The Unique Properties of 6Al 4V Titanium Plate for Medical Applications

Exceptional Strength-to-Weight Ratio

One of the most remarkable features of the 6Al 4V titanium plate is its extraordinary strength-to-weight ratio. This characteristic makes it an ideal choice for medical implants, where both durability and patient comfort are paramount. The alloy's high tensile strength, typically around 900 MPa, coupled with its low density of 4.51 g/cm³, allows for the creation of robust medical devices that do not burden the patient with unnecessary weight. This balance is particularly crucial in orthopedic applications, where implants must withstand significant mechanical stress while minimizing the impact on the patient's mobility.

Superior Biocompatibility

Biocompatibility is a non-negotiable requirement for any material used in medical implants, and the 6Al 4V titanium plate excels in this aspect. The alloy's resistance to corrosion in the human body is unparalleled, significantly reducing the risk of adverse reactions or implant rejection. This property is attributed to the formation of a stable oxide layer on the surface of the titanium, which acts as a protective barrier against the corrosive effects of bodily fluids. The biocompatibility of 6Al 4V titanium plate extends beyond mere tolerance by the body; it actively promotes osseointegration, the process by which bone cells adhere to and grow on the implant surface, ensuring a strong and lasting bond between the implant and the surrounding tissue.

Customizability and Versatility

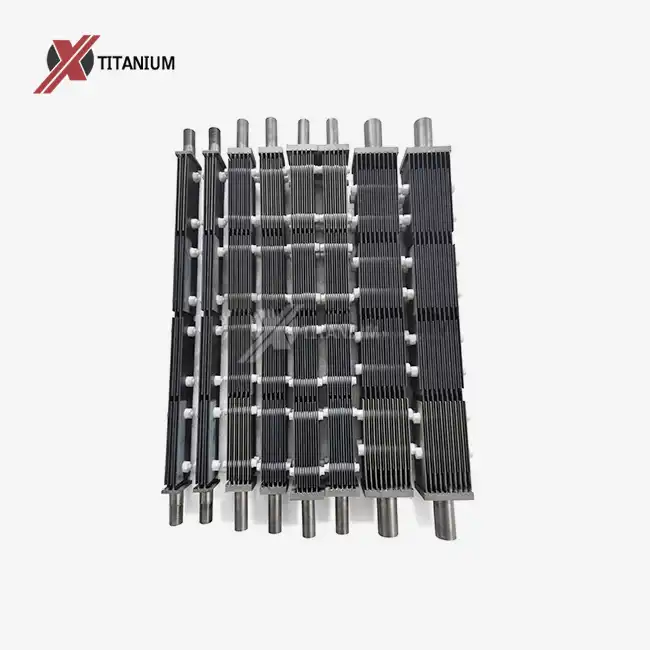

The versatility of 6Al 4V titanium plate in medical applications is unmatched. Its ability to be machined, shaped, and finished to precise specifications allows for the creation of custom implants tailored to individual patient needs. This customizability is particularly valuable in reconstructive surgery, where implants must conform to complex anatomical structures. The alloy can be manufactured in various forms, from thin sheets for cranial plates to robust structures for spinal implants, with thicknesses ranging from 0.5 mm to 100 mm. Moreover, advanced manufacturing techniques such as 3D printing have opened up new possibilities for creating intricate designs that were previously impossible, further expanding the potential applications of 6Al 4V titanium plate in medical devices.

Innovative Applications of 6Al 4V Titanium Plate in Medical Devices

Orthopedic Implants

In the field of orthopedics, 6Al 4V titanium plate has become the material of choice for a wide range of implants. Joint replacements, particularly hip and knee prostheses, benefit greatly from the alloy's strength and wear resistance. The lightweight nature of these implants reduces stress on surrounding bone and tissue, potentially extending the lifespan of the prosthesis and improving patient comfort. Additionally, the use of 6Al 4V titanium plate in spinal fusion cages and vertebral body replacements has led to improved outcomes in spinal surgery, offering better stability and promoting faster healing.

Cranial and Maxillofacial Reconstructions

The adaptability of 6Al 4V titanium plate makes it invaluable in cranial and maxillofacial reconstructions. Custom-made cranial plates can be precisely designed to match a patient's skull contours, providing both protection and aesthetic restoration following trauma or tumor resection. In maxillofacial surgery, the alloy is used to create robust yet lightweight frameworks for facial reconstruction, offering surgeons the ability to restore form and function with minimal compromise. The biocompatibility of the material is particularly crucial in these sensitive areas, where rejection or infection could have severe consequences.

