Unique Properties and Characteristics of Titanium Flat Wire

Exceptional Strength-to-Weight Ratio

Titanium flat wire boasts an impressive strength-to-weight ratio, a characteristic that sets it apart from many other materials. This property makes it particularly valuable in industries where weight reduction is crucial without compromising structural integrity. The aerospace sector, for instance, heavily relies on titanium flat wire for various components due to its ability to withstand high stress while maintaining a low overall weight. This unique combination of strength and lightness contributes to improved fuel efficiency in aircraft and space vehicles.

Moreover, the automotive industry is increasingly turning to titanium flat wire as a solution for reducing vehicle weight while enhancing performance. By incorporating this material into critical components, manufacturers can achieve significant weight savings, leading to improved fuel economy and reduced emissions. The high strength of titanium flat wire also allows for the design of thinner, more compact parts without sacrificing durability, opening up new possibilities in automotive engineering and design.

Superior Corrosion Resistance

One of the most notable advantages of titanium flat wire is its exceptional resistance to corrosion. This property stems from the formation of a stable, protective oxide layer on the surface of the material when exposed to air or moisture. This natural barrier provides titanium flat wire with unparalleled protection against various corrosive environments, including saltwater, acids, and industrial chemicals.

The corrosion resistance of titanium flat wire makes it an ideal choice for marine applications, where exposure to saltwater can rapidly degrade many other materials. Ships, offshore platforms, and underwater equipment benefit greatly from the use of titanium components, ensuring longer service life and reduced maintenance costs. Similarly, in chemical processing plants, where harsh chemicals are commonplace, the product offers a reliable solution for constructing equipment and components that can withstand aggressive corrosive agents.

Biocompatibility and Medical Applications

Titanium flat wire's biocompatibility is another significant advantage that sets it apart from many other materials. The human body readily accepts titanium, making it an excellent choice for medical implants, surgical instruments, and prosthetics. This biocompatibility is due to the material's resistance to corrosion by bodily fluids and its non-toxic nature, which minimizes the risk of adverse reactions or rejection by the body.

In the field of dentistry, it is widely used for dental implants and orthodontic applications. Its strength and durability ensure long-lasting results, while its biocompatibility promotes osseointegration - the process by which bone cells attach directly to the titanium surface. This property is crucial for the success and longevity of dental implants. Additionally, titanium flat wire's flexibility and shape memory make it ideal for creating advanced orthodontic appliances that provide more comfortable and effective treatments.

Manufacturing Processes and Versatility of Titanium Flat Wire

Advanced Production Techniques

The manufacturing of titanium flat wire involves sophisticated processes that contribute to its exceptional properties. Cold rolling, hot rolling, annealing, and pickling are among the techniques employed to produce high-quality product. These processes allow for precise control over the material's dimensions, mechanical properties, and surface finish, ensuring that the final product meets specific industry requirements.

Cold rolling, for instance, enhances the strength and hardness of titanium flat wire while maintaining tight dimensional tolerances. This process is particularly useful for applications requiring high precision and consistency. Hot rolling, on the other hand, is employed to produce larger quantities of titanium flat wire with improved ductility. Annealing is utilized to relieve internal stresses and optimize the material's mechanical properties, while pickling ensures a clean, oxide-free surface, crucial for many applications.

Customizable Surface Finishes

Titanium flat wire can be produced with various surface finishes to suit different applications. Options include bright, polished, pickled, acid-cleaned, and sandblasted surfaces. Each finish imparts specific characteristics to the wire, enhancing its performance in particular environments or applications. For example, a polished finish provides excellent smoothness and reduces friction, making it ideal for medical implants or moving parts in machinery.

The ability to customize surface finishes extends the versatility of titanium flat wire across industries. A sandblasted finish, for instance, increases surface area and improves adhesion properties, beneficial in applications requiring bonding or coating. Acid cleaning and pickling processes remove surface impurities and create a passive layer, further enhancing the material's corrosion resistance. This flexibility in surface treatment allows manufacturers to tailor titanium flat wire to meet the exact requirements of diverse applications.

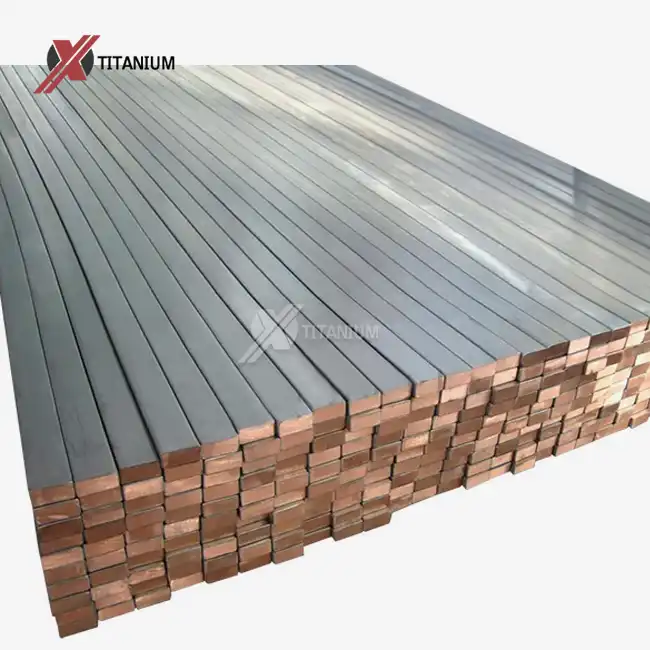

Wide Range of Sizes and Grades

Titanium flat wire is available in an extensive range of sizes and grades, catering to diverse industry needs. Width options typically span from 1mm to 200mm, while thickness can range from 0.1mm to 10mm. This variety allows for precise customization to meet specific application requirements, whether it's for intricate medical devices or large-scale industrial equipment.

