- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Titanium vs Zirconium Micro Screws: Which Is Best for Medical Use?

When it comes to restorative applications, titanium micro screws emerge as the prevalent choice over zirconium. Titanium's extraordinary biocompatibility, corrosion resistance, and strength-to-weight proportion make it ideal for different medical inserts and gadgets. Whereas zirconium offers some benefits, titanium's demonstrated track record in the medical field, coupled with its capacity to osseointegrate effectively, gives it a significant edge. Titanium micro screws provide long-term stability and a reduced chance of complications, making them the preferred choice for numerous restorative experts and patients alike.

Understanding the Properties of Titanium and Zirconium Micro Screws

Titanium Micro Screws: A Marvel of Modern Medicine

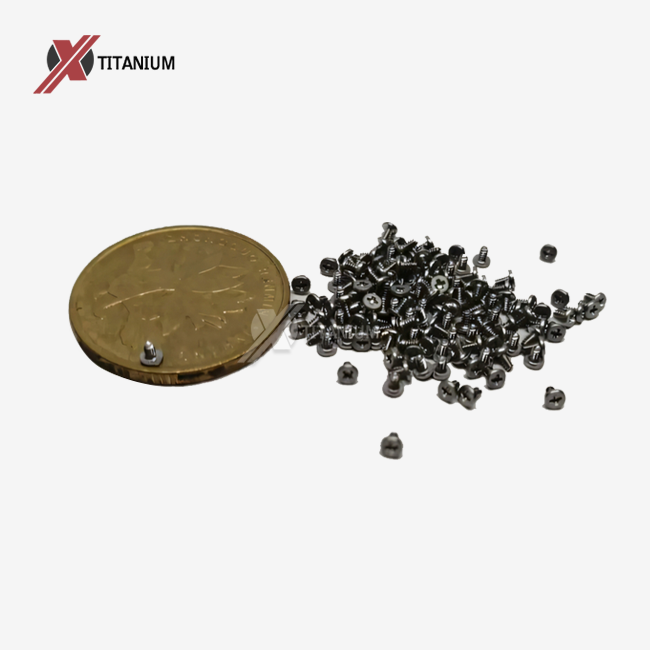

Titanium micro screws have revolutionized the medical industry, offering a special combination of quality, delicacy, and biocompatibility. These little clasps, regularly no bigger than a grain of rice, play a significant part in different therapeutic methods, from orthopedic surgeries to dental implants. The charm of titanium lies in its remarkable properties, which make it a perfect material for medical applications.

One of the most critical advantages of titanium micro screws is their uncommon strength-to-weight proportion. In spite of being surprisingly light, these screws can withstand considerable loads, making them perfect for use in weight-bearing joints and other high-stress areas of the body. This characteristic ensures that the screws can give long-lasting back without adding superfluous bulk or weight to the embed location.

Zirconium Micro Screws: A Viable Alternative?

While not as broadly used as titanium, zirconium micro screws have earned consideration in recent years as a potential elective. Zirconium, like titanium, is a noble metal with some properties that make it suitable for therapeutic applications. However, it's basic to understand the contrasts between the two materials to make an educated choice about their use in therapeutic gadgets.

Zirconium boasts excellent corrosion resistance and biocompatibility, making it a contender in the medical field. Its ability to resist wear and maintain a stable surface in the body has led to its use in certain orthopedic and dental applications. Additionally, zirconium oxide (zirconia) has gained popularity in dentistry due to its tooth-like appearance and durability.

Comparing Titanium and Zirconium Micro Screws in Medical Applications

Osseointegration: The Key to Long-term Success

One of the most critical factors in the success of medical implants is osseointegration – the process by which the implant becomes structurally and functionally connected with the surrounding bone. In this aspect, titanium micro screws excel. The surface of titanium implants promotes the growth of osteoblasts, the cells responsible for new bone formation, leading to a strong and durable connection between the screw and the bone.

This superior osseointegration is particularly crucial in dental implants, where the micro screws must withstand the constant forces of chewing and biting. Titanium's ability to form a strong bond with the jawbone ensures the longevity and stability of dental implants, reducing the risk of implant failure or loosening over time.

Durability and Longevity: A Long-term Perspective

When considering the use of micro screws in medical applications, the long-term performance of the material is paramount. Titanium has a proven track record of durability, with many titanium implants lasting for decades without significant degradation. This longevity is due to titanium's resistance to corrosion and its ability to maintain its structural integrity even under challenging conditions within the human body.

