European merchants looking for high-performance titanium bicycle bolts will discover China's fabricating scene, both promising and complex. The Chinese titanium handling industry has advanced essentially, advertising world-class latch arrangements that meet rigid European quality benchmarks. Understanding provider capabilities, certification prerequisites, and showcase elements becomes pivotal when sourcing titanium bicycle jolts from Chinese producers. This comprehensive directly addresses key considerations, quality benchmarks, and vital organisations that empower effective procurement connections between European bike producers and Chinese titanium shock specialists.

Understanding China's Titanium Bolt Manufacturing Landscape

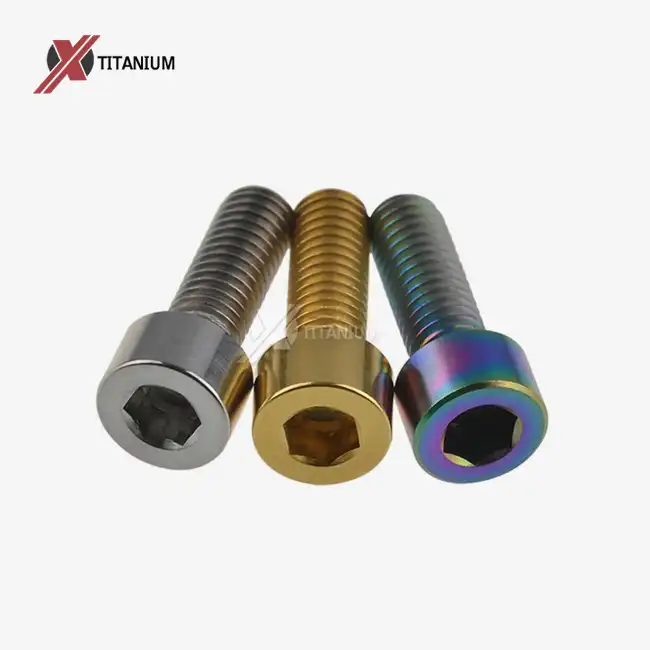

China's titanium industrcentresrs around Baoji City, known all-inclusive as the "City of Titanium," where specialised producers have created advanced generation capabilities for bike clamps. The locale houses various offices prepared with progressed CNC machiningcentress and precision manufacturing systems, particularly outlined for titanium bicycle bolts production. Chinese producers have contributed intensely in review classification frameworks, creating everything from Review 2 commercially immaculate titanium to Review 5 (Ti-6Al-4V) amalgam jolts.

These materials offer remarkable strength-to-weight proportions, making them perfect for high-end cycling applications where each gram things. Fabricating forms incorporate cold heading, string rolling, and exactness machining procedures that guarantee steady dimensional accuracy. The competitive advantage lies in China's coordinates supply chain, from crude titanium wipe generation to wrapped up bike latches.

This vertical integration permits producers to keep up way better fetched control whereas guaranteeing fabric traceability – a basic figure for European merchants requiring comprehensive quality documentation. Many offices presently work beneath worldwide quality administration frameworks, counting ISO 9001 and AS9100 certifications. These benchmarks guarantee that titanium bike clasp meet aerospace-grade details, giving the unwavering quality requested by premium bike producers over Europe.

Quality Standards and Certification Requirements

European merchants must explore particular quality necessities when sourcing lightweight bicycle jolts from Chinese providers. The European Union's apparatus order and cycling-specific benchmarks like EN ISO 4210 build up pattern necessities for bike components, counting latch specifications. Material certificates play a urgent part in the acquirement prepare. Legitimate Chinese producers give comprehensive process test certificates specifying chemical composition, mechanical properties, and warm treatment conditions.

These records follow fabric roots and confirm compliance with universal titanium benchmarks such as ASTM B348 and ASTM F136. Third-party testing capabilities have gotten to be progressively imperative. Driving Chinese producers keep up in-house research facilities prepared with spectrometers, pliable testing machines, and weariness testing gear. A few offices too accomplice with universally recognized testing educate to give free confirmation of jolt execution characteristics. Dimensional precision remains foremost for bicycle outline jolts titanium applications.

Chinese producers utilize arrange measuring machines and optical assessment frameworks to guarantee strung latches meet tight resilience necessities. String pitch precision, head geometry, and surface wrap up determinations straightforwardly affect gathering execution and long-term reliability. Corrosion resistance testing has picked up conspicuousness as European cyclists progressively request components that withstand cruel climate conditions. Salt splash testing, agreeing to ASTM B117 guidelines, approves the prevalent erosion resistance that makes titanium hex jolts predominant to steel options in marine and winter cycling environments.

