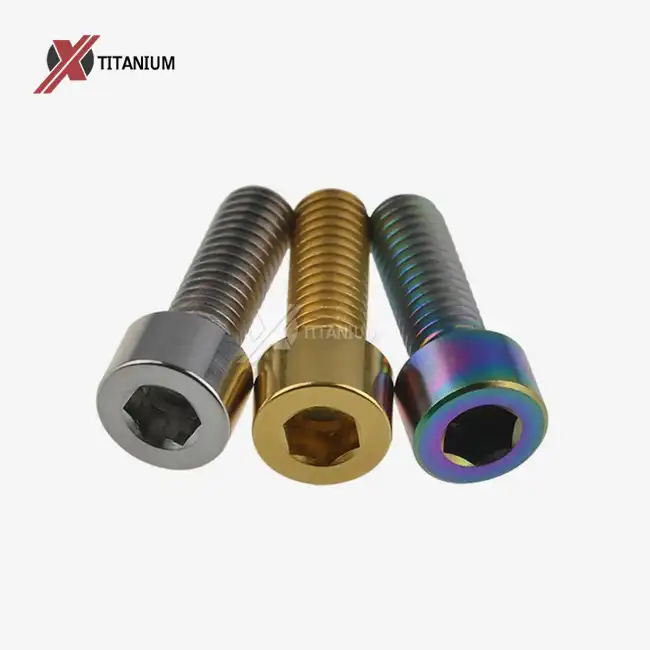

Grade 5 titanium, or Ti-6Al-4V, is a titanium alloy that has garnered significant attention across various industries due to its exceptional characteristics. This alloy contains 6% aluminum and 4% vanadium, which contribute to its superior properties compared to pure titanium. Let's delve into the remarkable attributes that make Grade 5 titanium a sought-after material in many applications, including the manufacturing of Gr5 titanium bicycle screws.

Strength-to-Weight Ratio

One of the most striking features of Grade 5 titanium is its impressive strength-to-weight ratio. This alloy boasts a tensile strength of around 900 MPa, which is comparable to many steels, yet it weighs only about 60% as much. This unique combination makes it an ideal choice for applications where both strength and weight savings are crucial, such as in the aerospace industry and high-performance bicycles. Gr5 titanium bicycle screws, for instance, offer the same or better strength as steel alternatives while significantly reducing the overall weight of the bicycle.

Corrosion Resistance

Grade 5 titanium exhibits exceptional resistance to corrosion, surpassing that of many other metals and alloys. This property stems from the formation of a stable, protective oxide layer on its surface when exposed to oxygen. This natural barrier shields the metal from chemical attacks, making it highly resistant to saltwater, acids, and other corrosive environments. For Gr5 titanium bicycle screws, this translates to long-lasting performance even in harsh weather conditions or when exposed to road salts and other corrosive substances.

Biocompatibility

Another noteworthy characteristic of Grade 5 titanium is its biocompatibility. The human body readily accepts this alloy, making it an excellent choice for medical implants and prosthetics. This property also ensures that Gr5 titanium bicycle screws are safe for use in applications where they may come into contact with human skin, such as in handlebar components or seat post clamps.

Applications of Grade 5 Titanium in the Cycling Industry

The cycling industry has embraced Grade 5 titanium for its unique combination of properties, leading to its use in various components, including Gr5 titanium bicycle screws. Let's explore how this remarkable alloy is transforming the world of cycling.

Lightweight Frame Construction

High-end bicycle manufacturers often use Grade 5 titanium in frame construction. The alloy's high strength-to-weight ratio allows for the creation of frames that are both lightweight and durable. These frames offer excellent ride quality, absorbing road vibrations while maintaining stiffness for efficient power transfer. Gr5 titanium bicycle screws play a crucial role in these frames, providing secure connections without adding unnecessary weight.

Performance-Enhancing Components

Beyond frames, Grade 5 titanium finds its way into various bicycle components. Handlebars, seat posts, and pedal spindles made from this alloy offer weight savings without compromising strength. Gr5 titanium bicycle screws are particularly valuable in these applications, as they provide secure fastening while contributing to the overall weight reduction of the bicycle. The corrosion resistance of these screws ensures that components remain easy to adjust or replace over time, even in challenging environments.

Durability in Mountain Biking

The mountain biking sector has also recognized the benefits of Grade 5 titanium. The alloy's ability to withstand impacts and resist corrosion makes it ideal for components that face harsh conditions. Gr5 titanium bicycle screws used in suspension pivots, for example, can withstand the constant movement and exposure to dirt and moisture without deteriorating. This durability translates to longer-lasting bikes that require less maintenance, a significant advantage for both recreational riders and professional athletes.

The Future of Grade 5 Titanium in Cycling and Beyond

As technology advances and manufacturing processes evolve, the potential applications for Grade 5 titanium in cycling and other industries continue to expand. Let's examine some emerging trends and future possibilities for this versatile alloy.

Advancements in 3D Printing

The realm of 3D printing is opening up new possibilities for Grade 5 titanium applications. As additive manufacturing techniques improve, it's becoming feasible to create complex titanium components with intricate internal structures. This could lead to even lighter and stronger bicycle parts, including customized Gr5 titanium bicycle screws tailored to specific load requirements. The ability to print titanium components could also reduce waste and lower production costs, making titanium bikes more accessible to a broader range of cyclists.

Integration with Smart Technologies

As bicycles become increasingly integrated with smart technologies, Grade 5 titanium's properties make it an excellent candidate for housing sensors and other electronic components. Its corrosion resistance and durability ensure that these delicate technologies remain protected in all weather conditions. Gr5 titanium bicycle screws could play a role in securing these smart components while maintaining the lightweight nature of high-performance bicycles.

Expanding into New Markets

While Grade 5 titanium has already made significant inroads in high-end cycling, there's potential for it to expand into broader markets. As production efficiencies improve and costs decrease, we may see Gr5 titanium bicycle screws and other components becoming more common in mid-range bicycles. This could bring the benefits of lightweight, durable, and corrosion-resistant components to a wider range of cyclists, improving the overall quality and longevity of bicycles across various price points.

Conclusion

Grade 5 titanium, while not bulletproof, offers a remarkable combination of properties that make it invaluable in numerous applications, particularly in the cycling industry. From lightweight frames to durable components like Gr5 titanium bicycle screws, this alloy continues to push the boundaries of what's possible in bicycle design and performance. As technology advances, we can expect to see even more innovative uses for Grade 5 titanium, potentially revolutionizing not just cycling, but various other industries as well.

For more information about Grade 5 titanium products, including Gr5 titanium bicycle screws, please don't hesitate to contact us at info@cltifastener.com or djy6580@aliyun.com. Our team of experts is ready to assist you with any questions or requirements you may have regarding titanium components for your cycling or other industrial needs.

_1742980398281.webp)