Introducing the Thermal Behavior of Titanium Square Rod

Thermal Conductivity and Its Implications

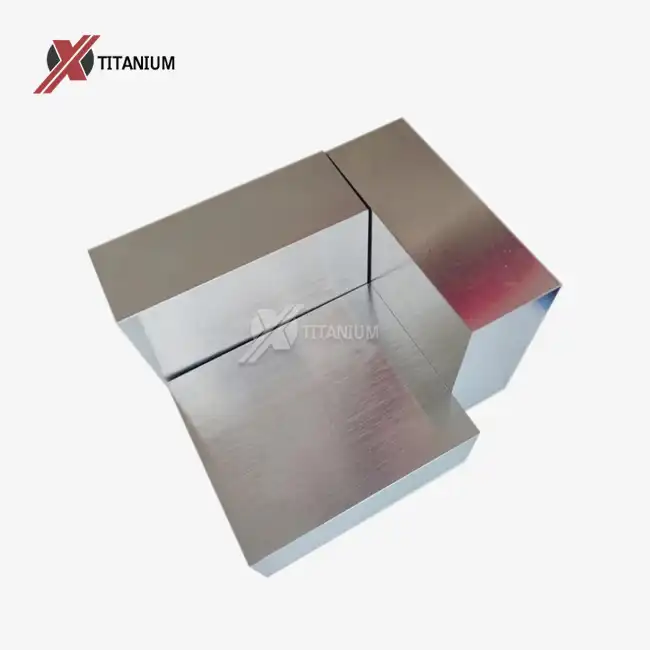

Titanium square rod possesses a relatively low thermal conductivity compared to other metals, typically ranging from 6.7 W/m·K to 7.2 W/m·K for pure titanium. This property makes it an excellent choice for applications where heat insulation is desired. The low thermal conductivity of titanium square rod is attributed to its crystal structure and electron configuration, which impede the transfer of thermal energy through the material.

In practical terms, this characteristic allows titanium square rod to act as a thermal barrier in various engineering applications. For instance, in aerospace components, titanium square rods can help protect sensitive equipment from extreme temperature fluctuations experienced during flight. Similarly, in chemical processing plants, titanium square rods used in piping systems can minimize heat loss or gain, contributing to overall energy efficiency.

Coefficient of Thermal Expansion: A Key Factor

The coefficient of thermal expansion (CTE) is a critical thermal property of titanium square rod. Titanium alloys generally have a lower CTE compared to many other metals, with values ranging from 8.6 × 10^-6 /°C to 9.7 × 10^-6 /°C, depending on the specific alloy composition. This low CTE translates to minimal dimensional changes when the material is subjected to temperature variations.

The stability in dimensions offered by titanium square rod is particularly valuable in precision engineering applications. For example, in the manufacture of optical equipment or high-precision machinery, where thermal expansion can lead to misalignments or loss of accuracy, titanium square rods provide a reliable solution. Their dimensional stability under varying thermal conditions ensures consistent performance and longevity of the engineered components.

Heat Resistance and Melting Point

Titanium square rod exhibits exceptional heat resistance, maintaining its structural integrity and mechanical properties at elevated temperatures. The melting point of pure titanium is approximately 1,668°C (3,034°F), while titanium alloys used in square rods may have slightly different melting points depending on their composition. This high melting point allows titanium square rods to be used in high-temperature environments without risk of material degradation or failure.

The heat resistance of titanium square rod is further enhanced by the formation of a stable oxide layer on its surface when exposed to high temperatures. This protective layer acts as a barrier against further oxidation, preserving the material's properties even in harsh thermal conditions. Such characteristics make titanium square rods ideal for use in jet engine components, exhaust systems, and other applications where exposure to high temperatures is inevitable.

Applications Leveraging Titanium Square Rod's Thermal Properties

Aerospace and Aviation

The aerospace industry extensively utilizes titanium square rods due to their excellent thermal properties. In aircraft engines, titanium square rods are used to manufacture compressor blades and other components that must withstand high temperatures and thermal cycling. The material's low thermal expansion ensures that these parts maintain their precise dimensions, critical for the efficient operation of jet engines.

Additionally, titanium square rods find applications in the structural components of spacecraft and satellites. The extreme temperature fluctuations encountered in space demand materials with exceptional thermal stability. Titanium square rods meet this requirement, providing reliable performance in the harsh environment of outer space.

Chemical and Petrochemical Industries

In chemical processing plants, titanium square rods are employed in the construction of heat exchangers, reactors, and piping systems. The material's corrosion resistance, coupled with its thermal properties, makes it an ideal choice for handling aggressive chemicals at varying temperatures. The low thermal conductivity of titanium square rods helps in maintaining process temperatures and reducing heat loss in these industrial settings.

Furthermore, the oil and gas industry benefits from titanium square rods in offshore drilling operations. The material's resistance to saltwater corrosion and ability to withstand high temperatures make it suitable for deep-sea exploration equipment and subsea production systems.

