The Role of Titanium Bicycle Bolts in Frame Durability

While titanium frames themselves don't rust, the components used to assemble the frame play a crucial role in maintaining its overall integrity. Titanium bicycle bolts are an essential part of this equation. These high-performance fasteners offer several advantages that complement the durability of titanium frames:

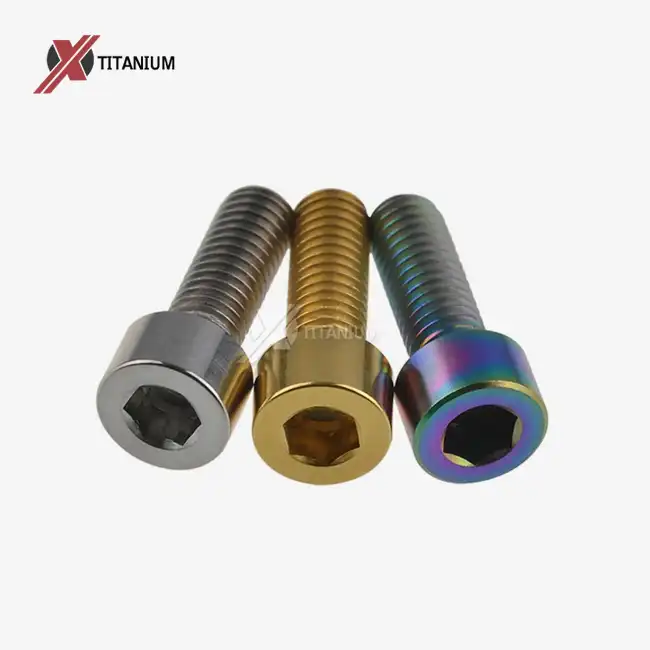

Corrosion Resistance of Titanium Bicycle Bolts

Titanium bicycle bolts share the same corrosion-resistant properties as titanium frames. This resistance is particularly important for bolts, as they are often exposed to moisture, sweat, and environmental contaminants. Unlike steel bolts that may rust and potentially compromise the frame's structural integrity, titanium bolts remain intact and functional even in challenging conditions. This corrosion resistance ensures that the connection points on your titanium frame remain secure and free from degradation over time.

Strength-to-Weight Ratio

Titanium bicycle bolts boast an impressive strength-to-weight ratio. They are significantly lighter than steel bolts while maintaining comparable or even superior strength. This characteristic aligns perfectly with the lightweight nature of titanium frames, allowing cyclists to maximize weight savings without sacrificing durability. The reduced weight of titanium bolts can contribute to improved overall bike performance, especially in competitive cycling where every gram counts.

Longevity and Maintenance

The durability of titanium bicycle bolts translates to extended longevity and reduced maintenance requirements. Unlike steel bolts that may need frequent replacement due to corrosion or wear, titanium bolts can last the lifetime of the frame with proper care. This longevity not only saves cyclists money in the long run but also ensures consistent performance and reliability throughout the bike's lifespan.

Advantages of Titanium Components in Bicycle Construction

The benefits of titanium extend beyond just frames and bolts. Various titanium components contribute to the overall performance and durability of high-end bicycles:

Titanium Seatposts and Handlebars

Titanium seatposts and handlebars offer a unique combination of strength, flexibility, and vibration damping. These properties enhance rider comfort by absorbing road vibrations more effectively than aluminum or carbon fiber alternatives. Additionally, the corrosion resistance of titanium ensures these components maintain their appearance and functionality even when exposed to perspiration and environmental elements.

Titanium Pedals and Cranks

Pedals and cranks made from titanium bicycle bolts provide exceptional durability and weight savings. These components are subjected to significant stress during cycling, and titanium's high strength-to-weight ratio makes it an ideal material choice. Titanium pedals and cranks can withstand intense use while resisting wear and corrosion, ensuring long-lasting performance for both recreational and competitive cyclists.

Titanium Spokes and Nipples

Wheel integrity is crucial for bicycle performance and safety. Titanium spokes and nipples offer superior fatigue resistance compared to traditional stainless steel options. This resistance to fatigue means that titanium-spoked wheels maintain their tension and true alignment for longer periods, reducing the need for frequent maintenance and enhancing overall wheel reliability.

Maintenance and Care for Titanium Bicycle Components

While titanium components, including frames and bolts, are known for their durability and corrosion resistance, proper maintenance can further extend their lifespan and preserve their performance:

Cleaning and Inspection

Regular cleaning of titanium components helps prevent the buildup of dirt and grime that could potentially lead to wear. Use a mild soap and water solution for routine cleaning, avoiding harsh chemicals that may damage the protective oxide layer. After cleaning, inspect titanium bicycle bolts and other components for any signs of damage or unusual wear. This proactive approach allows you to address any issues before they escalate.

Proper Torque and Assembly

When introducing or altering titanium bike jolts, it's pivotal to utilize the redress torque determinations. Over-tightening can lead to push on the components, whereas under-tightening may result in free associations. Utilizing a torque torque guarantees that all jolts are fixed to the manufacturer's suggested details, keeping up the astuteness of both the jolts and the outline.

Lubrication Considerations

While titanium components are naturally corrosion-resistant, proper lubrication can enhance their performance and prevent galling (a form of wear caused by adhesion between sliding surfaces). When assembling titanium parts or applying titanium bicycle bolts, use a thin layer of anti-seize compound specifically designed for titanium. This precaution prevents the components from binding and facilitates future disassembly if needed.

Conclusion

Titanium bike frames and components, including titanium bicycle bolts, offer unparalleled durability, corrosion resistance, and performance benefits. Their ability to withstand rust and maintain structural integrity over time makes them an excellent investment for cyclists seeking long-lasting, high-performance bicycles. By understanding the unique properties of titanium and following proper maintenance practices, cyclists can enjoy the benefits of this remarkable material for years to come.

For more information about titanium bicycle components and custom solutions, please contact Baoji Chuanglian New Metal Material Co., Ltd. at info@cltifastener.com or djy6580@aliyun.com. Our team of experts is ready to assist you in finding the perfect titanium solutions for your cycling needs.