- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why Australia Bike Brands Choose China Titanium Sprocket Nuts

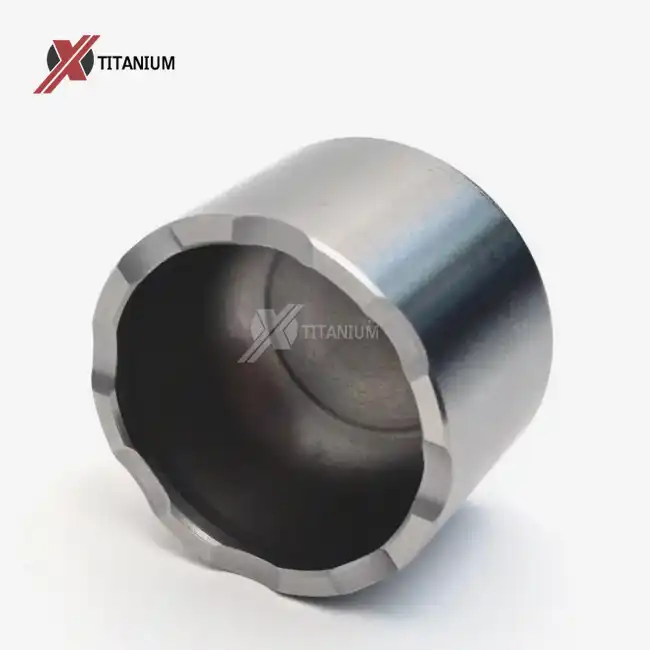

Australian bike brands increasingly turn to Chinese manufacturers for titanium sprocket nuts due to the exceptional combination of advanced manufacturing capabilities, cost-effectiveness, and superior product quality. China's established titanium processing infrastructure enables the production of Grade 5 (Ti-6Al-4V) sprocket nuts that meet stringent international standards while offering approximately 50% weight reduction compared to steel equivalents. The strategic advantage lies in China's ability to provide customized solutions with various surface treatments and colors, ensuring optimal performance across diverse riding conditions. This procurement trend reflects the industry's recognition of China's technological expertise in titanium component manufacturing and its capacity to deliver consistent quality at competitive pricing.

Understanding the Demand: Why Titanium Sprocket Nuts Matter to Australia Bike Brands?

Critical Performance Requirements in Australian Conditions

Components for bicycles and motorcycles are subject to an entirely new set of requirements as a result of Australia's varied topography and difficult weather conditions. The producers of bicycles demand fastening solutions that are able to retain the structural integrity of their products in harsh circumstances, whether they are located in coastal areas with significant salt exposure or in the dry settings of the outback. The remarkable resistance to corrosion and mechanical strength features of titanium sprocket nuts allow them to provide a solution to these difficulties.

When it comes to performance applications, the amount of strength that titanium components possess in comparison to their weight becomes very important. Bicycle manufacturers in Australia that specialize on competitive traveling by bicycle and off-road adventures are aware that every gram decrease leads to improvements in acceleration, working with, and rider endurance. Titanium fasteners have a mechanical strength of around 950 MPa, while at the same time retaining a weight that is much lower than that of standard steel counterparts.

Market-Driven Procurement Trends

Components that are precision-engineered and aimed at improving total product distinction have become more popular among Australian manufacturers. This tendency is in line with the expectations of consumers for bicycles that are lightweight, sturdy, and capable of managing the many weather conditions that are found in Australia. It is becoming more important for procurement managers to provide priority to suppliers that are able to offer documentation for technical purposes, material certifications, and quality that is consistent throughout manufacturing batches.

The growing emphasis on sustainability also influences component selection. Titanium's longevity reduces replacement frequency, supporting environmental objectives while delivering long-term cost benefits. Australian brands leverage these characteristics to position their products as premium, environmentally conscious options in competitive markets.

