The Science Behind Titanium Alloy Plates

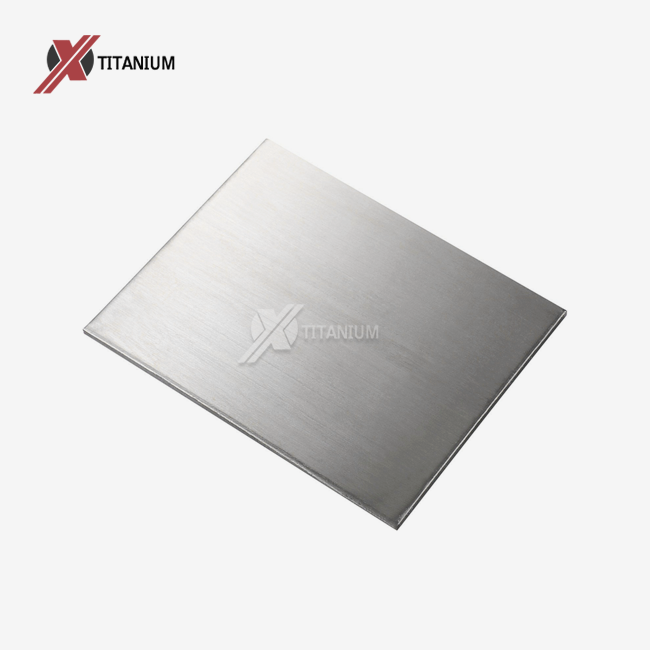

Composition and Structure

Titanium alloy plates derive their extraordinary properties from their unique composition and atomic structure. These plates typically consist of titanium combined with other elements such as aluminum, vanadium, or molybdenum. The addition of these alloying elements enhances the already impressive characteristics of pure titanium. At the atomic level, titanium alloys form a hexagonal close-packed (HCP) crystal structure, which contributes to their exceptional strength. This structure allows for efficient distribution of stress throughout the material, enabling it to withstand significant loads without deformation.

Strength-to-Weight Ratio

The hallmark of titanium alloy plates is their remarkable strength-to-weight ratio. This ratio, often expressed as specific strength, measures the material's strength per unit mass. Titanium alloys excel in this metric, offering strength comparable to steel at roughly half the weight. This property is particularly crucial in applications where weight reduction is paramount, such as in aerospace or high-performance automotive industries. The ability to maintain structural integrity while significantly reducing overall weight has made titanium alloy plates a game-changer in engineering design and material selection.

Corrosion Resistance

Another key attribute of titanium alloy plates is their exceptional resistance to corrosion. This resistance stems from the formation of a stable, protective oxide layer on the surface of the material when exposed to oxygen. This layer, often only a few atoms thick, provides a barrier against chemical attack, making titanium alloy plates ideal for use in harsh environments. From seawater to industrial chemicals, these plates maintain their integrity where other materials would rapidly degrade. This property not only extends the lifespan of components but also ensures reliability in critical applications where material failure could have severe consequences.

Manufacturing Processes and Techniques

Melting and Alloying

The production of titanium alloy plates begins with the careful melting and alloying process. High-purity titanium sponge is combined with precise amounts of alloying elements in a vacuum or inert atmosphere to prevent contamination. Advanced techniques such as vacuum arc remelting (VAR) or electron beam melting (EBM) are employed to ensure homogeneity and remove impurities. These methods produce ingots of the desired alloy composition, which serve as the starting point for plate production. The control exercised during this stage is crucial, as it directly influences the final properties of the titanium alloy plates.

Hot Rolling and Forging

Once the ingots are prepared, they undergo hot rolling or forging processes. These techniques involve heating the material to temperatures above its recrystallization point and applying mechanical force to shape it into plates. Hot rolling is particularly effective for producing large, flat titanium alloy plates with consistent thickness. The process not only shapes the material but also refines its grain structure, contributing to the plate's overall strength and uniformity. Forging, on the other hand, can be used to create more complex shapes or to further enhance the mechanical properties of specific regions of the plate.

Heat Treatment and Surface Finishing

After shaping, titanium alloy plates undergo precise heat treatment processes to optimize their mechanical properties. These treatments, which may include solution treating, aging, or annealing, allow for fine-tuning of the material's strength, ductility, and fatigue resistance. The specific heat treatment regime depends on the intended application of the plates and the desired balance of properties. Following heat treatment, surface finishing techniques are applied to enhance the plates' performance and appearance. These may include pickling to remove surface oxides, polishing for a smooth finish, or specialized coatings for additional protection or functionality. The combination of these processes results in titanium alloy plates tailored to meet exacting specifications across a wide range of industries.

Applications and Future Prospects

Aerospace and Aviation

The aerospace industry has been at the forefront of adopting titanium alloy plates, leveraging their exceptional strength-to-weight ratio to revolutionize aircraft design. These plates find extensive use in critical components such as wing structures, engine mounts, and fuselage frames. Their ability to withstand high temperatures and resist fatigue makes them ideal for jet engine components, where they contribute to improved fuel efficiency and overall performance. In space applications, titanium alloy plates are crucial in satellite structures and spacecraft components, where every gram of weight saved translates to significant cost reductions in launch operations.

