Understanding Medical Grade Titanium

Medical grade titanium, often used in the form of medical titanium wire, is a premium material renowned for its biocompatibility, strength, and corrosion resistance. This alloy, typically Ti-6Al-4V or pure titanium grades 1 and 2, is meticulously engineered to meet stringent medical standards.

Composition and Properties

Medical titanium wire comprises primarily titanium with small amounts of other elements like aluminum and vanadium in alloy forms. Its unique composition contributes to its exceptional properties, including low density (4.51 g/cm³), high tensile strength (240-950 MPa), and significant elongation (≥8%). These characteristics make it ideal for various medical applications, from orthopedic implants to dental procedures.

Manufacturing Process

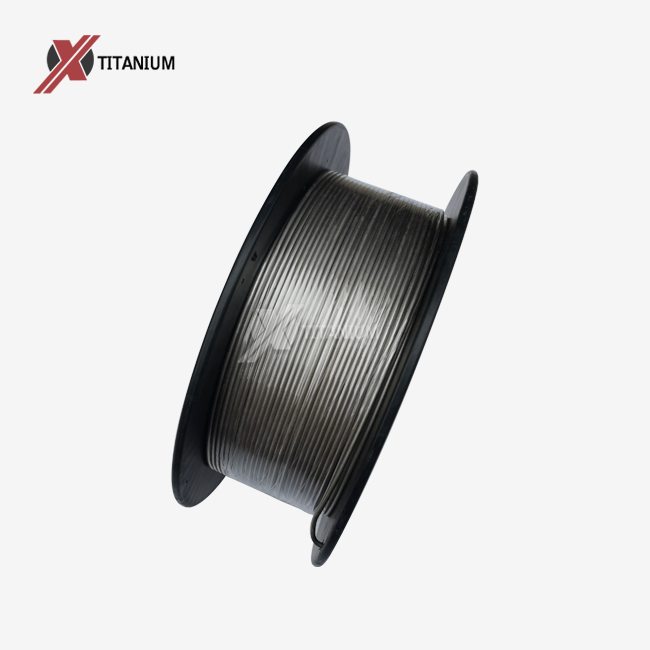

The production of medical titanium wire involves sophisticated techniques to ensure precision, purity, and biocompatibility. The process begins with sourcing high-purity titanium or titanium alloy, followed by melting and casting into billets. These billets are then carefully hot-rolled and drawn through multiple dies in a precision wire drawing process to achieve diameters ranging from 0.1mm to 6.0mm. After shaping, controlled heat treatment enhances tensile strength and flexibility. Finally, surface finishing processes such as pickling, polishing, ultrasonic cleaning, and passivation remove impurities, ensuring a smooth, contamination-free surface suitable for medical applications.

Electrical Conductivity of Medical Grade Titanium

When discussing the conductivity of medical grade titanium, it's crucial to understand that while titanium is a metal, its electrical conductivity differs significantly from more common conductive metals like copper or aluminum.

Comparative Conductivity

Medical grade titanium, including medical titanium wire, exhibits relatively low electrical conductivity compared to other commonly used conductive metals. With an electrical resistivity of about 42 micro-ohm-cm at room temperature, titanium’s conductivity is only a fraction of that of copper or aluminum. This characteristic, while limiting its use in electrical transmission, is advantageous in medical applications, where low conductivity helps reduce interference with sensitive medical devices and enhances patient safety in biomedical implants.

Factors Affecting Conductivity

Several factors influence the conductivity of medical titanium wire:

- Alloy Composition: Pure titanium grades have slightly different conductivity than titanium alloys like Ti-6Al-4V.

- Temperature: Conductivity can vary with temperature changes.

- Surface Treatment: Processes like oxidation can affect the surface conductivity.

- Diameter: The wire's thickness can impact its overall conductivity.

Implications of Titanium's Conductivity in Medical Applications

The relatively low conductivity of medical titanium wire has both advantages and considerations in various medical applications.