Comparing Titanium Sprocket Nuts: China vs Other Sources

Material Performance Analysis

Titanium displays better qualities across numerous performance parameters when compared to alternatives made of steel and aluminum when it comes to the evaluation of fastening solutions. As a result of the corrosion resistant capabilities, problems about rust, oxygen consumption, and chemical deterioration, which are often associated with steel components in maritime and industrial settings, are eliminated. This resilience proves to be especially useful for applications in Australia that are subjected to incoming salt spray and a wide range of weather conditions.

When the performance of the whole lifetime is taken into consideration, the juxtaposition becomes more interesting. Although the initial prices of titanium components are higher than those of steel counterparts, advantageous total cost associated with ownership estimates are produced as a result of titanium's longer service life and lower maintenance needs. Chinese manufacturers have improved their manufacturing techniques in order to maximize these benefits while simultaneously maintaining price structures that are competitive throughout the industry.

Chinese Manufacturing Advantages

China's titanium processing industry has developed comprehensive capabilities that extend beyond basic manufacturing, enabling the production of high-specification components like titanium sprocket nuts. The integration of advanced CNC machining, precise heat treatment protocols, and sophisticated surface finishing techniques enables Chinese manufacturers to produce components meeting ASTM B348, ISO, DIN, and AMS standards consistently.

It becomes clear that cost-effectiveness is a crucial component, and this is accomplished without lowering quality requirements. China's manufacturers get the benefits of well-established supply chains, savings of scale, and ongoing process improvements, all of which translate into bargain prices for Australian consumers. This benefit becomes especially noticeable when it comes to the unique specs and diverse batch sizes that are needed by various bike manufacturers.

There have been many bicycle manufacturers in Australia that have recorded successful collaborations with Chinese titanium suppliers. These manufacturers have reported that the delivery dependability, technical support flexibility, and quality consistency of their products match or surpass the standards that were set with conventional suppliers operating in other locations.

The Manufacturing Edge: How China Produces High-Quality Titanium Sprocket Nuts?

Advanced Processing Technologies

Chinese production facilities for titanium use cutting-edge computer numerical control (CNC) machining centers that are able to achieve the exact dimensional tolerances that are necessary for critical mounting applications. Additionally, the machining techniques contain multi-axis capabilities, which make it possible to create complicated geometries while yet adhering to surface quality criteria. By using these technical skills, it is guaranteed that every component will conform to the precise standards for link pitch, flange circumference and socket dimensions.

Heat treatment protocols represent another area where Chinese manufacturers demonstrate technical excellence. Controlled atmosphere furnaces and precise temperature management systems ensure consistent metallurgical properties across production batches. This consistency proves essential for maintaining the 950 MPa tensile strength characteristics that make titanium components suitable for high-stress applications.

Polishing, anodizing, and nitriding are examples of surface treatment procedures that are available from Chinese manufacturers. These treatments improve not only the visual appeal of the finish but also the functional performance of the product. The capability of providing components in a variety of hues, such as natural titanium, gold, the shades of blue, purple, black, additionally rainbow finishes, enables Australian businesses to include these components into the shape of them aesthetics in a seamless manner.

Quality Control and Certification Systems

Every step of the production process is subject to stringent quality control measures, beginning with the verification of raw materials and continuing all the way through the final inspection processes. Prior to shipping, Chinese manufacturers put their products through extensive testing methods that confirm the material qualities, dimensional correctness, and visual quality of their products. The processes in question are in accordance with the global norms and offer support for the documentation needs that are anticipated by procurement teams in Australia.

Every step of the production process is subject to stringent quality control measures, beginning with the verification of raw materials and continuing all the way through the final inspection processes. Prior to shipping, Chinese manufacturers put their products through extensive testing methods that confirm the material qualities, dimensional correctness, and visual quality of their products. The processes in question are in accordance with the global norms and offer support for the documentation needs that are anticipated by procurement teams in Australia.

How to Choose and Integrate Titanium Sprocket Nuts in Your Supply Chain?

Technical Specification Evaluation

Selecting appropriate titanium fasteners, such as titanium sprocket nuts, requires careful evaluation of mechanical requirements, dimensional compatibility, and application-specific performance criteria. The Grade 5 (Ti-6Al-4V) alloy composition provides optimal balance between strength, weight, and corrosion resistance for most bicycle and motorcycle applications. Understanding these material properties enables procurement professionals to specify components that deliver required performance while optimizing cost considerations.