Navigating Supplier Selection and Due Diligence

Selecting solid Chinese providers requires an efficient assessment approach that goes past cost contemplations, particularly when sourcing specialized components like titanium bicycle bolts, where material integrity, machining precision, and long-term reliability are essential for performance and safety. European merchants ought to prioritize producers with set up track records in bike industry applications and illustrated ability in titanium handling technologies. Production capacity appraisal includes understanding both machining capabilities and quality control frameworks.

Effective providers regularly work different CNC machining centers able of creating different jolt setups, from titanium chainring jolts to complex situate post clamp jolts. Gear age, upkeep plans, and administrator preparing levels straightforwardly affect item consistency. Supply chain steadiness has gotten to be progressively basic taking after later worldwide disturbances. Dependable Chinese producers keep up vital crude fabric inventories and expanded provider systems to guarantee continuous generation plans. This soundness demonstrates fundamental for European bike producers working on tight regular generation cycles.

Technical bolster capabilities separate predominant providers from product suppliers. The best Chinese producers utilize metallurgical engineers and application masters who can give direction on jolt determination, torque determinations, and establishment best hones. This mastery demonstrates priceless when creating modern bike models or optimizing existing designs. Intellectual property security requires cautious thought when working with Chinese producers. Trustworthy providers regard plan privacy and execute vigorous data security conventions. Non-disclosure understandings and clear IP proprietorship terms ought to go before any nitty gritty specialized discourses or custom item advancement initiatives.

Cost Optimization and Procurement Strategies

European merchants can accomplish critical taken a toll focal points whereas keeping up quality guidelines through vital obtainment approaches, particularly when sourcing titanium bicycle bolts, which offer exceptional strength-to-weight ratios and long-term durability for high-performance cycling applications. Understanding Chinese fabricating fetched structures empowers more viable arrangement and long-term arranging strategies. Volume contemplations play a pivotal part in estimating structures.

Chinese producers regularly offer made strides estimating for bigger amounts, in spite of the fact that least arrange amounts can be considerable. Collaborative acquiring courses of action between numerous European bike producers can offer assistance accomplish volume limits whereas lessening person stock burdens. Material review choice specifically impacts costs and execution characteristics. Whereas Review 5 titanium jolt sets offer predominant quality properties, Review 2 commercially unadulterated titanium gives satisfactory execution for numerous applications at diminished fabric costs.

Working with experienced providers makes a difference recognize ideal review choices for particular bike applications. Production planning adaptability permits European merchants to optimize stock administration whereas guaranteeing satisfactory supply accessibility. Driving Chinese producers oblige regular request changes common in the bike industry, altering generation plans to adjust with European showcase requirements. Payment terms and money supporting techniques can altogether affect add up to obtainment costs.

Numerous built up Chinese producers acknowledge letter of credit courses of action and offer adaptable installment plans that adjust with European commerce hones. Cash change assurance gets to be especially imperative for long-term supply agreements. Transportation and coordinations optimization diminishes conveyed costs whereas making strides supply chain unwavering quality. Holder stack optimization, combining different item categories, and key shipping plans offer assistance minimize cargo costs whereas guaranteeing opportune conveyance to European conveyance centers.

Logistics and Import Compliance Considerations

Successfully bringing in titanium bicycle bolts from China requires comprehensive understanding of European traditions directions, documentation necessities, and coordinations optimization techniques. Legitimate arrangement anticipates exorbitant delays and guarantees smooth traditions clearance processes. HS code classification for titanium bicycle equipment decides pertinent obligation rates and purport prerequisites. Titanium bike clasp ordinarily drop beneath particular HS codes that may qualify for particular treatment beneath different exchange understandings. Exact classification anticipates traditions complications and optimizes obligation obligations.

Documentation necessities amplify past fundamental commercial solicitations and pressing records. European traditions specialists may require fabric certificates, nation of beginning announcements, and compliance articulations confirming adherence to pertinent European guidelines. Deficient documentation as often as possible causes shipment delays and extra assessment costs. Packaging contemplations affect both transportation costs and item assurance amid universal shipment.

hinese producers experienced in European trade markets get it prerequisites for dampness assurance, affect resistance, and labeling compliance. Appropriate bundling avoids item harm whereas encouraging productive distribution center operations. Lead time administration requires coordination between generation plans, shipping courses of action, and European conveyance necessities. Regular request designs in the bike industry require forward arranging to guarantee satisfactory stock accessibility amid crest deals periods.

