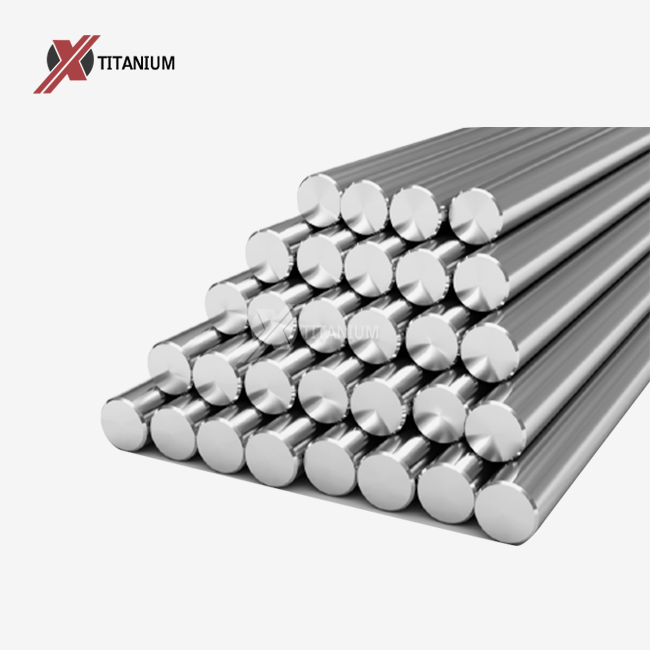

Understanding Pure Titanium Rods: Composition and Properties

Chemical Composition and Grades

Pure titanium rods are primarily composed of elemental titanium, with minimal amounts of impurities. The American Society for Testing and Materials (ASTM) classifies pure titanium into four grades based on the levels of oxygen, nitrogen, carbon, hydrogen, and iron present:

- Grade 1: The purest form, with the highest ductility and lowest strength

- Grade 2: The most commonly used grade, balancing strength and ductility

- Grade 3: Higher strength than Grade 2, with slightly reduced ductility

- Grade 4: The highest strength among unalloyed grades, with the lowest ductility

Each grade offers unique characteristics, allowing manufacturers to select the most appropriate type for specific applications. Baoji Chuanglian New Metal Material Co., Ltd. produces pure titanium rods in various grades to meet diverse industry requirements.

Physical Properties

Pure titanium rods exhibit remarkable physical properties that contribute to their widespread use:

- Density: Approximately 4.5 g/cm³, making it significantly lighter than steel

- Melting Point: Around 1668°C (3034°F), enabling use in high-temperature applications

- Thermal Conductivity: Lower than many metals, providing insulation properties

- Electrical Resistivity: Higher than many metals, useful in certain electrical applications

These physical properties make pure titanium rods ideal for applications requiring low weight and high thermal stability.

Mechanical Properties

The mechanical properties of pure titanium rods vary depending on the grade and manufacturing process:

- Tensile Strength: Ranges from 240 MPa (Grade 1) to 550 MPa (Grade 4)

- Yield Strength: Varies from 170 MPa (Grade 1) to 480 MPa (Grade 4)

- Elongation: Between 15% (Grade 4) and 24% (Grade 1)

- Hardness: Ranges from 100 to 260 Brinell, depending on the grade

These properties can be further enhanced through various heat treatment and processing techniques, allowing for customization to meet specific application requirements.

Manufacturing Processes and Surface Treatments

Production Methods

Pure titanium rods are manufactured using several techniques to achieve the desired properties and dimensions:

- Cold Rolling: Produces rods with improved strength and surface finish

- Hot Rolling: Allows for larger diameter rods and better ductility

- Extrusion: Creates rods with consistent cross-sections and properties

- Forging: Enhances strength and refines grain structure

Each method imparts unique characteristics to the titanium rods, influencing their final properties and suitability for different applications.

Heat Treatment

Heat treatment processes are crucial in optimizing the properties of pure titanium rods:

- Annealing: Reduces internal stresses, improves ductility, and enhances machinability

- Stress Relieving: Minimizes residual stresses from manufacturing processes

- Solution Treatment: Prepares the material for subsequent aging treatments

These heat treatment methods allow manufacturers to tailor the mechanical properties of pure titanium rods to meet specific application requirements.

Surface Treatments

Various surface treatments are applied to pure titanium rods to enhance their performance and appearance:

- Polishing: Creates a smooth, reflective surface for aesthetic or functional purposes

- Pickling: Removes surface impurities and improves corrosion resistance

- Acid Cleaning: Eliminates surface contaminants and oxide layers

- Sandblasting: Produces a matte finish and improves adhesion for coatings

- Anodizing: Forms a protective oxide layer, enhancing corrosion resistance and aesthetics

These surface treatments not only improve the appearance of pure titanium rods but also enhance their performance in various environments and applications.