The assortment of sizes includes typical alternatives such as M6, M8, the M10, and M12 configurations. Additionally, there are bespoke sizes available to satisfy certain design needs. When it comes to unique bike designs that call for non-standard attachment systems, the option to specify specific measurements proves to be very helpful.

Installation and maintenance considerations play crucial roles in long-term component performance. Titanium's resistance to galling requires specific torque specifications and assembly procedures that differ from steel components. Proper installation ensures optimal joint integrity while preventing damage to expensive titanium threads.

Supply Chain Integration Strategies

It is necessary to take into account lead times, management of inventory, and logistics coordination in order to achieve effective supply chain integration. The manufacturing schedules of Chinese manufacturers are often flexible, allowing them to handle both prototype numbers and full deliveries. This adaptability helps to support the development of new products while also ensuring that enough inventory levels are maintained to meet current manufacturing needs.

The processes for shipping and complying with customs regulations need careful attention to be paid to the paperwork, classification, and legal guidelines that are special to titanium items. A full support system for these procedures is provided by experienced Chinese suppliers. This assistance includes the provision of appropriate material certifications, documentation of the place of origin, and technical standards that are needed by the customs authorities in Australia.

Partnership & Procurement: Navigating the Australian-Chinese Supplier Relationship

Supplier Selection and Evaluation

The evaluation of technical skills, quality certificates, and manufacturing capacity are all necessary steps in the process of locating certified Chinese titanium suppliers. A full review of production processes, quality systems, including customer service skills is necessary for the development of successful collaborations. It is possible to get useful insights into the capabilities and dependability of a supplier via the use of site inspections, sample assessments, and reference checks.

Australian firms are able to distinguish their goods by using one-of-a-kind fastener expectations, surface treatments, additionally packaging alternatives because to the OEM and customisation possibilities that are accessible from Chinese manufacturers. Within the context of sustaining component the quality and performance requirements, these competencies contribute to the maintenance of brand identity.

Risk Management and Relationship Development

Effective risk mitigation strategies address quality assurance, intellectual property protection, and supply continuity concerns. For the production of titanium sprocket nuts, establishing clear quality agreements, regular communication protocols, and contingency planning helps ensure reliable supply chain performance. Long-term partnership development benefits both parties through improved understanding, process optimization, and collaborative problem-solving approaches.

The negotiation of bulk orders may result in considerable cost savings while also ensuring that proper inventory levels are maintained for production planning. It is common for Chinese manufacturers to provide price structures that are dependent on volume. These systems reward commitments that last forever and greater purchase volumes, which helps Australian customers achieve their cost control goals.

Chuanglian: Your Trusted Partner for Premium Titanium Sprocket Nuts

By using more than 10 years of specialized knowledge in titanium the analysis and machining, Baoji Hong Kong New Metal Material Co., Ltd. has established itself as a leading producer and supplier of premium titanium components. In order to provide outstanding titanium motor nuts and other fastening solutions, our firm, which is situated in Baoji City, which is well known as the "City of Titan Steel," combines technical innovation with complete production capabilities.

The variety of products that we provide includes specialized titanium sprocket nuts that are made from pure titanium while participating titanium alloys, more especially Grade 5 (Ti-6Al-4V), respectively, materials that are in compliance with demanding international requirements. By using cutting-edge CNC machining technologies, we are able to achieve accurate dimensional tolerances while yet preserving the remarkable mechanical qualities that are characteristic of our manufactured components. Our surface treatment instruments include polishing, oxidization, which and nitriding choices, which are available in natural titanium,which is gold, blue, green, green, black, and rainbow finishes. Additionally, we provide black and rainbow finishes.

The advantages of partnering with Chuanglian extend beyond product quality to encompass comprehensive technical support, flexible customization options, and reliable delivery performance. Our strict quality control systems ensure every component meets international standards including ASTM B348, ISO, DIN, and AMS specifications. The proven track record of serving well-known companies worldwide demonstrates our commitment to excellence and customer satisfaction.

