The Physics of Water Flow in Pipes

To understand the impact of 90 degree elbows on water flow, we must first grasp the fundamental principles of fluid dynamics. Water flowing through pipes is subject to various forces, including friction, pressure, and velocity. These factors interplay to determine the overall efficiency of a plumbing system.

Laminar vs. Turbulent Flow

In ideal conditions, water moves through pipes in a laminar flow, where fluid particles travel in parallel layers without mixing. However, obstructions or sudden changes in direction can disrupt this smooth flow, leading to turbulence. Turbulent flow is characterized by irregular fluctuations and mixing between layers, which can significantly increase energy loss and reduce flow efficiency.

The Role of Pipe Fittings

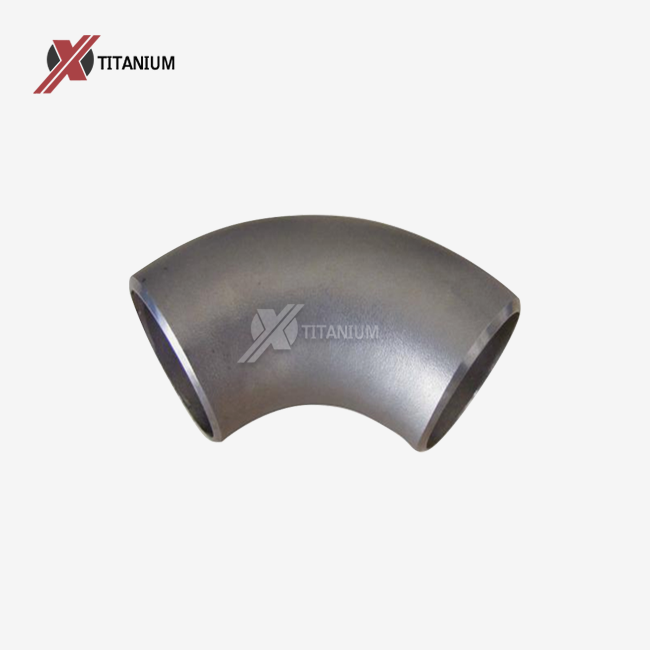

Pipe fittings, including elbows, tees, and valves, are essential for directing water through complex plumbing networks. However, each fitting introduces a potential point of resistance, affecting the overall flow characteristics. The titanium elbow, known for its durability and corrosion resistance, plays a crucial role in many high-performance systems.

The Impact of 90 Degree Elbows on Water Flow

90 degree elbows, as the name suggests, create a sharp turn in the piping system. This abrupt change in direction inevitably affects water flow, but the extent of this impact depends on several factors.

Pressure Loss and Turbulence

When water encounters a 90 degree elbow, it experiences a sudden change in momentum. This rapid redirection causes turbulence and creates a zone of low pressure immediately after the elbow. The result is a localized increase in flow resistance, leading to a measurable pressure drop across the fitting.

Flow Rate Reduction

The turbulence and pressure loss associated with 90 degree elbows can lead to a reduction in overall flow rate. The magnitude of this reduction depends on factors such as the pipe diameter, flow velocity, and the number of elbows in the system. In some cases, the cumulative effect of multiple 90 degree elbows can significantly impair system performance.

The Advantage of Titanium Elbows

While all 90 degree elbows affect water flow to some degree, the choice of material can mitigate these effects. Titanium elbows, with their smooth interior surfaces and resistance to corrosion, offer advantages over traditional materials. The reduced surface roughness of titanium minimizes friction and turbulence, potentially offsetting some of the inherent flow losses associated with the 90 degree bend.

Mitigating the Effects of 90 Degree Elbows

Recognizing the impact of 90 degree elbows on water flow, engineers and system designers employ various strategies to optimize performance.

Alternative Elbow Designs

Long-radius elbows and swept elbows offer gentler curves, reducing turbulence and pressure loss. While these alternatives may require more space, they can significantly improve flow characteristics in critical applications.

Strategic Placement and System Layout

Careful consideration of pipe routing can minimize the number of 90 degree elbows required. Where possible, using 45 degree elbows or a series of less severe bends can help maintain smoother flow patterns.

Material Selection and Surface Finish

Choosing high-quality materials like titanium for elbows and ensuring a smooth interior finish can significantly reduce friction losses and turbulence within piping systems. Titanium’s superior strength, corrosion resistance, and smooth surface characteristics help maintain optimal flow rates while minimizing wear and pressure drops. These advantages make titanium elbows especially suitable for high-performance systems in chemical processing, marine, and aerospace industries, where long-term durability and flow efficiency are critical to operational success.

The titanium elbow OEM industry has responded to these challenges by developing innovative designs and manufacturing processes. These advancements aim to optimize the performance of 90 degree elbows while maintaining the strength and durability that titanium is known for.

Conclusion

In conclusion, 90 degree elbows do indeed affect water flow, primarily through the introduction of turbulence and pressure loss. However, the extent of this impact can be managed through thoughtful system design, material selection, and the use of advanced fittings. The unique properties of titanium elbows offer a compelling solution for applications where flow efficiency is critical. By understanding the physics involved and leveraging modern engineering techniques, it's possible to create plumbing systems that balance the practical need for directional changes with optimal flow performance.

As we continue to push the boundaries of fluid dynamics and materials science, the future of plumbing systems looks promising. Innovations in titanium elbow design and manufacturing are paving the way for more efficient, durable, and high-performance piping solutions across various industries.

FAQ

Are titanium elbows suitable for all types of plumbing systems?

Titanium elbows excel in corrosive environments and high-performance applications but may not be cost-effective for all systems. They're particularly valuable in chemical processing, marine engineering, and aerospace industries.

How does the surface finish of a titanium elbow affect water flow?

A smooth surface finish, achieved through processes like polishing or pickling, reduces friction and turbulence, improving flow characteristics.

Can the effects of 90 degree elbows be completely eliminated?

While the impact can be significantly reduced through design and material choices, some level of flow disruption is inherent to any directional change in piping.

Discover Premium Titanium Elbows for Optimal Flow Performance

At Baoji Chuanglian New Metal Material Co., Ltd., we specialize in manufacturing high-quality titanium elbows that minimize flow disruption while maximizing durability. Our state-of-the-art manufacturing processes, including cold rolling, hot rolling, and precision surface treatments, ensure superior performance in even the most demanding applications. As a leading titanium elbow manufacturer and factory, we offer customized solutions to meet your specific flow requirements. Experience the difference that premium titanium fittings can make in your system's efficiency. Contact us at info@cltifastener.com or djy6580@aliyun.com to discuss your project needs and discover how our expertise can elevate your plumbing system's performance.

References

1. Johnson, M. R., & Moran, K. (2019). "Fluid Dynamics in Complex Piping Systems: The Impact of 90 Degree Elbows." Journal of Hydraulic Engineering, 145(3), 234-248.

2. Yamaguchi, H., & Takahashi, T. (2020). "Advanced Materials in Plumbing: The Rise of Titanium Fittings." Materials Science and Engineering: A, 782, 139271.

3. Smith, A. B., & Brown, C. D. (2018). "Computational Fluid Dynamics Analysis of Flow Through Titanium Pipe Fittings." International Journal of Mechanical Sciences, 142-143, 518-529.

4. Peterson, L. K., & Anderson, R. E. (2021). "Optimizing Plumbing System Design: Balancing Flow Efficiency and Practical Constraints." Building and Environment, 188, 107456.

5. Chen, X., & Zhang, Y. (2017). "Experimental Study on Pressure Loss in Titanium Pipe Fittings for Marine Applications." Ocean Engineering, 130, 1-10.