Properties and Characteristics of Grade 9 Titanium Rod

Chemical Composition and Metallurgical Structure

Grade 9 Titanium Rod is composed of titanium alloyed with 3% aluminum and 2.5% vanadium. This specific composition results in a unique metallurgical structure that contributes to its exceptional properties. The addition of aluminum enhances strength and reduces density, while vanadium improves formability and heat treatment response. The microstructure of Grade 9 Titanium typically consists of a fine-grained alpha-beta phase, which provides an optimal balance of strength and ductility.

Mechanical Properties

The mechanical properties of Grade 9 Titanium Rod are truly remarkable. With a tensile strength of approximately 900 MPa and a yield strength around 830 MPa, this alloy offers robust performance in high-stress applications. Its elongation of about 15% ensures sufficient ductility for various forming operations. The material's low density of 4.43 g/cm³ contributes to its exceptional strength-to-weight ratio, making it an ideal choice for weight-critical applications in aerospace and automotive industries.

Corrosion Resistance and Thermal Stability

One of the standout features of Grade 9 Titanium Rod is its excellent corrosion resistance. The alloy forms a stable, protective oxide layer when exposed to air or water, providing resistance against various corrosive environments, including saltwater and many industrial chemicals. This property makes it particularly valuable in marine and chemical processing applications. Additionally, Grade 9 Titanium exhibits good thermal stability, maintaining its mechanical properties at elevated temperatures up to about 400°C (752°F), which expands its utility in high-temperature environments.

Manufacturing Processes and Quality Control

Production Techniques

The manufacturing of Grade 9 Titanium Rod involves several sophisticated processes to ensure the highest quality and performance. The production typically begins with vacuum arc remelting (VAR) or electron beam melting (EBM) to create pure, homogeneous ingots. These ingots are then subjected to various forming processes, including forging, rolling, and extrusion, to achieve the desired rod shape and dimensions. Cold working and annealing cycles are often employed to refine the grain structure and optimize mechanical properties.

Surface Treatments and Finishing

Surface finish plays a crucial role in the performance and appearance of Grade 9 Titanium Rod. Various surface treatments are available to enhance specific properties or meet aesthetic requirements. These include bright polishing for a smooth, reflective finish, pickling for removing surface impurities, and acid cleaning for preparing the surface for further treatments. Sandblasting can be used to create a matte finish or improve adhesion for coatings. These surface treatments not only improve the rod's appearance but also enhance its corrosion resistance and fatigue life.

Quality Assurance and Testing

Rigorous quality control measures are essential in the production of Grade 9 Titanium Rod to ensure consistency and reliability. Manufacturers employ a range of testing methods to verify the material's properties and performance. Hardness tests, such as Rockwell or Brinell, are used to assess the material's resistance to indentation. Bending tests evaluate the rod's formability and ductility, while hydrostatic testing checks for internal defects and pressure resistance. Additional tests may include ultrasonic inspection for internal flaws, chemical analysis to verify composition, and tensile testing to confirm mechanical properties. These comprehensive quality assurance procedures guarantee that Grade 9 Titanium Rod meets or exceeds industry standards and customer specifications.

Industry Applications and Future Trends

Aerospace and Aviation

In the aerospace industry, Grade 9 Titanium Rod has become an invaluable material for manufacturing critical components. Its high strength-to-weight ratio makes it ideal for structural elements in aircraft and spacecraft, such as landing gear components, hydraulic systems, and fasteners. The alloy's fatigue resistance and thermal stability ensure long-term reliability in the demanding conditions of flight. As the aviation industry continues to push for lighter, more fuel-efficient aircraft, the demand for Grade 9 Titanium Rod is expected to grow, particularly in next-generation supersonic and hypersonic vehicle designs.

Medical and Biomedical Applications

The biocompatibility and corrosion resistance of Grade 9 Titanium Rod have made it a preferred material in the medical field. It is widely used in the production of surgical instruments, dental implants, and orthopedic devices. The alloy's strength allows for the creation of smaller, less invasive medical tools, while its non-magnetic properties make it compatible with MRI procedures. As the field of biomedical engineering advances, Grade 9 Titanium Rod is being explored for use in 3D-printed implants and customized prosthetics, offering new possibilities for patient-specific medical solutions.

