- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How to Source Titanium Cotter Pins from China Factories

To get titanium cotter pins from Chinese makers, you need to carefully choose providers who can show that their materials can be tracked, they have quality certifications, and they can make specialized products. Made from Grade 2 or Grade 5 titanium metals, these split-pin screws play important locking roles in aircraft, naval, and industrial parts that need to be resistant to corrosion and light. China's manufacturing scene has low prices, flexible production numbers, and advanced CNC machining capabilities, which makes it a desirable place for procurement professionals looking for dependable titanium fastener providers. To get consistent performance in demanding situations, it's important to find makers with a history of good quality control and expert help.

Understanding Titanium Cotter Pins and Their Unique Benefits

Titanium cotter pins are a special kind of split-pin fastener that are designed to physically hold clevis pins, castle nuts, and slotted nuts in place in important assemblies where steel options would not work as well. These parts solve some of the most important engineering problems in high-performance settings by getting rid of the risks of galvanic rust and making materials stronger while using less weight.

Material Properties and Performance Characteristics

Titanium has unique qualities that make these fasteners essential in harsh settings. The mass of titanium cotter pins is about 4.51 g/cm³, which makes them 45% lighter than stainless steel counterparts while still having better tensile strength. The material's natural oxide film protects it from crack corrosion in saltwater, chlorides, and oxidizing acids up to 260°C. This resistance to rust is very important in chemical processing and naval undersea systems where chloride pitting can kill other 316 stainless steel fasteners.

Industrial Applications and Performance Requirements

Critical applications are used in many high-tech fields where failure would have very bad results. In flight uses, these fasteners hold together landing gear parts and UAV propulsion systems. Every gram of weight reduction helps aircraft use less fuel and carry more cargo. For propeller nuts and ROV systems that work in hypersaline environments, marine engineering counts on titanium cotter pins. These parts are used in racing for suspension setups and brake caliper bolts because they can handle high-frequency vibrations and thermal cycles without wearing out.

Titanium's non-magnetic property is very important in electrical equipment and MRI medical device parts, where magnetic interference could make them less useful. These fasteners are made to foreign standards like DIN94, ANSI B18.8.1, and ISO 1234, and they come in lengths that can be customized and sizes that range from 1.0 mm to 10 mm.

How to Identify Reliable Titanium Cotter Pin Manufacturers in China?

To find reliable Chinese makers, you need to carefully look at their technical skills, safety certifications, and production facilities. The titanium processing business has very strict quality standards, so checking with suppliers is very important for successful buying.

Essential Certifications and Quality Standards

Manufacturers with a good reputation keep a full set of certifications, such as ISO 9001 quality management systems, AS9100 aircraft certifications, and approvals specific to their business. These certificates show that you are dedicated to following quality control procedures and laws. Buyers should check that the materials they are interested in can get EN 10204 Type 3.1 Material Certification. This type of certification verifies the chemical make-up and mechanical qualities of certain heat lots used in production.

In factories with well-established quality control systems, strict testing procedures are used, such as checking the tensile strength, analyzing the chemical makeup, and making sure the measurements are correct. Modern makers keep material traceability tools that let them keep track of each batch as it is made.

Evaluating Manufacturing Capabilities and Infrastructure

China's titanium processing hubs, especially in places like Baoji City, have a lot of complex manufacturing know-how and tools. Manufacturers you can trust have complete CNC machining facilities that can make precision fasteners with the complicated shapes and close limits they need. Multiple CNC machines and automatic processing equipment show that the output capacity can be increased or decreased.

Leading sellers are different from commodity companies because they offer technical help. Manufacturers who give application engineering help, help with choosing the right custom metal, and suggestions for improving performance are great partners who go above and beyond just supplying products. Communication infrastructure that supports expert literature in English and quick customer service makes it easy for people in different time zones to work together.

Step-by-Step Sourcing Process for Titanium Cotter Pins from China

A organized method is needed for successful buying, starting with clear description of requirements and continuing through supplier review, sampling, and final supplier selection. This organized method lowers the chances of mistakes in quality while raising the efficiency of cost and service.

Specification Development and Technical Requirements

The buying process starts with making detailed specifications, which include choosing the right material grade, making sure the dimensions are accurate, making sure the surface is smooth, and making sure the product meets performance standards. For normal locking applications, Grade 2 commercially pure titanium is the most malleable. Grade 5 (Ti-6Al-4V), on the other hand, is best for high-shear uses that need more tensile strength, such as when choosing titanium cotter pins.

