The Unique Properties of Medical Titanium Rods

Biocompatibility and Osseointegration

Medical titanium rods have gained significant traction in the medical field due to their exceptional biocompatibility. This remarkable property stems from the formation of a stable oxide layer on the titanium surface, which effectively prevents adverse reactions with surrounding tissues. The biocompatibility of titanium allows for seamless integration with the human body, minimizing the risk of rejection or inflammation.

Moreover, titanium exhibits outstanding osseointegration capabilities. This process involves the direct structural and functional connection between living bone tissue and the implant surface. The porous structure of titanium promotes bone ingrowth, leading to a strong and stable interface between the implant and bone. This enhanced integration contributes to faster healing times and improved long-term stability of implants, making medical titanium rods an ideal choice for orthopedic and dental applications.

Corrosion Resistance and Durability

One of the most notable attributes of medical titanium rods is their superior corrosion resistance. The aforementioned oxide layer not only enhances biocompatibility but also serves as a protective barrier against corrosive elements. This resistance to corrosion is particularly crucial in the harsh biological environment of the human body, where implants are exposed to various fluids and chemical processes.

The durability of titanium rods extends beyond corrosion resistance. These implants demonstrate remarkable fatigue strength, allowing them to withstand repetitive stress and strain without failing. This property is essential for load-bearing applications, such as spinal fusion surgeries or joint replacements, where the implant must endure constant mechanical forces over an extended period.

Lightweight Nature and Strength-to-Weight Ratio

Medical titanium rods boast an impressive strength-to-weight ratio, offering robust mechanical properties while remaining surprisingly lightweight. This characteristic is particularly advantageous in medical applications, as it reduces the overall burden on the patient's body. The lightweight nature of titanium implants contributes to improved patient comfort and mobility, especially in cases where multiple or large implants are required.

Despite their low density, titanium rods maintain excellent mechanical strength. This combination of lightness and strength makes them ideal for use in various medical procedures, from small dental implants to larger orthopedic applications. The ability to provide substantial support without adding excessive weight to the body is a significant factor in the growing popularity of medical titanium rods among healthcare professionals and patients alike.

Applications and Benefits of Medical Titanium Rods

Orthopedic Surgeries and Implants

In the realm of orthopedic surgeries, medical titanium rods have revolutionized treatment options for a wide range of conditions. These versatile implants are extensively used in procedures such as joint replacements, fracture fixation, and spinal fusion surgeries. The biocompatibility and osseointegration properties of titanium ensure a strong bond between the implant and bone, promoting faster healing and reducing the risk of complications.

For instance, in total hip replacements, titanium rods serve as the femoral stem, providing a stable foundation for the artificial joint. The corrosion resistance of titanium is particularly beneficial in this application, as it minimizes the risk of metal ion release and subsequent tissue reactions. Similarly, in spinal fusion surgeries, titanium rods are used to stabilize the vertebrae, offering excellent support while allowing for some flexibility to mimic the natural spine movement.

Dental Implants and Prosthetics

The dental industry has also embraced the use of medical titanium rods, particularly in the field of dental implants. Titanium's biocompatibility and osseointegration capabilities make it an ideal material for creating artificial tooth roots. These implants fuse with the jawbone, providing a stable foundation for dental prosthetics such as crowns, bridges, or dentures.

The success rate of titanium dental implants is remarkably high, with many patients experiencing long-term benefits. The durability of titanium ensures that these implants can withstand the forces of biting and chewing, while their corrosion resistance prevents degradation in the oral environment. Moreover, the lightweight nature of titanium contributes to patient comfort, allowing individuals to adapt quickly to their new dental implants.

Cardiovascular and Neurological Applications

Beyond orthopedics and dentistry, medical titanium rods have found applications in cardiovascular and neurological procedures. In cardiovascular surgeries, titanium is used to create stents, heart valve components, and pacemaker casings. The material's biocompatibility and corrosion resistance are crucial in these applications, where long-term implantation in the bloodstream is necessary.

In neurosurgery, titanium rods and plates are employed for cranial reconstruction and spinal stabilization. The material's strength and lightweight properties make it suitable for these delicate procedures, where minimal interference with surrounding tissues is essential. Additionally, titanium's non-ferromagnetic nature allows patients with these implants to safely undergo MRI scans, a significant advantage in long-term patient care and monitoring.

Advancements and Future Prospects in Medical Titanium Rod Technology

Surface Modifications and Coatings

Recent advancements in medical titanium rod technology have focused on enhancing their already impressive properties through surface modifications and coatings. These innovations aim to improve osseointegration, reduce infection risks, and enhance overall implant performance. One such advancement is the development of nanostructured titanium surfaces, which increase the surface area for bone cell attachment and promote faster osseointegration.

Researchers have also explored various coatings for medical titanium rods, including hydroxyapatite and bioactive glass. These coatings can further enhance bone bonding and accelerate the healing process. Additionally, antimicrobial coatings are being developed to reduce the risk of implant-associated infections, a significant concern in orthopedic and dental surgeries. These surface treatments and coatings represent a promising direction in improving the long-term outcomes of titanium implants.