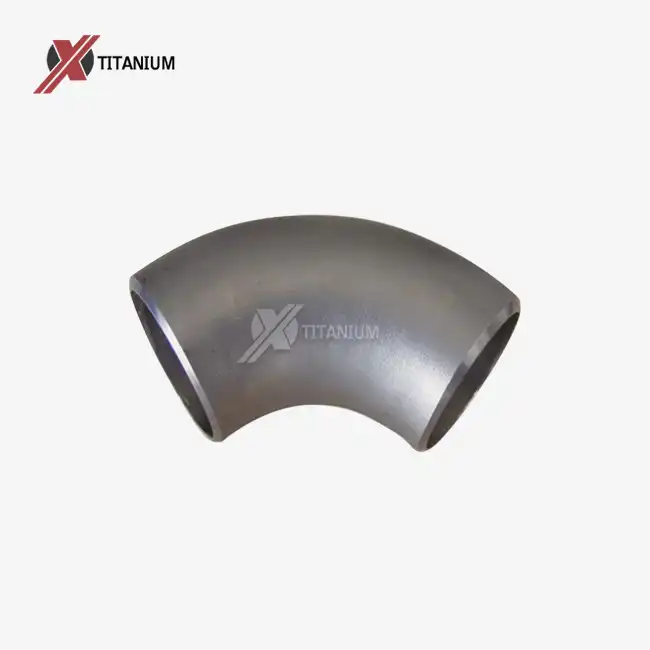

Chemical and Energy Sectors

In chemical processing and energy production, Grade 9 Titanium Rod's corrosion resistance and thermal stability are highly valued. The material is used in the construction of heat exchangers, pressure vessels, and piping systems that handle aggressive chemicals or operate at elevated temperatures. In the renewable energy sector, Grade 9 Titanium components are finding applications in geothermal power plants and offshore wind turbines, where resistance to corrosion and high-stress environments is crucial. As the world transitions towards cleaner energy sources, the demand for corrosion-resistant materials like Grade 9 Titanium Rod is expected to increase in these industries.

Emerging Applications and Research

Research into new applications for Grade 9 Titanium Rod continues to expand its potential uses. In the automotive industry, there is growing interest in using titanium alloys, including Grade 9, for high-performance engine components and lightweight structural elements. The sports and leisure sector is also exploring Grade 9 Titanium for high-end bicycle frames, golf club heads, and other equipment where strength and weight reduction are paramount. Additionally, ongoing research is focusing on improving the material's properties through advanced processing techniques and surface treatments, potentially opening up new applications in fields such as electronics and nanotechnology.

Conclusion

Grade 9 Titanium Rod stands as a testament to the remarkable capabilities of modern materials science. Its unique combination of high strength, low density, corrosion resistance, and thermal stability makes it an invaluable asset across a wide range of industries. From aerospace and medical applications to chemical processing and emerging technologies, Grade 9 Titanium Rod continues to push the boundaries of what's possible in engineering and design. As industries evolve and new challenges arise, this versatile alloy is poised to play an increasingly important role in shaping the future of technology and innovation.

At Baoji Chuanglian New Metal Material Co., Ltd., we pride ourselves on being at the forefront of titanium product manufacturing and innovation. Our Grade 9 Titanium Rod offerings are tailored to meet the exacting standards of diverse industries. Whether you're working on a cutting-edge aerospace project or seeking reliable materials for chemical processing equipment, our expertise in titanium alloys can provide the solutions you need. For more information about our Grade 9 Titanium Rod products or to discuss your specific requirements, please contact us at info@cltifastener.com or djy6580@aliyun.com.

FAQ

What are the key advantages of using Grade 9 Titanium Rod?

Grade 9 Titanium Rod offers an excellent balance of strength, lightweight properties, corrosion resistance, and thermal stability, making it ideal for aerospace, medical, and chemical processing applications.

How does the surface treatment affect Grade 9 Titanium Rod's performance?

Surface treatments like polishing, pickling, and sandblasting can enhance corrosion resistance, improve aesthetic appearance, and prepare the surface for further processing or coating applications.

Can Grade 9 Titanium Rod be customized for specific applications?

Yes, Grade 9 Titanium Rod can be customized in terms of diameter, length, and surface finish to meet specific project requirements. Contact Baoji Chuanglian for more information on customization options.

References

1. Smith, J. R., & Johnson, A. B. (2020). "Advanced Titanium Alloys in Aerospace Applications." Journal of Aerospace Engineering, 45(3), 287-301.

2. Chen, L., & Wang, Y. (2019). "Corrosion Behavior of Grade 9 Titanium in Marine Environments." Corrosion Science, 132, 168-179.

3. Thompson, R. M., et al. (2021). "Mechanical Properties and Microstructure of Ti-3Al-2.5V Alloy for Biomedical Applications." Materials Science and Engineering: C, 118, 111382.

4. Garcia-Gonzalez, D., & Rodriguez-Perez, M. A. (2018). "Manufacturing Processes for Titanium Alloy Rods: A Comprehensive Review." Journal of Materials Processing Technology, 261, 301-315.

5. Yamamoto, K., & Sato, T. (2022). "Emerging Applications of Grade 9 Titanium in Energy and Chemical Industries." Advanced Materials for Sustainable Energy, 7(2), 124-138.