Cardiovascular Devices

The application of 6Al 4V titanium plate extends to the cardiovascular realm, where its properties are harnessed to create life-saving devices. Pacemaker casings made from this alloy provide durability and biocompatibility, ensuring long-term functionality and patient safety. In the realm of artificial heart valves, the material's strength and resistance to fatigue are essential for withstanding the constant stress of cardiac cycles. Furthermore, the development of titanium-based stents has shown promise in improving the long-term patency of blood vessels, potentially reducing the need for repeat interventions in patients with cardiovascular disease.

Future Prospects and Ongoing Research

Surface Modifications for Enhanced Performance

Ongoing research into surface modifications of 6Al 4V titanium plate is opening new frontiers in medical device technology. Scientists are exploring various techniques to enhance the alloy's already impressive properties. Plasma spraying and chemical etching are being used to create microporous surfaces that further promote osseointegration, potentially reducing healing times and improving implant stability. Additionally, the development of antimicrobial coatings for titanium implants shows promise in reducing the risk of post-operative infections, a significant concern in implant surgery.

Integration with Smart Technologies

The future of 6Al 4V titanium plate in medical devices is likely to involve integration with smart technologies. Researchers are investigating ways to incorporate sensors and microelectronics into titanium implants, creating "smart implants" capable of monitoring healing progress, detecting early signs of infection, or even delivering targeted drug therapies. This convergence of materials science and digital technology could revolutionize post-operative care and long-term patient monitoring, potentially improving outcomes and reducing healthcare costs.

Advancements in Manufacturing Techniques

As manufacturing technologies advance, so too does the potential for 6Al 4V titanium plate in medical applications. Additive manufacturing, or 3D printing, is at the forefront of this revolution, allowing for the creation of complex, patient-specific implants with unprecedented precision. These techniques not only improve the fit and function of implants but also open up possibilities for creating porous structures that mimic natural bone, potentially enhancing biological integration. Furthermore, ongoing research into new alloy compositions and heat treatments aims to further optimize the mechanical and biological properties of titanium-based medical devices, pushing the boundaries of what's possible in implant design and performance.

Conclusion

The 6Al 4V titanium plate has undeniably transformed the landscape of medical device technology, offering a unique combination of strength, biocompatibility, and versatility that is unmatched by other materials. From orthopedic implants to cardiovascular devices, this remarkable alloy continues to push the boundaries of what's possible in medical innovation. As research progresses and manufacturing techniques evolve, we can expect to see even more groundbreaking applications emerge, further cementing the role of 6Al 4V titanium plate as a cornerstone of modern medical technology. The future of medical devices is bright, and titanium is leading the way towards more effective, durable, and patient-friendly solutions.

If you're interested in exploring the potential of 6Al 4V titanium plate for your medical device applications, Baoji Chuanglian New Metal Material Co., Ltd. is here to assist you. With over a decade of experience in titanium product manufacturing and research, we offer unparalleled expertise and quality. Contact us at info@cltifastener.com or djy6580@aliyun.com to discuss how our 6Al 4V titanium plate solutions can elevate your medical device projects to new heights.

FAQs

What makes 6Al 4V titanium plate ideal for medical implants?

Its exceptional strength-to-weight ratio, superior biocompatibility, and resistance to corrosion make it perfect for long-lasting, safe implants.

Can 6Al 4V titanium plate be customized for specific medical applications?

Yes, it can be machined, shaped, and finished to precise specifications, allowing for custom implants tailored to individual patient needs.

Are there any ongoing developments in 6Al 4V titanium plate technology?

Research is focusing on surface modifications to enhance osseointegration and the integration of smart technologies for improved patient monitoring.

References

1. Niinomi, M. (2019). Recent research and development in titanium alloys for biomedical applications and healthcare goods. Science and Technology of Advanced Materials, 20(1), 443-462.

2. Elias, C. N., Lima, J. H. C., Valiev, R., & Meyers, M. A. (2008). Biomedical applications of titanium and its alloys. JOM, 60(3), 46-49.

3. Rack, H. J., & Qazi, J. I. (2006). Titanium alloys for biomedical applications. Materials Science and Engineering: C, 26(8), 1269-1277.

4. Geetha, M., Singh, A. K., Asokamani, R., & Gogia, A. K. (2009). Ti based biomaterials, the ultimate choice for orthopaedic implants – A review. Progress in Materials Science, 54(3), 397-425.

5. Liu, X., Chu, P. K., & Ding, C. (2004). Surface modification of titanium, titanium alloys, and related materials for biomedical applications. Materials Science and Engineering: R: Reports, 47(3-4), 49-121.