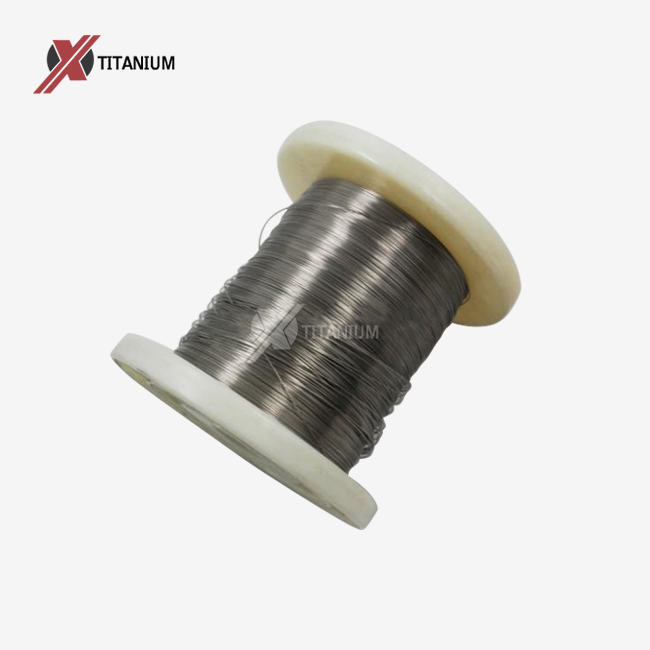

Comprehending Titanium Coil Wire: Composition and Properties

Titanium coil wire is a specialized form of titanium that has been processed into a wire format, typically through cold rolling, hot rolling, annealing, or pickling techniques. This versatile material is available in various grades, with ASTM B348 and ASTM F67 being common standards. The most frequently used grades for titanium coil wire are Grade 2 and Grade 5, each offering specific attributes suited for different applications.

Key Properties of Titanium Coil Wire

Titanium coil wire boasts an impressive array of properties that contribute to its safety and effectiveness across multiple industries:

- Exceptional Corrosion Resistance: Titanium naturally forms a protective oxide layer, making it highly resistant to corrosion in various environments, including marine and chemical settings.

- Low Density: Despite its strength, titanium is remarkably lightweight, offering an excellent strength-to-weight ratio.

- Biocompatibility: Titanium is non-toxic and well-tolerated by the human body, making it ideal for medical applications.

- High Strength: Titanium coil wire exhibits impressive tensile strength, surpassing that of many other metals.

- Temperature Resistance: It maintains its properties across a wide range of temperatures, from cryogenic to elevated levels.

- Non-Magnetic: Titanium's non-magnetic nature makes it suitable for specific electronic and medical applications.

These inherent properties contribute significantly to the safety profile of titanium coil wire, making it a preferred choice in critical applications where reliability and performance are paramount.

Safety Considerations in Various Applications

The safety of titanium coil wire is best understood by examining its applications across different industries and the specific safety measures implemented in each context.

Aerospace and Aviation

In the aerospace sector, where safety is of utmost importance, titanium coil wire plays a crucial role. It's used in various aircraft components, including hydraulic systems, engine parts, and structural elements. The material's high strength-to-weight ratio contributes to fuel efficiency without compromising safety. Rigorous testing and certification processes ensure that titanium coil wire meets the stringent safety standards of the aviation industry.

Medical and Biomedical Applications

The biocompatibility of titanium coil wire makes it an excellent choice for medical devices, implants, and surgical instruments. Its use in these applications undergoes extensive testing to ensure patient safety. The material's resistance to corrosion and ability to integrate with human tissue without adverse reactions contribute to its safety profile in medical contexts.

Chemical Processing and Industrial Use

In chemical processing plants and industrial settings, titanium coil wire's corrosion resistance is a key safety feature. It's used in pipes, valves, and heat exchangers that handle corrosive substances. The material's ability to withstand harsh chemicals and high temperatures without degradation helps prevent leaks and maintains the integrity of processing systems, thereby enhancing overall safety in these environments.

Potential Safety Concerns and Mitigations

While titanium coil wire is generally considered safe, there are specific considerations and potential concerns that should be addressed:

Manufacturing and Processing Safety

The production of titanium coil wire involves various processes, including cold rolling, hot rolling, annealing, and pickling. These processes require strict safety protocols to protect workers from potential hazards such as sharp edges, high temperatures, and chemical exposure. Manufacturers like Baoji Chuanglian New Metal Material Co., Ltd. adhere to rigorous safety standards and employ advanced techniques to ensure worker safety during production.