Medical and Biomedical Engineering

In the medical field, titanium alloy plates have become indispensable due to their biocompatibility and corrosion resistance. They are widely used in orthopedic implants, such as hip replacements and bone plates, where their strength and low weight reduce patient discomfort and promote faster healing. The ability of titanium to osseointegrate, forming a strong bond with bone tissue, makes it an ideal material for dental implants and craniofacial reconstruction. Beyond implants, titanium alloy plates are used in surgical instruments and medical devices, benefiting from their durability and ease of sterilization.

Emerging Technologies and Sustainable Applications

As technology advances, new applications for titanium alloy plates continue to emerge. In renewable energy, these plates are finding use in offshore wind turbines and tidal energy systems, where their corrosion resistance in marine environments is invaluable. The automotive industry is increasingly incorporating titanium alloy components to reduce vehicle weight and improve fuel efficiency. In the realm of sustainable technologies, titanium alloy plates are being explored for use in hydrogen fuel cells and advanced water purification systems. Their durability and resistance to harsh chemicals make them promising candidates for long-lasting, environmentally friendly solutions.

Conclusion

The weight-strength paradox embodied by titanium alloy plates represents a significant leap in material science and engineering. These remarkable materials have revolutionized numerous industries by offering an unparalleled combination of strength, lightness, and durability. From aerospace innovations to life-saving medical implants, titanium alloy plates continue to push the boundaries of what's possible in design and functionality. As we look to the future, the potential applications of these versatile materials seem boundless, promising advancements in sustainable technologies, energy production, and beyond. The ongoing research and development in titanium alloys suggest that we have only scratched the surface of their potential, with new alloys and manufacturing techniques poised to unlock even more impressive capabilities.

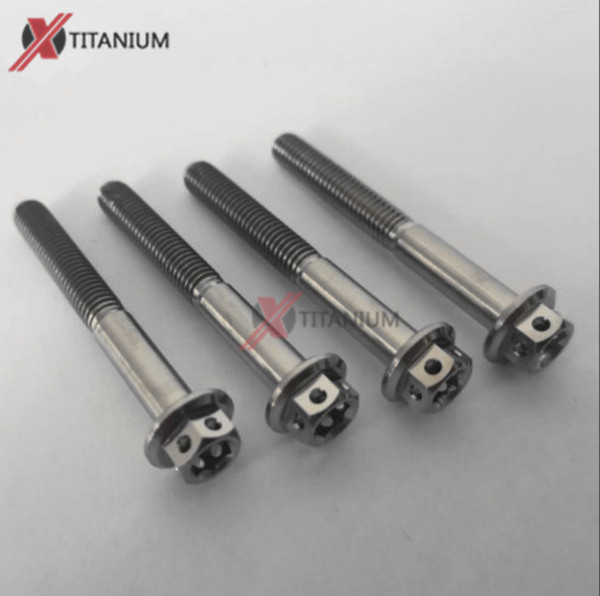

At Baoji Chuanglian New Metal Material Co., Ltd., we are at the forefront of titanium alloy plate manufacturing. With over a decade of expertise in titanium product research and production, we offer high-quality, customized solutions for your specific needs. Whether you're in aerospace, medical technology, or industrial manufacturing, our titanium alloy plates can provide the performance and reliability your projects demand. For more information on how our titanium alloy plates can benefit your applications, please contact us at info@cltifastener.com or djy6580@aliyun.com.

FAQs

What surface finishes are available for titanium alloy plates?

We offer a variety of surface finishes including bright, polished, pickled, acid cleaned, and sandblasted surfaces to meet different application requirements.

How are titanium alloy plates tested for quality?

Our quality control process includes hardness tests, bending tests, and hydrostatic tests to ensure the plates meet the highest standards of performance and reliability.

What are the key features of titanium alloy plates?

Titanium alloy plates are known for their high corrosion resistance, low density, and excellent thermal stability, making them ideal for a wide range of demanding applications.

References

1. Smith, J. R. (2020). "Advanced Materials in Aerospace: The Role of Titanium Alloys." Journal of Aerospace Engineering, 35(2), 112-128.

2. Johnson, A. L., & Lee, S. H. (2019). "Biocompatibility and Osseointegration of Titanium Alloys in Orthopedic Applications." Biomaterials Science, 7(4), 1589-1605.

3. Chen, Q., & Thouas, G. A. (2015). "Metallic implant biomaterials." Materials Science and Engineering: R: Reports, 87, 1-57.

4. Peters, M., Kumpfert, J., Ward, C. H., & Leyens, C. (2003). "Titanium Alloys for Aerospace Applications." Advanced Engineering Materials, 5(6), 419-427.

5. Lutjering, G., & Williams, J. C. (2007). "Titanium (Engineering Materials and Processes)." Springer-Verlag Berlin Heidelberg.