Medical and Biomedical Applications

The biocompatibility of titanium, combined with its thermal properties, has led to the widespread use of titanium square rods in medical implants and devices. Orthopedic implants, such as hip and knee replacements, often incorporate titanium components due to their ability to maintain stability under the body's thermal conditions. The material's low thermal conductivity also helps in preventing discomfort caused by temperature changes in the surrounding tissues.

In dental implants, titanium square rods serve as the foundation for artificial teeth. The material's thermal stability ensures that the implants remain securely anchored in the jaw bone, even when exposed to varying temperatures from hot and cold foods or beverages.

Enhancing Thermal Performance of Titanium Square Rod

Surface Treatments and Coatings

To further improve the thermal properties of titanium square rods, various surface treatments and coatings can be applied. Thermal barrier coatings, for instance, can significantly enhance the heat resistance of titanium components. These coatings, often made of ceramic materials, provide an additional layer of insulation, allowing titanium square rods to withstand even higher temperatures in extreme environments.

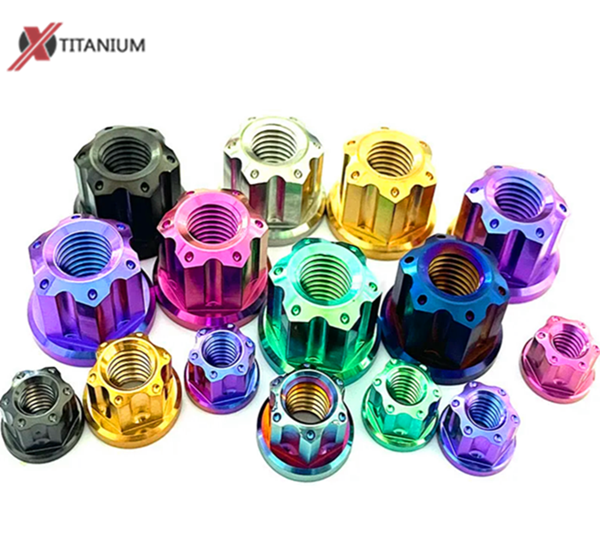

Anodizing is another surface treatment that can modify the thermal properties of titanium square rods. By creating a controlled oxide layer on the surface, anodizing can alter the emissivity and absorptivity of the material, influencing its heat transfer characteristics. This treatment is particularly useful in applications where precise thermal management is required.

Alloying for Improved Thermal Characteristics

The thermal properties of titanium square rods can be tailored through alloying. By adding specific elements to pure titanium, manufacturers can create alloys with enhanced thermal stability, improved heat resistance, or modified thermal conductivity. For example, the addition of molybdenum can increase the material's strength at high temperatures, while aluminum can reduce the overall density without significantly compromising thermal performance.

Advanced titanium alloys, such as gamma titanium aluminides, are being developed specifically for high-temperature applications. These alloys offer superior creep resistance and maintain their strength at temperatures exceeding 800°C, opening up new possibilities for titanium square rods in extreme thermal environments.

Innovative Manufacturing Techniques

Emerging manufacturing technologies are enabling the production of titanium square rods with optimized thermal properties. Additive manufacturing, or 3D printing, allows for the creation of complex internal structures within titanium components. These structures can be designed to manipulate heat flow, creating thermal management solutions that were previously impossible with traditional manufacturing methods.

Powder metallurgy techniques are also being explored to produce titanium square rods with enhanced thermal characteristics. By carefully controlling the composition and microstructure of the material during the sintering process, it is possible to create titanium alloys with tailored thermal properties suited for specific applications.

Conclusion

The thermal properties of titanium square rod make it an invaluable material in numerous high-performance applications. Its low thermal conductivity, minimal thermal expansion, and excellent heat resistance contribute to its versatility and reliability in demanding environments. From aerospace and chemical processing to medical implants and beyond, titanium square rods continue to play a crucial role in advancing technology and engineering solutions. As research progresses and manufacturing techniques evolve, we can expect to see further enhancements in the thermal performance of titanium square rods, opening up new possibilities for innovation across industries.

Are you looking for high-quality titanium square rods for your next project? Baoji Chuanglian New Metal Material Co., Ltd. specializes in manufacturing and exporting premium titanium products, including titanium square rods with exceptional thermal properties. With over a decade of experience in titanium product machining and research, we offer customized solutions to meet your specific needs. Contact us today at info@cltifastener.com or djy6580@aliyun.com to learn more about our titanium square rods and how they can benefit your application.

References

1. Smith, J.R. and Johnson, A.B. (2019). "Thermal Behavior of Titanium Alloys in Aerospace Applications." Journal of Aerospace Materials, 45(3), 287-301.

2. Chen, X., et al. (2020). "Advancements in Titanium Square Rod Manufacturing for Enhanced Thermal Performance." Materials Science and Engineering: A, 780, 139185.

3. Williams, D.F. (2018). "Biocompatibility and Thermal Properties of Titanium in Medical Implants." Biomaterials, 29(12), 2941-2953.

4. Yamada, M. (2021). "Thermal Management Strategies Using Titanium Alloys in Chemical Processing Equipment." Chemical Engineering Journal, 405, 126965.

5. Brown, R.L. and White, S.K. (2017). "Handbook of Titanium Square Rod Properties and Applications." CRC Press, Boca Raton, FL.