The Manufacturing Process of Titanium Clevis Pins for Marine Applications

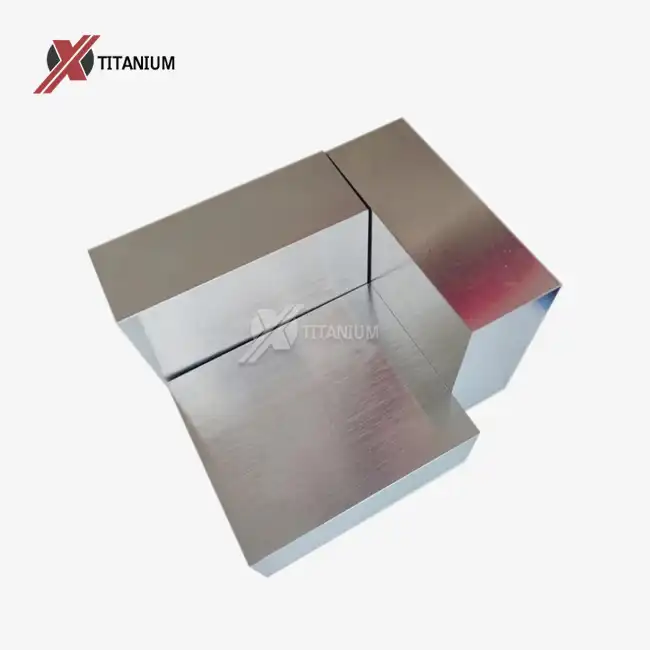

Raw Material Selection and Preparation

The production of high-quality titanium clevis pins begins with the careful selection of raw materials. Grade 5 titanium alloy (Ti6Al4V) is often the material of choice due to its exceptional strength-to-weight ratio and corrosion resistance. This alloy combines titanium with 6% aluminum and 4% vanadium, creating a robust material ideal for marine environments. The raw titanium undergoes rigorous testing to ensure purity and structural integrity before being processed into billets or bars.

CNC Machining and Precision Engineering

Once the raw material is prepared, the manufacturing process moves to the CNC machining phase. Computer Numerical Control (CNC) machines are programmed to cut, shape, and refine the titanium into precise clevis pin dimensions. This step is crucial for ensuring the pins meet exact specifications required for marine applications. The CNC process allows for high precision and repeatability, guaranteeing that each titanium clevis pin is manufactured to the same exacting standards.

Surface Treatment and Finishing

After machining, the titanium clevis pins undergo various surface treatments to enhance their performance and aesthetic appeal. These treatments may include polishing to achieve a smooth surface finish, anodizing to improve wear resistance and color options, or nitriding to increase surface hardness. Each treatment is carefully selected based on the specific requirements of the marine application. The resulting surface can range from the natural titanium color to vibrant hues like gold, blue, green, purple, black, or even a rainbow effect.

Quality Assurance and Testing of Titanium Clevis Pins

Adherence to International Standards

Quality assurance is paramount in the production of titanium clevis pins for marine engineering. Manufacturers adhere to stringent international standards such as ASTM B348 for titanium and titanium alloy bars and billets, AMS 4928 for aerospace material specifications, and ISO 9001 for quality management systems. These standards ensure that the titanium clevis pins meet or exceed the rigorous requirements of the marine industry.

Non-Destructive Testing (NDT) Techniques

To guarantee the structural integrity of each titanium clevis pin, manufacturers employ various non-destructive testing methods. These may include ultrasonic testing to detect internal flaws, magnetic particle inspection to identify surface and near-surface defects, and dye penetrant testing for surface imperfections. NDT techniques are crucial for identifying any potential weaknesses in the pins without compromising their usability.

Dimensional and Mechanical Property Verification

Each titanium clevis pin undergoes thorough dimensional checks to ensure compliance with specified tolerances. Advanced measuring equipment, such as coordinate measuring machines (CMMs), is used to verify critical dimensions. Additionally, mechanical properties such as tensile strength, yield strength, and elongation are tested to confirm that the pins meet the required performance criteria for marine applications. These tests ensure that the titanium clevis pins can withstand the extreme forces and conditions encountered in marine environments.

Distribution and Application of Titanium Clevis Pins in Marine Engineering

Supply Chain Management and Logistics

The distribution of titanium clevis pins to marine engineering projects requires efficient supply chain management. Manufacturers work closely with distributors and logistics partners to ensure timely delivery to shipyards, offshore facilities, and marine equipment manufacturers. Inventory management systems are employed to maintain optimal stock levels, balancing the need for immediate availability with cost-effective storage solutions. The distribution network must be capable of responding quickly to urgent requests, as downtime in marine operations can be extremely costly.

Applications in Shipbuilding and Offshore Structures

Titanium clevis pins find extensive use in shipbuilding and offshore structures due to their exceptional properties. In shipbuilding, they are used in various applications, including rigging systems, deck equipment, and propulsion components. The pins' corrosion resistance is particularly valuable in areas exposed to constant seawater contact. In offshore structures such as oil rigs and wind farms, titanium clevis pins are utilized in critical load-bearing connections, safety systems, and equipment mounting. Their high strength-to-weight ratio contributes to the overall efficiency and performance of these marine structures.

Maintenance and Replacement Considerations

The longevity of titanium clevis pins in marine applications is remarkable, but periodic maintenance and occasional replacement are necessary to ensure ongoing safety and performance. Marine engineers and maintenance crews rely on the availability of replacement pins through established distribution channels. The ease of sourcing compatible titanium clevis pins is crucial for minimizing downtime during maintenance operations. Additionally, the recyclability of titanium contributes to the sustainability of marine engineering practices, aligning with growing environmental concerns in the industry.

Conclusion

The journey of titanium clevis pins from manufacturing to distribution showcases the intricate processes and considerations involved in supplying critical components to the marine engineering sector. These unassuming yet vital fasteners play a significant role in ensuring the safety, efficiency, and longevity of marine structures and equipment. As marine engineering continues to evolve, the demand for high-performance materials like titanium clevis pins is likely to grow, driving further innovations in manufacturing, quality assurance, and distribution practices.

For more information about titanium products and their applications in marine engineering, please contact Baoji Chuanglian New Metal Material Co., Ltd. at info@cltifastener.com or djy6580@aliyun.com. Our team of experts is ready to assist you with your specific titanium fastener needs and provide tailored solutions for your marine engineering projects.