Our end-to-end service offerings, which include everything from first inquiries and technical consultations to order processing and extensive after-sales care, are beneficial to Australian bike companies. In order to guarantee the smooth incorporation of our titanium elements into your product lines, our staff offers experienced help on the selection of materials, the optimization of specifications, and the requirements that are particular to the application. Chuanglian is a perfect partner for purchasing personnel who are looking for trusted titanium fastener solutions because of the combination of affordable price, outstanding quality, and prompt customer service.

Conclusion

Australian bike brands increasingly recognize the strategic advantages of sourcing titanium sprocket nuts from Chinese manufacturers who demonstrate technical excellence, cost-effectiveness, and reliable supply chain performance. The combination of advanced manufacturing capabilities, comprehensive customization options, and competitive pricing creates compelling value propositions for procurement professionals seeking to enhance product performance while managing costs.

China's established titanium processing infrastructure, supported by rigorous quality control systems and international certifications, provides confidence in component reliability and consistency. As the bicycle industry continues evolving toward lightweight, high-performance solutions, partnerships with qualified Chinese titanium suppliers offer sustainable pathways for achieving competitive advantages in demanding market environments.

FAQ

What makes titanium sprocket nuts superior to steel alternatives?

Titanium sprocket nuts offer approximately 50% weight reduction compared to steel equivalents while maintaining superior tensile strength of 950 MPa. The excellent corrosion resistance eliminates concerns about rust and oxidation, particularly important for Australian coastal and varied climate conditions. Additionally, titanium's resistance to harsh chemicals and temperature stability ensure consistent performance across diverse operating environments.

How do I verify the quality of Chinese titanium suppliers?

Quality verification involves evaluating certifications such as ASTM B348, ISO, DIN, and AMS compliance, requesting material certificates and test reports, and conducting sample evaluations. Reputable suppliers provide comprehensive documentation, maintain transparent communication, and welcome facility inspections. References from existing customers and industry reputation also serve as valuable quality indicators.

What customization options are available for titanium sprocket nuts?

Chinese manufacturers offer extensive customization including custom sizes beyond standard M6, M8, M10, M12 options, various surface treatments such as polishing, anodizing, and nitriding, and multiple color finishes including natural titanium, gold, blue, green, purple, black, and rainbow. Thread specifications, flange dimensions, and socket sizes can be tailored to specific application requirements.

What are the typical lead times for titanium component orders from China?

Lead times vary depending on order complexity, quantity, and customization requirements. Standard components typically require 2-4 weeks, while custom specifications may extend to 4-6 weeks. Experienced suppliers provide accurate scheduling information during quotation processes and maintain communication throughout production cycles to ensure delivery expectations are met.

Partner with Chuanglian for Superior Titanium Sprocket Nuts

Transform your bicycle manufacturing capabilities with Chuanglian's premium titanium sprocket nuts designed specifically for demanding Australian applications. Our Grade 5 titanium components deliver the perfect balance of strength, weight reduction, and corrosion resistance that Australian bike brands require. Experience the difference that over ten years of titanium processing expertise makes in component quality and reliability. Contact our technical team at info@cltifastener.com or djy6580@aliyun.com to discuss your specific requirements and discover why leading manufacturers choose Chuanglian as their trusted titanium sprocket nuts supplier.

References

1. Australian Bicycle Manufacturing Industry Report: Trends in High-Performance Component Sourcing, 2023

2. Titanium Alloy Applications in Bicycle Engineering: A Technical Analysis of Grade 5 Ti-6Al-4V Performance Characteristics

3. Global Titanium Supply Chain Analysis: China's Manufacturing Capabilities and Quality Standards in Precision Components

4. Corrosion Resistance Properties of Titanium Fasteners in Marine and Industrial Applications: Australian Case Studies

5. Cost-Benefit Analysis of Titanium vs. Steel Components in High-Performance Bicycle Manufacturing

6. International Standards and Certification Requirements for Titanium Fasteners: ASTM, ISO, DIN, and AMS Compliance Guidelines

Learn about our latest products and discounts through SMS or email