titanium's corrosion resistance.

- Medical Devices: Surgical instruments and implants utilize titanium's biocompatibility and durability.

- Chemical Processing: Titanium's resistance to aggressive chemicals makes it ideal for equipment in corrosive environments.

- Renewable Energy: Wind turbines and solar panel mountings benefit from titanium's longevity and weather resistance.

Manufacturing Process and Quality Control of Titanium Spring Washers

Raw Material Selection and Preparation

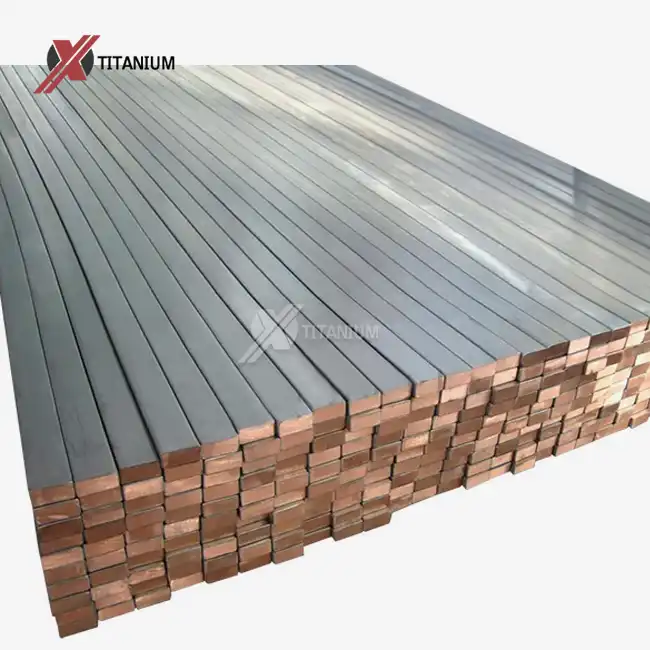

The manufacturing process of titanium spring washers begins with the careful selection of high-grade titanium alloys. Grade 5 titanium (Ti-6Al-4V) is often the material of choice due to its optimal balance of strength, ductility, and machinability. The raw titanium is typically sourced in the form of rods or sheets, depending on the manufacturing method to be employed. Before processing, the material undergoes rigorous quality checks to ensure it meets the required specifications for chemical composition and mechanical properties.

Fabrication Techniques

Several manufacturing methods can be employed to produce titanium spring washers, each with its own advantages:

- CNC Machining: Computer Numerical Control (CNC) machines are used to precisely cut and shape titanium into spring washers. This method allows for high accuracy and is ideal for producing custom or small batches of washers.

- Stamping: For larger production runs, stamping presses can be used to cut and form titanium sheets into spring washers. This method is efficient for high-volume production but may require significant initial tooling costs.

- Wire Forming: Some types of spring washers can be produced by coiling titanium wire and then cutting it into individual washers. This method is particularly suitable for certain styles of wave washers.

- Additive Manufacturing: Although less common, 3D printing technologies are emerging as a potential method for producing complex titanium components, including spring washers with unique geometries.

Heat Treatment and Surface Finishing

After the initial forming process, titanium spring washers often undergo heat treatment to optimize their mechanical properties. This process can include solution treating and aging to enhance strength and durability. Following heat treatment, various surface finishing techniques may be applied:

- Polishing: To achieve a smooth surface finish and improve corrosion resistance.

- Anodizing: An electrochemical process that creates a durable, decorative oxide layer, which can also be colored for identification purposes.

- Nitriding: A surface hardening treatment that improves wear resistance and fatigue strength.

Quality Control Measures

Stringent quality control is crucial in the production of titanium spring washers, especially for critical applications. Key quality assurance steps include:

- Dimensional Inspection: Precise measurements are taken to ensure washers meet specified tolerances.

- Material Testing: Samples undergo chemical analysis and mechanical testing to verify material properties.

- Load Testing: Spring washers are subjected to compression tests to evaluate their load-bearing capacity and spring characteristics.

- Corrosion Resistance Testing: Samples may be exposed to corrosive environments to confirm their resistance properties.

- Visual Inspection: Each washer is examined for surface defects or irregularities.

- Lot Traceability: Implementing a system to track each batch of washers from raw material to finished product ensures accountability and facilitates problem-solving if issues arise.

Advantages and Considerations of Using Titanium Spring Washers

Advantages of Titanium Spring Washers

Titanium spring washers offer numerous benefits that make them indispensable in certain applications:

- Weight Reduction: The low density of titanium allows for significant weight savings compared to steel washers, crucial in aerospace and high-performance automotive applications.

- Corrosion Resistance: Titanium's natural oxide layer provides excellent protection against corrosion, even in aggressive environments, reducing maintenance needs and extending service life.

- High Strength-to-Weight Ratio: Titanium washers can provide comparable or superior load-bearing capacity to steel washers while being much lighter.

- Temperature Resistance: These washers maintain their mechanical properties across a wide temperature range, making them suitable for both cryogenic and high-temperature applications.

- Biocompatibility: In medical applications, titanium's non-toxic nature and resistance to body fluids make it an excellent choice for implants and surgical instruments.

- Fatigue Resistance: Titanium's excellent fatigue strength ensures long-term reliability in applications subject to cyclic loading.

- Non-Magnetic Properties: Titanium's non-magnetic nature is advantageous in applications where magnetic interference must be avoided.

Considerations and Potential Drawbacks

While titanium spring washers offer numerous advantages, there are also some considerations to keep in mind:

- Cost: Titanium is generally more expensive than steel, which can impact the overall cost of components and assemblies.

- Galling Tendency: Titanium has a tendency to gall or seize when in contact with itself or certain other metals, requiring careful material selection for mating components.

- Limited Availability: Compared to steel, titanium components may have longer lead times or limited availability from suppliers.

- Specialized Manufacturing: Working with titanium often requires specialized equipment and expertise, which can limit manufacturing options.

- Design Considerations: Due to titanium's different mechanical properties compared to steel, existing designs may need to be modified when switching to titanium washers.

- Galvanic Corrosion: When used with dissimilar metals, proper insulation may be necessary to prevent galvanic corrosion.

Making the Right Choice

When considering titanium spring washers for an application, it's essential to weigh the advantages against the potential drawbacks and costs. In many high-performance or critical applications, the benefits of titanium - such as weight reduction, corrosion resistance, and long-term reliability - often outweigh the higher initial costs. Engineers and designers should carefully evaluate the specific requirements of their application, considering factors such as load requirements, environmental conditions, weight constraints, and lifecycle costs.

For applications where the unique properties of titanium are crucial, such as in aerospace, marine environments, or medical devices, titanium spring washers can provide unparalleled performance and reliability. However, for less demanding applications where traditional materials like steel perform adequately, the additional cost of titanium may not be justified.

Conclusion

Titanium spring washers represent a pinnacle of engineering in fastener technology, offering a unique combination of strength, lightweight properties, and corrosion resistance. While they may come with a higher initial cost, their superior performance in demanding environments and potential for long-term cost savings make them an invaluable choice for many high-performance applications.

For those considering the use of titanium spring washers or seeking more information about titanium products, it's advisable to consult with experts in the field. Baoji Chuanglian New Metal Material Co., Ltd., with its decade-long experience in titanium product manufacturing and research, stands ready to assist. For further inquiries or to discuss your specific needs, please contact us at info@cltifastener.com or djy6580@aliyun.com. Our team of specialists can provide insights into material selection, design considerations, and custom solutions to meet your unique requirements.