Moreover, titanium flat wire is produced in various grades, including commercially pure titanium and different titanium alloys. Each grade offers a unique combination of properties, such as enhanced strength, improved heat resistance, or optimized workability. For instance, Grade 5 titanium (Ti-6Al-4V) is widely used in aerospace and medical applications due to its excellent strength-to-weight ratio and biocompatibility. The availability of different grades ensures that it can be tailored to meet the specific performance criteria of diverse industries and applications.

Applications and Future Prospects of Titanium Flat Wire

Expanding Industrial Applications

The unique properties of titanium flat wire have led to its adoption in an ever-expanding range of industrial applications. In the chemical industry, its corrosion resistance makes it invaluable for constructing reactors, heat exchangers, and storage tanks that handle aggressive chemicals. The energy sector utilizes titanium flat wire in the production of heat exchangers for power plants and components for renewable energy systems, such as solar panels and wind turbines.

In the sports industry, titanium flat wire is gaining popularity for its lightweight and high-strength characteristics. It's used in the manufacturing of high-performance bicycle frames, golf club heads, and tennis racket frames. The material's durability and resistance to fatigue make it ideal for these applications, where repeated stress and impact are common. As industries continue to seek materials that offer superior performance and longevity, the applications for titanium flat wire are likely to expand further.

Advancements in Aerospace and Defense

The aerospace and defense sectors continue to be significant drivers of innovation in titanium flat wire applications. In aircraft construction, titanium flat wire is used in critical components such as hydraulic systems, landing gear, and engine parts. Its high strength-to-weight ratio contributes to fuel efficiency and overall performance improvements in modern aircraft designs.

In the realm of space exploration, the product plays a crucial role in the construction of satellites, space probes, and other spacecraft components. Its ability to withstand extreme temperature variations and resist the corrosive effects of atomic oxygen in low Earth orbit makes it an indispensable material for space applications. As space exploration and commercial space activities continue to evolve, the demand for high-performance materials like titanium flat wire is expected to grow, driving further innovations in its production and application.

Emerging Technologies and Future Prospects

The future of titanium flat wire looks promising, with emerging technologies opening up new avenues for its application. In the field of additive manufacturing, it is being explored as a feedstock material for 3D printing complex structures with intricate geometries. This development could revolutionize the production of custom medical implants, aerospace components, and other high-value parts.

Nanotechnology is another area where titanium flat wire shows potential for groundbreaking applications. Research is ongoing into the development of titanium-based nanomaterials, which could lead to advancements in areas such as energy storage, water purification, and advanced sensors. As these technologies mature, they are likely to create new demand for specialized forms of titanium flat wire, driving innovation in manufacturing processes and material properties.

Conclusion

Titanium flat wire stands out as a remarkable material with a unique combination of properties that make it superior to many alternatives across various industries. Its exceptional strength-to-weight ratio, superior corrosion resistance, and biocompatibility offer significant advantages in aerospace, medical, marine, and industrial applications. The versatility in manufacturing processes, customizable surface finishes, and wide range of available sizes and grades further enhance its appeal. As industries continue to evolve and new technologies emerge, it is poised to play an increasingly important role in driving innovation and solving complex engineering challenges.

Are you looking for high-quality titanium flat wire for your next project? At Baoji Chuanglian New Metal Material Co., Ltd., we specialize in manufacturing precision titanium products, including titanium flat wire, to meet the diverse needs of our global clientele. As a reliable titanium flat wire factory, we are dedicated to delivering products that ensure exceptional quality and performance. With over a decade of experience in titanium product machining and research, we offer a wide range of titanium solutions for various industries. To learn more about our titanium flat wire and other products, or to discuss your specific requirements, please contact us at info@cltifastener.com or djy6580@aliyun.com.

FAQ

What are the key advantages of using titanium flat wire?

Titanium flat wire offers exceptional strength-to-weight ratio, superior corrosion resistance, and biocompatibility, making it ideal for aerospace, medical, and marine applications.

How is titanium flat wire manufactured?

Titanium flat wire is produced using techniques such as cold rolling, hot rolling, annealing, and pickling, allowing for precise control over dimensions and properties.

What surface finishes are available for titanium flat wire?

Surface finishes include bright, polished, pickled, acid-cleaned, and sandblasted, each offering specific characteristics for different applications.

What industries commonly use titanium flat wire?

Titanium flat wire is widely used in aerospace, medical devices, chemical processing, energy, and sports equipment industries.

References

1. Smith, J. R. (2020). "Titanium Alloys in Aerospace Applications: Properties and Processing." Journal of Aerospace Engineering, 33(4), 215-230.

2. Johnson, M. K., & Brown, L. S. (2019). "Biocompatibility and Osseointegration of Titanium Implants: A Comprehensive Review." Journal of Biomaterials Science, 30(14), 1287-1302.

3. Chen, Q., & Thouas, G. A. (2015). "Metallic implant biomaterials." Materials Science and Engineering: R: Reports, 87, 1-57.

4. Williams, D. F. (2008). "On the mechanisms of biocompatibility." Biomaterials, 29(20), 2941-2953.

5. Peters, M., Kumpfert, J., Ward, C. H., & Leyens, C. (2003). "Titanium alloys for aerospace applications." Advanced Engineering Materials, 5(6), 419-427.