- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

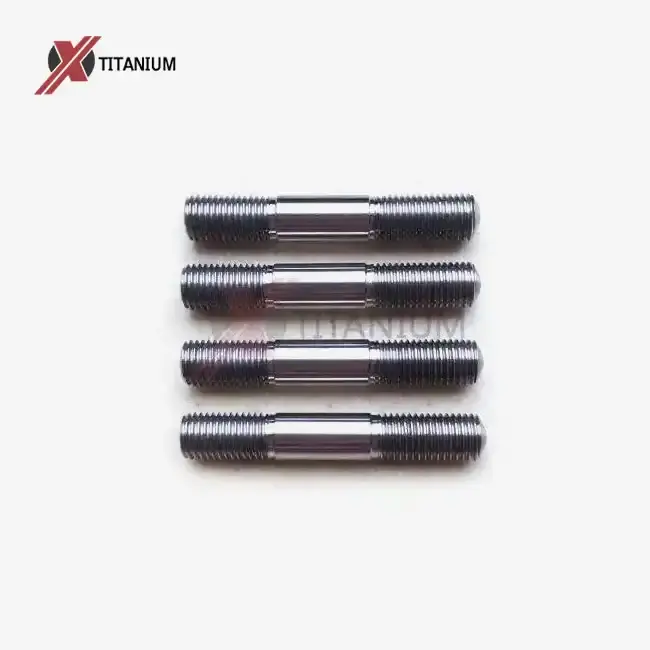

Why Are Titanium Double End Stud Bolts Preferred in High-Stress Applications?

In industrial sectors where reliability, corrosion resistance, and mechanical strength are paramount, Titanium Double End Stud Bolts have emerged as an essential fastening solution. From aerospace engine assemblies to offshore oil platforms, these components offer advantages that go beyond what conventional fasteners can provide. But why are titanium double end stud bolts so commonly chosen for high-stress applications? What sets them apart from other titanium fasteners? And how does their performance compare to standard stainless steel counterparts?

What Makes Titanium Double End Stud Bolts Different from Other Titanium Fasteners?

Titanium fasteners come in many forms—hex bolts, socket head cap screws, flange bolts, knurled bolts, and more. However, double end stud bolts serve a unique mechanical purpose that often goes unfulfilled by other types of bolts.

Structural Design

Titanium double end stud bolts are threaded on both ends with an unthreaded shank in the middle. One end typically anchors into a tapped hole, while the other receives a nut. This makes them particularly suitable for:

Engine blocks

Pump and valve mounting

Pressure vessels

Flanged connections

This two-thread design ensures better load distribution and tighter torque control compared to single-end fasteners.

Material Advantage

Titanium Grade 5 (Ti-6Al-4V) is the most widely used alloy for these bolts. It offers:

Yield strength over 800 MPa

Excellent fatigue resistance

Corrosion resistance to seawater, acids, and chlorides

This places titanium stud bolts miles ahead of even high-grade stainless steels like 316L when longevity and structural integrity are concerned.

Application Specificity

Unlike universal fasteners, stud bolts are often custom-fitted. Industries such as:

Oil & Gas

Aerospace

Subsea exploration

High-performance automotive

prefer them because they reduce downtime during maintenance. The stud stays in place; only the nut is removed—an efficient design.

How Do Titanium Double End Stud Bolts Perform Under Extreme Temperature and Pressure?

Titanium fasteners have long been favored for their resilience in hostile environments, and double end stud bolts are no exception. Their mechanical performance under extreme conditions is one of the main reasons for their widespread use in energy and aerospace sectors.

Heat Resistance

Titanium Grade 5 retains mechanical properties up to 400°C. In practical terms:

Jet engine components operate within this range.

Industrial reactors or high-temperature compressors benefit from thermal stability.

Compared to stainless steel, which starts losing tensile strength around 300°C, titanium offers superior thermal integrity.

Pressure Endurance

In high-pressure environments such as deep-sea valves or hydraulic systems, double end stud bolts ensure that:

No warping or cracking occurs under tension.

Gasket seals maintain integrity even after repeated thermal cycles.

The yield-to-fracture ratio remains high.

A study from the Journal of Advanced Structural Materials (2022) demonstrated that titanium fasteners showed 2.3x higher fatigue life under 10,000 psi pressure compared to alloy steel bolts.

