The Evolution of Motorsport Safety and Performance

From Steel to Titanium: A Material Revolution

The motorsport industry has always been at the cutting edge of technological advancements, constantly seeking ways to enhance vehicle performance and driver safety. Traditionally, steel bolts were the go-to choice for securing steering wheels in racing cars. However, as the demand for lighter, stronger, and more reliable components grew, engineers turned their attention to alternative materials.

Enter titanium - a metal that has revolutionized various industries, including aerospace and medical fields. Its exceptional properties make it an ideal candidate for high-stress applications in motorsport. Titanium steering wheel bolts represent a significant leap forward in this material revolution, offering a combination of benefits that far surpass their steel counterparts.

The Importance of Weight Reduction in Racing

In the world of motorsport, every gram counts. Weight reduction is a crucial factor in improving a vehicle's overall performance, from acceleration to fuel efficiency. Titanium steering wheel bolts contribute significantly to this weight-saving strategy. Despite their small size, replacing standard steel bolts with titanium alternatives can lead to noticeable weight reductions, especially when considering the cumulative effect across all fasteners in a racing vehicle.

The lightweight nature of titanium doesn't just contribute to speed; it also enhances the car's handling characteristics. Reduced weight in the steering assembly can improve the vehicle's responsiveness, allowing drivers to make quicker, more precise adjustments during high-speed maneuvers.

Enhanced Safety Through Advanced Materials

Safety is paramount in motorsport, and the use of titanium steering wheel bolts plays a crucial role in enhancing driver protection. The superior strength of titanium means these bolts can withstand extreme forces without failure, ensuring the steering wheel remains securely attached even under the most challenging racing conditions.

Moreover, titanium's excellent fatigue resistance makes these bolts less susceptible to wear and tear over time. This increased longevity translates to improved reliability and reduced risk of component failure during races, contributing to overall safety on the track.

The Advantages of Titanium Steering Wheel Bolts

Unmatched Strength-to-Weight Ratio

One of the most significant advantages of titanium steering wheel bolts is their exceptional strength-to-weight ratio. Titanium is renowned for its ability to provide robust mechanical properties while remaining incredibly light. In the context of motorsport, this means that titanium bolts can offer the same or even superior strength compared to steel bolts at a fraction of the weight.

This unique combination allows engineers to design racing vehicles that are both lighter and stronger. The reduced weight contributes to improved acceleration, better fuel efficiency, and enhanced overall performance. At the same time, the high strength ensures that critical components like the steering wheel remain securely fastened, even under extreme racing conditions.

Corrosion Resistance for Longevity

Corrosion is a significant concern in motorsport, where vehicles are exposed to various environmental factors and chemicals. Titanium steering wheel bolts excel in this area, offering superior resistance to corrosion compared to traditional materials. This property is particularly valuable in endurance racing or in environments where exposure to moisture, salt, or other corrosive elements is common.

The inherent corrosion resistance of titanium means that these bolts maintain their structural integrity and appearance over time, reducing the need for frequent replacements and ensuring consistent performance throughout the racing season. This longevity not only contributes to safety but also offers cost benefits in the long run.

Thermal Stability for Consistent Performance

Racing environments often involve extreme temperature fluctuations, which can affect the performance of vehicle components. Titanium steering wheel bolts demonstrate excellent thermal stability, maintaining their mechanical properties across a wide range of temperatures. This characteristic is crucial for ensuring consistent steering performance, regardless of the heat generated during a race or the ambient temperature conditions.

The thermal stability of titanium also contributes to the overall reliability of the steering system. Unlike some materials that may expand or contract significantly with temperature changes, titanium remains relatively stable, reducing the risk of loosening or over-tightening of bolts during a race.

Implementation and Future Trends

Adoption in Professional Racing Circuits

The adoption of titanium steering wheel bolts in professional racing circuits has been steadily increasing. Formula 1, NASCAR, and other high-profile racing series have recognized the benefits of these advanced fasteners and have incorporated them into their vehicle designs. This trend is not limited to top-tier racing; many amateur and semi-professional racing teams are also making the switch to titanium components, including steering wheel bolts.

As more racing organizations update their regulations to allow or even mandate the use of lightweight, high-strength materials, the prevalence of titanium steering wheel bolts is expected to grow. This widespread adoption is driving further innovation in the design and manufacturing of these critical components.