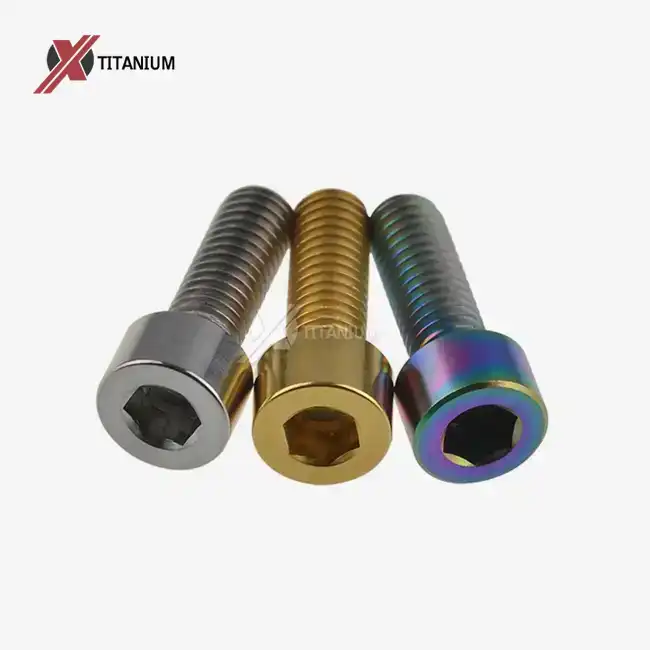

Custom specs could include anodized surface treatments to make the metal more resistant to corrosion or specific color needs to make the metal easy to identify. Titanium raw, gold, blue, green, purple, black, and colorful finishes are all colors that can be achieved through anodization. For specific uses, surface treatments like grinding and nitriding are also available.

Supplier Evaluation and Sample Procurement

In the evaluation phase, you ask for specific quotes that include certifications for materials, work schedules, and quality records. Suppliers with a good reputation give detailed technical data sheets, material test certificates, and documents on the production process. Sample sales let you check how well something works before you commit to buying a lot of it.

Minimum order amounts, price structures, shipping terms, and quality guarantees are all important parts of any discussion. Chinese makers usually give discounts for buying in bulk, but they keep their prices low for smaller special orders. To minimize cash flow and exchange rate threats, payment terms and currency deals need to be carefully thought out.

Independent quality checks for important applications are provided by third-party testing services. Professional inspection companies can do audits of factories, inspections of products while they are being made, and checks of finished goods to make sure they meet foreign standards and specs.

Comparing Titanium Cotter Pins to Alternatives: Making the Right Choice

Material choice has a big effect on how well a system works, how much upkeep it needs, and how much it costs over its whole life. Knowing the differences between products lets you make smart buying choices that meet the needs of the application and your budget.

Performance Comparison with Steel and Stainless Steel Options

Traditional steel cotter pins are cheaper to buy at first, but they can cause galvanic rusting if they are used with titanium or aluminum parts. The difference in electrical potential makes acidic cells, which quickly break down structures. Stainless steel is better at resisting corrosion, but it's not lighter, which is important for aircraft and racing uses.

Titanium's high strength-to-weight ratio lets parts be made smaller without affecting their function. This weight loss is especially helpful for spinning parts because less drag makes them respond better to changes in motion. Excellent wear resistance of the material guarantees stable performance under cyclic loading conditions common in places where vibrations are common.

Cost-Benefit Analysis and Lifecycle Considerations

Titanium screws are more expensive than steel ones, but lifetime cost analysis often suggests that titanium is the better choice. Long-term savings are big when you consider that the service life is extended, upkeep needs are lessened, and breakdowns caused by corrosion are eliminated. In marine uses, getting rid of corroded fasteners saves money on new prices and time because it cuts down on downtime.

Titanium is needed for medical devices that need to be safe for people because it blends well with living things. This specialized area of application gets high prices while making sure that regulations are followed and patients are safe.

Tips for Successful Bulk Purchasing and Custom Orders of Titanium Cotter Pins

For big projects like buying things and making them unique, you need to plan ahead and handle your relationships with suppliers to get the best results. To make good buying decisions, you need to know how volume price works and what customization options are available.