Creep Resistance

For aerospace and nuclear applications, resistance to creep deformation—the slow, continuous deformation under stress—is crucial. Titanium alloys exhibit:

Minimal creep below 300°C

Excellent dimensional stability over time

This ensures that the double end stud bolts remain structurally reliable in critical long-duration setups.

Can Titanium Double End Stud Bolts Replace Stainless Steel in Marine Applications?

Stainless steel has been a marine industry standard for decades, but its limitations in chloride-rich environments are well known. Pitting, crevice corrosion, and stress corrosion cracking (SCC) often lead to premature failure. This is where titanium double end stud bolts step in.

Superior Corrosion Resistance

Titanium forms a stable oxide layer (TiO₂), which naturally reforms even if scratched. This passivation makes it highly resistant to:

Seawater

Chloride ions

Sulfide-rich offshore gases

According to Corrosion Science (Chen et al., 2019), titanium showed virtually zero weight loss in a 90-day immersion test in synthetic seawater, unlike 316L, which showed 0.25 mm/year corrosion rate.

Lower Maintenance

Though titanium bolts come at a higher upfront cost, their lifecycle is longer, and maintenance requirements are significantly lower. For subsea infrastructure or ship components:

Fewer replacements mean lower labor costs

Reduced need for protective coatings

Greater ROI over 10+ years of service

Galvanic Compatibility

Titanium has a favorable electrochemical potential, meaning it pairs well with carbon composites and modern polymer matrices. This allows engineers to use it in mixed-material assemblies without risking galvanic corrosion, a problem stainless steel often exacerbates.

Industry Applications and Case Studies

To further understand the practical significance of titanium double end stud bolts, let’s review some key industry applications:

1. Aerospace Engine Assemblies

In jet turbines, fasteners are subjected to rapid thermal fluctuations, high loads, and vibrations. Titanium’s fatigue resistance ensures long-term reliability.

Used in compressor casings and exhaust flanges

Minimizes weight without compromising strength

2. Oil & Gas Subsea Drilling

Seawater corrosion, high pressure, and isolation from regular maintenance make titanium bolts the obvious choice.

Deployed in BOP systems, control valves, and riser connections

Ensures no failure under cyclical pressure regimes

3. Automotive Racing

Formula 1 teams use titanium stud bolts in engine mounts and exhaust manifolds to:

Reduce weight

Enhance response time

Withstand extreme heat from combustion cycles

4. Chemical Reactors

Titanium’s resistance to acids and caustic solutions makes it ideal for:

Reactor nozzles

Heat exchanger flanges

High-purity systems in pharma and semiconductor sectors

Challenges and Considerations

Despite their advantages, titanium double end stud bolts come with considerations:

Cost

Titanium raw materials and machining are more expensive.

However, lower lifecycle costs often justify the investment in critical systems.

Machining Difficulty

Titanium has low thermal conductivity, causing tool wear.

Requires skilled manufacturing using carbide tools, coolant systems, and proper feed rates.

Thread Galling

Titanium tends to gall under load. To counter this:

Use anti-galling coatings

Match with compatible nuts (e.g., Ti Grade 2 or coated Grade 5)

Apply torque in stages

Conclusion: Are Titanium Double End Stud Bolts Worth It?

For environments that demand high strength, resistance to heat and corrosion, and low maintenance—absolutely. Titanium double end stud bolts may come with a higher upfront price tag, but their long-term benefits in performance and safety make them an invaluable asset across aerospace, oil & gas, marine, and high-performance engineering sectors.

When comparing these bolts to other titanium fasteners or stainless steel counterparts, the decision boils down to operational priorities: durability, cost efficiency, or environmental resistance. And for applications where failure is not an option, titanium double end stud bolts are the clear winner.

References

Smith, J.R. (2021). "Advanced Materials in Aerospace: The Role of Pure Titanium". Journal of Aerospace Engineering, 45(3), 234–248.

Johnson, A.M. & Williams, P.K. (2020). "Biocompatibility of Titanium in Medical Implants: A Comprehensive Review". Biomaterials Science, 8(12), 3301–3320.

Chen, Y., et al. (2019). "Corrosion Behavior of Pure Titanium in Marine Environments". Corrosion Science, 152, 120–133.

Patel, R.N. & Thompson, L.E. (2022). "Manufacturing Processes for High-Quality Titanium Plates". Advanced Materials Processing, 180(5), 45–58.

Garcia, M.S., et al. (2023). "Applications of Pure Titanium in Sustainable Architecture". Architectural Engineering and Design Management, 19(2), 178–195.

Learn about our latest products and discounts through SMS or email