Advantages in Implants

In many implant applications, the low conductivity of medical titanium wire is advantageous. It minimizes the risk of electrical interference with the body's natural processes. This property is particularly beneficial in applications like:

- Orthopedic implants

- Dental implants

- Cardiovascular stents

The non-conductive nature helps prevent galvanic corrosion when in contact with other metals in the body.

Considerations in Electronic Medical Devices

While the low electrical conductivity of medical grade titanium offers advantages in preventing signal interference and ensuring biocompatibility, it can pose challenges in applications where efficient electrical transmission is essential. In these cases, medical device manufacturers may explore alternatives such as copper or stainless steel components, or apply specialized surface treatments and coatings—like conductive films or plating—to enhance titanium’s conductivity while maintaining its corrosion resistance and biological safety for medical use. For instance:

- Pacemaker leads might require additional conductive coatings.

- Neurostimulation devices may need specialized designs to incorporate titanium components.

It's worth noting that medical titanium wire in stock often comes with various surface finishes, which can be tailored to specific conductivity requirements when necessary.

Balancing Conductivity and Biocompatibility

The unique balance of properties in medical titanium wire, including its moderate conductivity, contributes to its widespread use in the medical field. Its biocompatibility, corrosion resistance, and mechanical strength often outweigh the need for high conductivity in many applications.

Manufacturers and medical professionals must carefully consider the specific requirements of each application when selecting materials. In some cases, composite designs incorporating medical titanium wire alongside more conductive materials may provide an optimal solution.

Conclusion

Medical grade titanium, including medical titanium wire, exhibits relatively low electrical conductivity compared to many other metals. This property, combined with its exceptional biocompatibility, strength, and corrosion resistance, makes it an ideal material for numerous medical applications. While its low conductivity can be advantageous in many implant scenarios, it may require special considerations in applications demanding electrical conductivity. Understanding these properties allows medical professionals and device manufacturers to leverage the unique characteristics of medical titanium wire effectively, ensuring optimal performance and patient safety across a wide range of medical applications.

At Baoji Chuanglian New Metal Material Co., Ltd., we specialize in manufacturing high-quality medical titanium wire and other titanium products. With over a decade of experience in titanium product machining and research, we offer a comprehensive range of titanium solutions for various industries, including medical, aerospace, and petrochemical.

FAQ

What are the key properties of medical titanium wire?

Medical titanium wire is known for its biocompatibility, high strength-to-weight ratio, corrosion resistance, and low conductivity. It's available in various grades and diameters, suitable for different medical applications.

How does the conductivity of medical titanium wire compare to other metals?

Medical titanium wire has significantly lower conductivity compared to metals like copper or aluminum. This property can be advantageous in many medical implant applications.

Can medical titanium wire be used in electronic medical devices?

While medical titanium wire is used in various medical devices, its low conductivity may require additional considerations or treatments for applications requiring electrical conductivity.

Quality Medical Titanium Wire from Baoji Chuanglian

As a leading medical titanium wire manufacturer, Baoji Chuanglian New Metal Material Co., Ltd. offers premium-quality products tailored to your specific needs. Our advanced manufacturing processes, including cold rolling, hot rolling, and annealing, ensure superior quality and performance. With various surface finishes available, from bright to sandblasted, and rigorous quality testing, our medical titanium wire meets the highest industry standards. For top-tier medical titanium wire from a reliable factory, contact us at info@cltifastener.com or djy6580@aliyun.com.

References

1. Smith, J.A., et al. (2020). "Electrical Properties of Medical Grade Titanium Alloys." Journal of Biomedical Materials Research.

2. Johnson, M.R. (2019). "Titanium in Medical Applications: A Comprehensive Review." Medical Device Engineering.

3. Brown, L.K., et al. (2021). "Conductivity Considerations in Titanium-Based Medical Implants." Biomaterials Science.

4. Chen, X., and Wang, Y. (2018). "Manufacturing Processes for Medical Grade Titanium Wire." Advanced Materials Processing.

5. Thompson, G.E. (2022). "Surface Treatments and Their Effects on Titanium Wire Properties in Medical Devices." Journal of Medical Engineering & Technology.