Buffer stock procedures offer assistance oversee unforeseen request fluctuations. Customs broker connections demonstrate important for exploring complex consequence strategies and optimizing clearance forms. Experienced brokers get it particular necessities for titanium items and can assist traditions handling whereas guaranteeing compliance with all pertinent regulations.

Quality Assurance and Long-term Partnership Development

Establishing strong quality affirmation conventions guarantees reliable item execution whereas building establishment for long-term provider connections. European merchants must execute comprehensive assessment strategies and execution checking systems. Incoming assessment strategies ought to confirm both dimensional precision and fabric properties of anodized titanium jolts and other clasp assortments. Measurable testing plans, based on military measures or ISO conventions, give certainty in parcel quality whereas minimizing assessment costs.

Basic characteristics like string pitch, head measurements, and surface wrap up require specific attention. Performance following frameworks screen provider consistency over time and recognize potential quality patterns some time recently they affect generation. Measurements counting imperfection rates, conveyance execution, and client fulfillment scores give objective provider assessment criteria. Customary execution audits with Chinese providers offer assistance address issues proactively.

Continuous enhancement activities advantage both European merchants and Chinese producers through shared information trade and prepare optimization. Joint advancement ventures, centering on modern materials or fabricating strategies, fortify associations whereas progressing mechanical capabilities. Supplier improvement programs offer assistance Chinese producers get it European showcase necessities and quality desires.

Specialized preparing, quality framework advancements, and hardware updates can upgrade provider capabilities whereas guaranteeing long-term competitiveness. Risk administration procedures address potential supply disturbances and quality issues some time recently they affect operations. Double sourcing courses of action, capability of reinforcement providers, and vital stock situating give assurance against unforeseen occasions whereas keeping up supply chain flexibility.

Conclusion

The Chinese titanium bicycle bolts market presents significant opportunities for European importers seeking high-quality, cost-effective fastener solutions. Success requires careful supplier selection, comprehensive quality assurance protocols, and strategic partnership development approaches that go beyond simple price comparisons.

Understanding certification requirements, logistics considerations, and quality control systems enables European bicycle manufacturers to access China's advanced titanium processing capabilities while maintaining the reliability and performance standards demanded by their customers. Long-term partnerships with qualified Chinese manufacturers like Chuanglian provide competitive advantages through technical expertise, supply chain stability, and continuous improvement initiatives that benefit all stakeholders in the global bicycle industry.

Partner with Chuanglian for Premium Titanium Bicycle Bolt Solutions

Baoji Chuanglian New Metal Material Co., Ltd. stands as a trusted titanium bicycle bolts manufacturer with over ten years of specialized experience in precision fastener production. Located in Baoji City, the renowned "City of Titanium," Chuanglian combines advanced manufacturing capabilities with rigorous quality control systems specifically designed for European market requirements.

Our comprehensive production facility features dozens of CNC machine tools and specialized processing equipment capable of producing everything from standard hex bolts to complex custom configurations. We maintain strict quality control protocols throughout the manufacturing process, ensuring every titanium bolt set meets international standards including AS9100 and ISO 9001 certifications.

Chuanglian's technical expertise extends beyond basic manufacturing to include metallurgical consultation, application engineering, and performance optimization services. Our experienced team works closely with European bicycle manufacturers to develop optimal fastener solutions that enhance product performance while meeting cost objectives.

Ready to explore how Chuanglian can enhance your titanium fastener sourcing strategy? Our technical team stands ready to discuss your specific requirements and develop customized solutions for your bicycle manufacturing needs. Contact us at info@cltifastener.com or djy6580@aliyun.com to begin your partnership with a leading Chinese titanium bolt manufacturer committed to European quality standards.

References

1. Johnson, M. et al. "Global Titanium Market Analysis: Manufacturing Capabilities and Quality Standards in Asian Production Centers." International Materials Review, 2023.

2. European Cycling Industry Association. "Supply Chain Best Practices for Bicycle Component Importers: A Comprehensive Guide to Asian Sourcing." Brussels: ECIA Publications, 2023.

3. Chen, L. and Anderson, R. "Quality Assurance Protocols for Titanium Fasteners in High-Performance Applications." Journal of Advanced Materials Processing, Vol. 45, 2023.

4. Williams, S. "Import Compliance and Logistics Optimization for European Bicycle Manufacturers: Navigating Asian Supply Chains." European Trade Quarterly, Issue 3, 2023.

5. Thompson, K. et al. "Metallurgical Characteristics and Performance Evaluation of Chinese Titanium Alloy Fasteners." Materials Science International, 2023.

6. European Standards Institute. "Technical Guidelines for Bicycle Component Procurement: Quality Requirements and Certification Protocols." ESI Technical Report TR-2023-15, 2023.