The Advantages of Titanium in Automotive Applications

Unrivaled Strength-to-Weight Ratio

Titanium steering wheel bolts exemplify the material's exceptional strength-to-weight ratio. This unique property allows for the creation of fasteners that are significantly lighter than their steel counterparts while maintaining, and often exceeding, the necessary structural integrity. In the realm of high-performance automobiles and motorsports, where every gram counts, the weight reduction achieved through the use of titanium bolts can translate into measurable improvements in acceleration, handling, and overall vehicle dynamics.

The density of titanium is approximately 60% that of steel, yet it offers comparable strength. This means that titanium steering wheel bolts can be designed to withstand the same forces as steel bolts while weighing considerably less. The reduced weight at the steering column can contribute to a more responsive steering feel, allowing drivers to experience enhanced feedback and control during high-speed maneuvers or precise cornering.

Superior Corrosion Resistance

Another significant advantage of titanium steering wheel bolts is their innate resistance to corrosion. Unlike steel, which is prone to rust and degradation when exposed to moisture and harsh environmental conditions, titanium forms a protective oxide layer on its surface. This natural barrier shields the metal from chemical attacks and prevents the formation of rust, ensuring that the bolts maintain their structural integrity and aesthetic appeal over time.

The corrosion-resistant nature of titanium is particularly beneficial in automotive applications where components may be exposed to road salt, humidity, and other corrosive elements. Titanium steering wheel bolts can withstand these challenges without the need for additional protective coatings, reducing maintenance requirements and extending the lifespan of the fasteners. This durability is especially valuable in racing environments, where reliability and consistent performance are paramount.

Aesthetic Appeal and Customization Options

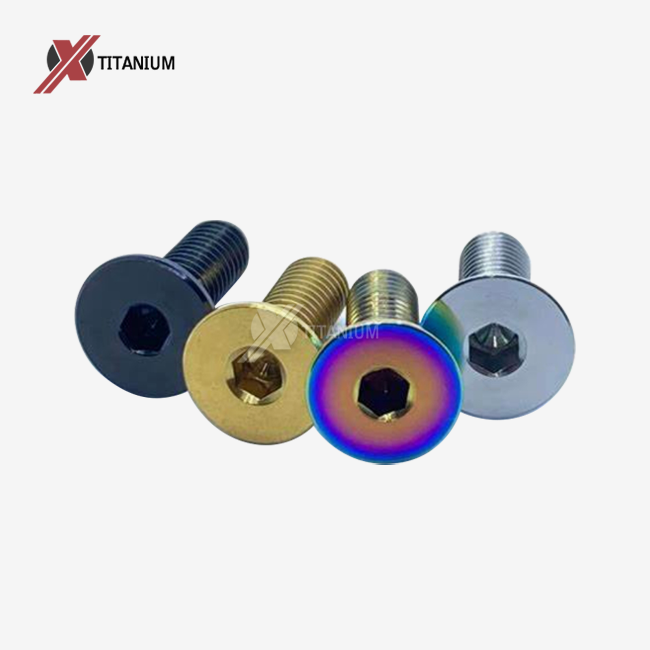

Beyond their functional benefits, titanium steering wheel bolts offer aesthetic advantages that appeal to automotive enthusiasts and designers alike. The natural luster of titanium provides a sophisticated, high-tech appearance that complements modern vehicle interiors. Moreover, titanium can be anodized to produce a range of vibrant colors without compromising its structural properties.

This versatility in finishing options allows for seamless integration with various interior design schemes or the creation of striking visual accents. From subtle, brushed finishes to bold, anodized hues, titanium steering wheel bolts can be customized to enhance the overall look of a vehicle's cockpit while still delivering on their primary function of secure fastening.

Manufacturing Processes and Quality Control

Precision CNC Machining

The production of high-quality titanium steering wheel bolts requires advanced manufacturing techniques to ensure precision and consistency. Computer Numerical Control (CNC) machining stands at the forefront of this process, allowing for the creation of bolts with exact specifications and tight tolerances. This level of precision is crucial for maintaining the integrity of the steering assembly and ensuring optimal performance.

CNC machines are programmed to follow intricate patterns, cutting and shaping titanium alloy stock into the desired bolt form. The process allows for the creation of complex thread patterns and bolt head designs that may be required for specific vehicle models or racing regulations. The ability to maintain consistent quality across production runs is a key advantage of CNC machining, ensuring that each titanium steering wheel bolt meets the exacting standards required for high-performance applications.

Heat Treatment and Surface Finishing

After the initial machining process, titanium steering wheel bolts often undergo heat treatment to enhance their mechanical properties. This process can involve techniques such as solution treating and aging, which alter the microstructure of the titanium alloy to achieve the desired balance of strength, ductility, and fatigue resistance. The specific heat treatment protocol is carefully tailored to the intended application of the bolts, whether for street use or competitive racing.