Volume Procurement Strategies and Pricing Optimization

A lot of the time, manufacturers use tiered price systems that give savings as the order size increases. When buyers know these price breaks, they can figure out the best amount to order to save the most money. To get good volume limits, needs can be merged across multiple projects or procurement processes can be lengthened.

Long-term contracts with chosen providers keep prices stable and make sure that capacity is allocated during times of high demand. Performance guarantees, priority scheduling for output, and technical support services that improve the total value offering, such as those related to titanium cotter pins, are common parts of these partnerships.

Customization Capabilities and Special Requirements

Leading makers offer a wide range of customization choices, such as non-standard sizes, markings, and packing needs that aren't standard. Specific application needs can be met by custom surface processes, material grades, and performance specs. Accurate product delivery depends on clear sharing of technical needs, such as drawings, specs, and performance criteria.

The standards for quality documentation depend on the business and how important the application is. For aerospace uses, it is common to need full material approvals, test records, and proof of traceability. Biocompatibility approvals and sterile packing choices are needed for medical uses.

Because they can be customized, companies like those in China's specialized titanium processing centers can give customers options that are exactly what they want while still keeping prices low and delivery times reliable.

Conclusion

Buying titanium cotter pins from China has a lot of benefits for sourcing workers who want to find high-quality fasteners at low prices. Systematic supplier review, detailed specification creation, and building strategic relationships with qualified makers are all important for success. Because China has improved production skills, low prices, and specialized knowledge in processing titanium, it is possible to save a lot of money while still getting good quality. Buyers can make sure they have a steady supply of these important fastening parts by using organized purchasing processes and giving priority to sellers with proven quality systems.

FAQ

What certifications should I request when sourcing titanium cotter pins from China?

Ask for EN 10204 Type 3.1 Material Certification at all times. This certifies the chemical make-up and mechanical qualities of the specific heat lot that was used in production. Also, make sure that providers keep their ISO 9001 quality management certification and any industry-specific approvals, like AS9100 for aircraft uses.

How do I choose between Grade 2 and Grade 5 titanium for cotter pin applications?

Grade 2 commercially pure titanium is easier to bend against nuts because it is more malleable and can be used for normal sealing uses. Grade 5 (Ti-6Al-4V) is stronger, but it has spring-back effects that can make it harder to place in most cotter pin situations.

Can titanium cotter pins be reused after removal?

No, you should never use titanium cotter pins more than once. As with all cotter pins, they stretch plastically when they are installed, and re-bending them makes the metal harder and more likely to break when they are used again.

What are typical lead times for custom titanium cotter pins from Chinese manufacturers?

Lead times depend on how complicated the customization is and how many items are ordered. Usually, it takes between 2 and 6 weeks for basic changes and 8 to 12 weeks for complex custom specs that need special tools or different types of material.

Partner with Chuanglian for Premium Titanium Cotter Pin Solutions

Chuanglian is a reliable titanium cotter pin manufacturer with over ten years of experience processing titanium and advanced CNC machining skills in Baoji City, China's famous "City of Titanium." Our strict quality control systems make sure that every fastener meets international standards like DIN94, ANSI B18.8.1, and ISO 1234, and we can customize the sizes from 1.0mm to 10mm with different surface treatments and anodized color choices. Get in touch with our technical team at info@cltifastener.com or djy6580@aliyun.com to talk about your unique needs and get full quotes that come with material certifications and performance guarantees.

References

1. Boyer, R., Welsch, G., & Collings, E.W. "Materials Properties Handbook: Titanium Alloys." ASM International Materials Engineering Publication, 2019.

2. International Titanium Association. "Titanium Fasteners in Industrial Applications: Performance and Specifications Guide." Technical Report Series, 2021.

3. Peters, M., & Leyens, C. "Aerospace and Space Applications of Titanium and Its Alloys." Manufacturing Engineering Society International Conference Proceedings, 2020.

4. Marine Technology Society. "Corrosion Resistance of Titanium Fasteners in Marine Environments: A Comparative Study." Ocean Engineering Research Journal, 2022.

5. American Society for Testing and Materials. "Standard Specifications for Titanium cotter Pins and Cotter Pins." ASTM F136-13 Standard Publication, 2023.

6. Chinese National Standards Committee. "Quality Control Standards for Titanium Fastener Manufacturing: Industrial Implementation Guidelines." GB/T Standards Documentation, 2022.

Learn about our latest products and discounts through SMS or email