Applications and Industry Uses of Pure Titanium Rods

Aerospace Industry

In the aerospace sector, pure titanium rods are prized for their exceptional strength-to-weight ratio and resistance to fatigue:

- Structural components in aircraft frames and engines

- Fasteners and connectors for critical assemblies

- Landing gear components subjected to high stress

- Spacecraft structural elements and propulsion systems

The use of pure titanium rods in aerospace applications contributes to lighter, more fuel-efficient aircraft and spacecraft capable of withstanding extreme conditions.

Medical and Dental Applications

The biocompatibility and corrosion resistance of pure titanium rods make them invaluable in medical and dental fields:

- Orthopedic implants, such as hip and knee replacements

- Dental implants and prosthetic components

- Surgical instruments and medical devices

- Cardiovascular stents and pacemaker casings

Pure titanium rods used in medical applications promote osseointegration and reduce the risk of allergic reactions, ensuring long-term success of implants and devices.

Chemical and Industrial Uses

The corrosion resistance and durability of pure titanium rods make them essential in various chemical and industrial applications:

- Heat exchangers and condensers in chemical processing plants

- Pump shafts and impellers for handling corrosive fluids

- Electrodes in chlor-alkali production

- Pressure vessels and piping systems in aggressive environments

In these applications, pure titanium rods offer extended service life and reduced maintenance requirements compared to other materials.

Marine and Offshore Applications

The resistance to saltwater corrosion makes pure titanium rods ideal for marine environments:

- Propeller shafts and rudder components

- Desalination plant equipment

- Offshore oil and gas platform components

- Subsea valves and actuators

Pure titanium rods in marine applications provide long-term reliability and reduced maintenance costs in harsh saltwater environments.

Sports and Leisure Equipment

The lightweight and high-strength properties of pure titanium rods are leveraged in various sports and leisure products:

- Golf club shafts and heads

- Bicycle frames and components

- Tennis racket frames

- Camping and hiking equipment

In these applications, pure titanium rods contribute to improved performance, durability, and comfort for users.

Conclusion

Pure titanium rods are versatile and high-performance materials that find applications across numerous industries. Their unique combination of low density, high strength, excellent corrosion resistance, and biocompatibility makes them indispensable in aerospace, medical, chemical, marine, and sports industries. The various grades, manufacturing processes, and surface treatments available allow for customization to meet specific application requirements. As technology advances and new applications emerge, the demand for pure titanium rods is likely to continue growing, driving innovation in production methods and expanding their use in cutting-edge industries.

If you're looking for high-quality pure titanium rods for your next project, look no further than Baoji Chuanglian New Metal Material Co., Ltd. With over a decade of experience in titanium product manufacturing and research, we offer a wide range of pure titanium rods tailored to your specific needs. Our products meet international standards and are used in diverse applications worldwide. Contact us today at info@cltifastener.com or djy6580@aliyun.com to learn more about our pure titanium rods and how they can benefit your industry.

FAQ

What are the main advantages of using pure titanium rods?

Pure titanium rods offer excellent strength-to-weight ratio, corrosion resistance, biocompatibility, and high temperature stability.

How do different grades of pure titanium rods compare?

Grades 1-4 offer varying levels of strength and ductility, with Grade 1 being the most ductile and Grade 4 the strongest.

What industries commonly use pure titanium rods?

Aerospace, medical, chemical processing, marine, and sports industries frequently utilize pure titanium rods.

Can pure titanium rods be customized for specific applications?

Yes, through various manufacturing processes, heat treatments, and surface finishes, pure titanium rods can be tailored to meet specific requirements.

Are pure titanium rods more expensive than other materials?

While initially more costly than some materials, the long-term benefits in performance and durability often make pure titanium rods a cost-effective choice.

References

1. Lutjering, G., & Williams, J. C. (2007). Titanium (2nd ed.). Springer-Verlag Berlin Heidelberg.

2. Donachie, M. J. (2000). Titanium: A Technical Guide (2nd ed.). ASM International.

3. Froes, F. H. (2015). Titanium: Physical Metallurgy, Processing, and Applications. ASM International.

4. Peters, M., Hemptenmacher, J., Kumpfert, J., & Leyens, C. (2003). Titanium and Titanium Alloys: Fundamentals and Applications. Wiley-VCH.

5. Rack, H. J., & Qazi, J. I. (2006). Titanium alloys for biomedical applications. Materials Science and Engineering: C, 26(8), 1269-1277.