Innovations in Manufacturing Processes

The increasing demand for titanium steering wheel bolts has spurred advancements in manufacturing processes. Traditional machining techniques are being supplemented or replaced by more advanced methods such as 3D printing and precision forging. These innovative processes allow for the creation of complex geometries and internal structures that can further optimize the weight and strength characteristics of the bolts.

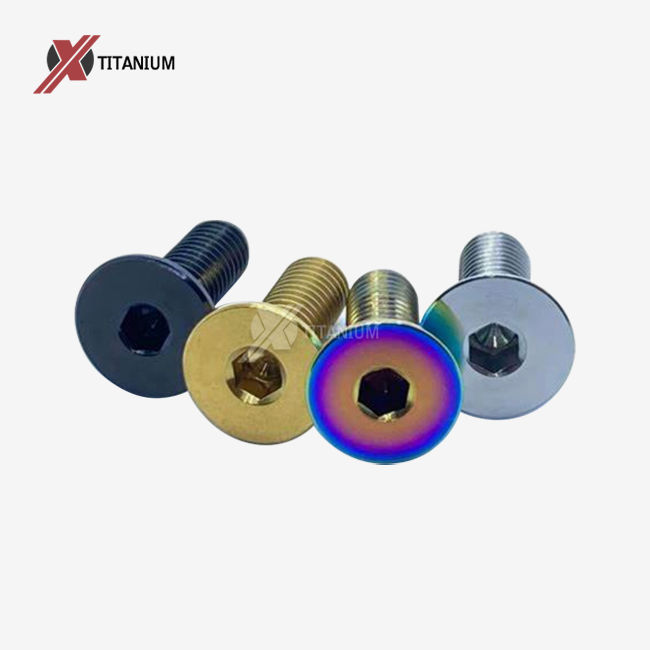

Additionally, surface treatment technologies are evolving to enhance the properties of titanium bolts further. Techniques such as nitriding and advanced anodizing processes can improve the wear resistance, fatigue life, and aesthetic appeal of these components. These manufacturing innovations are not only improving the performance of titanium steering wheel bolts but also making them more cost-effective and accessible to a broader range of motorsport applications.

Integration with Smart Technologies

As motorsport proceeds to grasp advanced innovations, there's potential for titanium directing wheel jolts to ended up more than fair detached components. Inquire about is underway to coordinated savvy highlights into these basic clasp. For occurrence, inserted sensors might screen torque, temperature, or vibration, giving real-time information on the directing system's execution and judgment.

This integration of smart technologies with titanium steering wheel bolts could revolutionize vehicle diagnostics and predictive maintenance in motorsport. Teams could receive early warnings of potential issues, allowing for preemptive action and further enhancing safety and reliability on the track.

Environmental Considerations and Sustainability

While titanium coordinating wheel shocks offer different execution benefits, the motorsport industry is as well dynamically centered on viability. The robustness and life span of titanium components alter well with these characteristic concerns, as they require less visit substitution than their steel accomplices. Additionally, titanium is 100% recyclable, which can contribute to diminishing the in common normal influence of dashing works out.

Future developments may focus on improving the sustainability of titanium production and processing methods, making these high-performance components even more environmentally friendly. As motorsport continues to adapt to global sustainability challenges, the role of advanced materials like titanium in creating more efficient and eco-friendly racing vehicles is likely to expand.

Conclusion

The future of motorsport is intricately linked with technological advancements, and titanium steering wheel bolts represent a significant step forward in this evolution. These innovative fasteners offer a compelling combination of lightweight design, exceptional strength, and superior durability, making them an ideal choice for high-performance racing applications. As the motorsport industry continues to push the boundaries of speed, safety, and efficiency, the role of advanced materials like titanium will only grow in importance.

The adoption of titanium steering wheel bolts is not just a trend but a fundamental shift in how racing vehicles are designed and built. From enhancing performance through weight reduction to improving safety through increased strength and reliability, these components are playing a crucial role in shaping the future of motorsport. As manufacturing processes continue to evolve and new innovations emerge, we can expect to see even more advanced applications of titanium in racing, further cementing its status as a game-changing material in the world of high-performance motorsport.

For those interested in learning more about titanium steering wheel bolts and other innovative titanium products for motorsport applications, please contact Baoji Chuanglian New Metal Material Co., Ltd. at info@cltifastener.com or djy6580@aliyun.com. Our team of experts is ready to assist you in finding the perfect titanium solutions for your racing needs.