Surface finishing is another critical step in the manufacturing process. While titanium naturally forms a protective oxide layer, additional treatments can further improve corrosion resistance and aesthetic appeal. Common finishing techniques for titanium steering wheel bolts include:

- Anodizing: An electrochemical process that creates a durable, colored oxide layer on the surface of the titanium.

- Polishing: Mechanical or chemical polishing to achieve a smooth, reflective surface.

- Shot peening: A cold working process that improves fatigue life by inducing compressive stresses on the surface.

Rigorous Quality Control Measures

To ensure that titanium steering wheel bolts meet the highest standards of safety and performance, manufacturers implement stringent quality control measures throughout the production process. These may include:

- Material verification: Testing to confirm the composition and grade of the titanium alloy used.

- Dimensional inspection: Precise measurements to verify that bolts meet specified tolerances.

- Tensile strength testing: Assessing the bolt's ability to withstand tension forces without failure.

- Torque testing: Evaluating the bolt's performance under tightening conditions.

- Fatigue testing: Simulating repeated stress cycles to ensure long-term durability.

- Chemical analysis: Verifying the surface treatment and corrosion resistance properties.

These comprehensive quality control procedures help to maintain the reliability and consistency of titanium steering wheel bolts, providing peace of mind to automotive manufacturers, racing teams, and individual enthusiasts who rely on these critical components.

Applications and Future Trends

Motorsports and High-Performance Vehicles

The primary domain where titanium steering wheel bolts have made a significant impact is in motorsports and high-performance vehicles. In these applications, the reduction in weight offered by titanium components can translate into tangible performance gains. Racing teams meticulously analyze every component for potential weight savings, and steering wheel bolts, though small, contribute to the overall weight reduction strategy.

Equation 1, World Rally Championship (WRC), and perseverance dashing arrangement like Le Mans have all seen the appropriation of titanium latches, counting controlling wheel jolts. The weight investment funds at the controlling column can move forward the vehicle's center of gravity and upgrade the driver's capacity to make speedy, exact controlling inputs. Additionally, the toughness of titanium guarantees that these basic components can withstand the extraordinary strengths and vibrations experienced in high-speed dashing situations.

Luxury and Performance Road Cars

The benefits of titanium coordinating wheel jars are not obliged to the circuit. High-end sports cars and luxury vehicles are dynamically joining titanium components as a stamp of quality and execution. For these vehicles, titanium coordinating wheel jars offer a blend of valuable focuses of intrigued and premium offer. The weight diminishment, though perhaps less essential than in hustling applications, still contributes to in common vehicle stream and fuel capability.

Luxury car manufacturers also appreciate the corrosion resistance and aesthetic versatility of titanium. The ability to anodize titanium bolts in various colors allows for seamless integration with bespoke interior designs, catering to discerning customers who demand both performance and personalization in their vehicles.

Emerging Trends and Future Prospects

As automotive technology continues to evolve, the role of titanium steering wheel bolts and other lightweight components is likely to expand. Several trends point to an increasing adoption of titanium in automotive applications:

- Electric Vehicles (EVs): With the growth of the EV market, weight reduction becomes even more crucial to extend range and improve efficiency. Titanium components, including steering wheel bolts, can contribute to overall weight savings.

- Advanced Manufacturing: Innovations in 3D printing and other additive manufacturing techniques may open up new possibilities for designing and producing titanium automotive components with even greater precision and customization.

- Sustainability: As the automotive industry focuses on sustainability, the long lifespan and recyclability of titanium align well with eco-friendly initiatives.

- Autonomous Vehicles: While the steering wheel's role may change in autonomous vehicles, the need for lightweight, durable fasteners in critical systems will remain relevant.

Conclusion

Titanium steering wheel bolts epitomize the tenacious interest of execution and advancement in the car industry. By advertising an ideal adjust of quality and weight, these apparently little components play a vital part in upgrading vehicle elements, security, and driver involvement. From the high-stakes world of motorsports to the refined extravagance of premium street cars, titanium jolts proceed to demonstrate their worth as vital components in advanced car designing.

As we look to the future, the applications for titanium in automotive design are likely to expand, driven by the ongoing quest for efficiency, performance, and sustainability. The unique properties of titanium steering wheel bolts – their strength, lightness, corrosion resistance, and aesthetic appeal – position them at the forefront of automotive innovation, ready to meet the challenges of tomorrow's vehicles.

For more information about titanium steering wheel bolts and other high-performance titanium components, please contact Baoji Chuanglian New Metal Material Co., Ltd. at info@cltifastener.com or djy6580@aliyun.com. Our team of experts is ready to assist you in finding the perfect titanium solutions for your automotive needs.