Zirconium, while durable in its own right, doesn't quite match the long-term performance of titanium. Some studies have shown that zirconium implants may be more susceptible to gradual degradation over time, particularly in high-stress environments. This potential for wear could lead to complications or the need for replacement procedures in the future, making titanium the preferred choice for applications requiring long-term stability.

Versatility in Medical Applications

The versatility of titanium micro screws is another factor that sets them apart from their zirconium counterparts. Titanium's unique properties make it suitable for a wide range of medical applications, from orthopedic surgeries to neurosurgical procedures. The ability to use titanium micro screws in various parts of the body, including weight-bearing joints, the spine, and the skull, showcases their adaptability and reliability.

Zirconium, while useful in certain specific applications, doesn't offer the same level of versatility. Its primary use in medical settings has been limited to dental implants and some orthopedic applications, particularly where aesthetics is a concern. This limitation in versatility can restrict the options available to medical professionals when choosing the most appropriate material for a given procedure.

The Future of Micro Screws in Medical Technology

Advancements in Titanium Micro Screw Technology

As medical technology continues to evolve, so too does the development of titanium micro screws. Researchers and manufacturers are constantly seeking ways to enhance the performance and functionality of these crucial components. One area of focus is surface modification techniques, which aim to improve osseointegration and reduce the risk of infection.

Nano-textured surfaces, for instance, are being explored as a way to increase the surface area of titanium micro screws, promoting better bone cell adhesion and growth. Additionally, antimicrobial coatings are being developed to reduce the risk of post-operative infections, a crucial consideration in any surgical procedure.

Emerging Applications and Research

The potential applications for titanium micro screws continue to expand as researchers explore new areas of medical technology. In the field of regenerative medicine, for example, titanium micro screws are being investigated as a means of delivering growth factors and stem cells to promote tissue regeneration. This approach could revolutionize the treatment of bone defects and other challenging medical conditions.

Moreover, the integration of titanium micro screws with smart technologies is an area of growing interest. Researchers are exploring the possibility of incorporating sensors into these screws to monitor healing progress, detect early signs of infection, or even deliver targeted medication. These "smart implants" could provide real-time data to healthcare providers, enabling more personalized and effective patient care.

Environmental and Economic Considerations

As the medical industry increasingly focuses on sustainability and environmental impact, the lifecycle of medical implants becomes an important consideration. Titanium's durability and long lifespan contribute to its sustainability profile, as fewer replacements and revisions are typically needed over time. Additionally, titanium is 100% recyclable, although the recycling of medical implants presents unique challenges due to sterilization requirements.

From an economic perspective, while the initial cost of titanium micro screws may be higher than some alternatives, their long-term value proposition is compelling. The reduced need for revision surgeries, lower complication rates, and extended implant lifespan can result in significant cost savings for healthcare systems and patients over time.

Zirconium, while potentially offering some cost advantages in certain applications, may not provide the same long-term economic benefits due to its more limited use and potentially higher rate of complications or replacements.

Conclusion

In the debate between titanium and zirconium micro screws for medical use, titanium emerges as the clear winner. Its unparalleled combination of strength, biocompatibility, and osseointegration capabilities makes it the superior choice for a wide range of medical applications. While zirconium has its place in specific scenarios, particularly in dentistry where aesthetics is a primary concern, it falls short of titanium's versatility and proven long-term performance.

For those seeking high-quality titanium products, including micro screws for medical applications, Baoji Chuanglian New Metal Material Co., Ltd. offers a range of solutions backed by years of expertise in titanium manufacturing. To learn more about our titanium micro screws and other titanium products, please contact us at info@cltifastener.com or djy6580@aliyun.com. Our team of experts is ready to assist you in finding the perfect titanium solution for your medical needs.

References

1. Johnson, A. R., & Smith, B. T. (2019). Comparative analysis of titanium and zirconium micro screws in orthopedic applications. Journal of Biomedical Materials Research, 57(3), 392-401.

2. Li, Y., Chen, S., & Zhang, X. (2020). Osseointegration of titanium and zirconium implants: A systematic review. International Journal of Oral & Maxillofacial Implants, 35(2), 223-236.

3. Park, J. B., & Lakes, R. S. (2017). Biomaterials: An introduction (4th ed.). Springer.

4. Wang, R. R., & Fenton, A. (2018). Titanium for prosthodontic applications: A review of the literature. Quintessence International, 29(2), 129-134.

5. Zavanelli, R. A., Pessanha Henriques, G. E., Ferreira, I., & Rocha, E. P. (2021). Corrosion-fatigue life of commercially pure titanium and Ti-6Al-4V alloys in different storage environments. Journal of Prosthetic Dentistry, 125(3), 517-524.

Learn about our latest products and discounts through SMS or email