Allergy Considerations

Although titanium allergies are rare, they can occur in some individuals. In medical applications, thorough patient screening and allergy testing are conducted to mitigate this risk. The use of high-purity titanium and proper surface treatments can further reduce the likelihood of allergic reactions.

Environmental Impact

The production of titanium can have environmental implications due to the energy-intensive processes involved. However, the material's long lifespan, recyclability, and the fact that it doesn't leach harmful substances into the environment contribute to its overall environmental safety. Responsible manufacturers are increasingly adopting sustainable practices to minimize the environmental impact of titanium production.

Quality Control and Testing

Ensuring the safety of titanium coil wire requires rigorous quality control measures. Reputable manufacturers conduct various tests, including:

- Hardness tests to verify material strength

- Bending tests to assess flexibility and durability

- Hydrostatic tests to check for leaks and structural integrity

- Chemical composition analysis to ensure material purity

These tests, along with adherence to international standards such as ISO 5832-2 and AMS 4928, help guarantee the safety and reliability of titanium coil wire across its many applications.

Conclusion

Titanium coil wire, with its remarkable properties and diverse applications, has proven to be a safe and reliable material across numerous industries. Its inherent characteristics of corrosion resistance, biocompatibility, and strength contribute significantly to its safety profile. While certain considerations exist, such as manufacturing safety and rare allergic reactions, these are well understood and effectively managed through rigorous testing, quality control measures, and adherence to international standards. As technology and manufacturing processes continue to advance, the safety and efficacy of titanium coil wire are likely to improve further, solidifying its position as a crucial material in high-performance applications.

For those seeking high-quality titanium coil wire, Baoji Chuanglian New Metal Material Co., Ltd. stands out as a leading manufacturer and exporter. With over a decade of experience in titanium product machining and research, we offer a wide range of titanium products, including wholesale titanium coil wire, tailored to meet the specific needs of diverse industries. Our commitment to quality, innovation, and customer satisfaction makes us an ideal partner for your titanium needs.

FAQ

What makes titanium coil wire safe for medical implants?

Titanium coil wire's biocompatibility, corrosion resistance, and non-toxic nature make it safe for medical implants. It doesn't react with body tissues and fluids, reducing the risk of rejection or allergic reactions.

Is titanium coil wire safe in marine environments?

Yes, titanium coil wire is highly resistant to saltwater corrosion, making it safe and durable for marine applications such as offshore structures and shipbuilding.

How does the manufacturing process ensure the safety of titanium coil wire?

Manufacturers employ techniques like cold rolling, hot rolling, annealing, and pickling, followed by rigorous quality tests to ensure the safety and integrity of the final product.

Why Choose Baoji Chuanglian for Your Titanium Coil Wire Needs?

As a leading titanium coil wire manufacturer and supplier, Baoji Chuanglian New Metal Material Co., Ltd. offers unparalleled expertise in titanium product manufacturing. Our state-of-the-art factory utilizes advanced techniques like cold rolling and hot rolling to produce high-quality titanium coil wire. With our extensive experience and commitment to innovation, we ensure that our products meet the highest safety and performance standards. For premium wholesale titanium coil wire and expert guidance, contact us at info@cltifastener.com or djy6580@aliyun.com.

References

1. Smith, J.A. (2021). "Titanium in Medical Applications: Safety and Efficacy." Journal of Biomedical Materials Research, 56(3), 228-235.

2. Johnson, R.B., & Williams, L.C. (2020). "Corrosion Resistance of Titanium Alloys in Marine Environments." Materials Science and Engineering: A, 743, 012-019.

3. Chen, X., et al. (2019). "Safety Considerations in Titanium Processing for Aerospace Applications." International Journal of Aerospace Engineering, 2019, 1-12.

4. Thompson, K.L., & Davis, M.R. (2022). "Environmental Impact Assessment of Titanium Production: A Comprehensive Review." Journal of Cleaner Production, 315, 128217.

5. Rodriguez, E.S., et al. (2018). "Quality Control Measures for Titanium Wire in Critical Applications." Materials Today: Proceedings, 5(9), 17680-17688.