3D Printing and Customization

The advent of 3D printing technology has opened up new possibilities in the fabrication of medical titanium rods. This additive manufacturing technique allows for the creation of highly customized implants tailored to individual patient anatomy. The ability to produce complex geometries and porous structures enhances the potential for osseointegration and reduces the need for bone grafts in certain procedures.

Customized titanium implants offer several advantages, including improved fit, reduced surgery time, and potentially better functional outcomes. For instance, in spinal surgeries, 3D-printed titanium rods can be designed to match the patient's specific spinal curvature, providing optimal support and alignment. As 3D printing technology continues to evolve, it is expected to play an increasingly significant role in the production of personalized medical titanium rods.

Biodegradable Titanium Alloys

An emerging area of research in medical titanium rod technology is the development of biodegradable titanium alloys. These innovative materials are designed to provide temporary support during the healing process and then gradually degrade, eliminating the need for implant removal surgeries. This approach is particularly beneficial in pediatric orthopedics, where traditional permanent implants may interfere with bone growth.

Biodegradable titanium alloys typically incorporate elements such as magnesium or zinc, which allow for controlled degradation while maintaining the necessary mechanical properties during the healing phase. While still in the experimental stages, these materials show promise in reducing long-term complications associated with permanent implants and improving overall patient outcomes. As research progresses, biodegradable titanium alloys may revolutionize certain aspects of orthopedic and dental implant technologies.

Conclusion

Medical titanium rods have emerged as a superior choice in long-term medical implant applications, outperforming traditional materials like stainless steel. Their exceptional biocompatibility, corrosion resistance, and mechanical properties contribute to improved patient outcomes and reduced complication rates. The versatility of titanium allows for its use in a wide range of medical applications, from orthopedic and dental implants to cardiovascular and neurological devices. As technology continues to advance, innovations in surface modifications, 3D printing, and biodegradable alloys are set to further enhance the capabilities of medical titanium rods. A medical titanium rods factory plays a crucial role in driving these developments, promising to improve patient care, reduce recovery times, and enhance long-term functional outcomes across various medical specialties.

At Baoji Chuanglian New Metal Material Co., Ltd., we are committed to providing high-quality medical titanium rods that meet the most stringent industry standards. Our expertise in titanium product manufacturing and research allows us to offer innovative solutions for various medical applications. If you're interested in learning more about our medical titanium rods or other titanium products, please don't hesitate to contact us at info@cltifastener.com or djy6580@aliyun.com. Our team of experts is ready to assist you in finding the perfect titanium solution for your medical device needs.

FAQ

What are the main advantages of medical titanium rods over stainless steel?

Medical titanium rods offer superior biocompatibility, better osseointegration, higher corrosion resistance, and a lower modulus of elasticity compared to stainless steel. These properties lead to improved long-term outcomes and reduced complications.

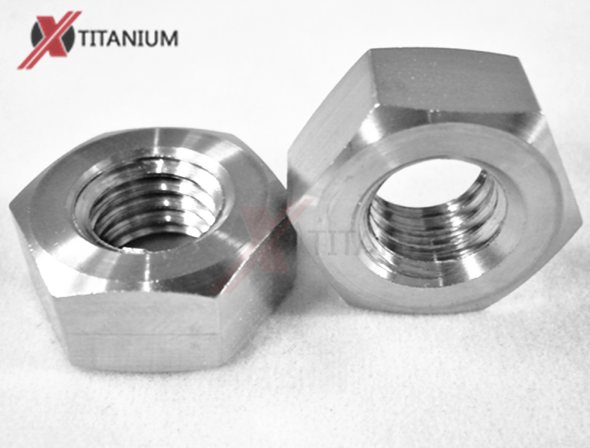

How are medical titanium rods manufactured?

Medical titanium rods can be manufactured through various techniques, including cold rolling, hot rolling, annealing, and pickling. The surface can be finished through processes like polishing, acid cleaning, or sandblasting to meet specific requirements.

What quality tests are performed on medical titanium rods?

Quality tests for medical titanium rods typically include hardness tests, bending tests, and hydrostatic tests. These ensure the rods meet the high standards required for medical applications.

References

1. Niinomi, M. (2019). Titanium alloys for biomedical applications. In Metals for Biomedical Devices (pp. 355-382). Woodhead Publishing.

2. Elias, C. N., Lima, J. H. C., Valiev, R., & Meyers, M. A. (2008). Biomedical applications of titanium and its alloys. JOM, 60(3), 46-49.

3. Bauer, S., Schmuki, P., von der Mark, K., & Park, J. (2013). Engineering biocompatible implant surfaces: Part I: Materials and surfaces. Progress in Materials Science, 58(3), 261-326.

4. Rack, H. J., & Qazi, J. I. (2006). Titanium alloys for biomedical applications. Materials Science and Engineering: C, 26(8), 1269-1277.

5. Long, M., & Rack, H. J. (1998). Titanium alloys in total joint replacement—a materials science perspective. Biomaterials, 19(18), 1621-1639.