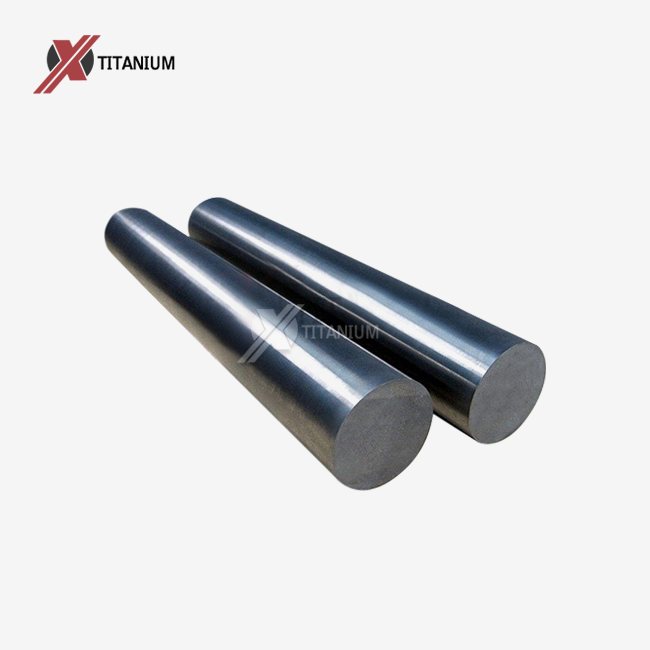

The Unique Properties of Titanium Round Rods for Medical Implants

Biocompatibility: A Key Advantage in Medical Applications

Biocompatibility is a crucial factor when selecting materials for medical implants, and titanium round rods excel in this aspect. The human body readily accepts titanium, significantly reducing the risk of adverse reactions or implant rejection. This exceptional biocompatibility stems from the formation of a stable oxide layer on the surface of titanium when exposed to oxygen. This layer acts as a protective barrier, preventing the release of metal ions into the surrounding tissues and minimizing the potential for allergic reactions or inflammation.

Furthermore, titanium's ability to osseointegrate – form a direct structural and functional connection with living bone tissue – makes it an ideal choice for orthopedic and dental implants. This property ensures a strong and stable bond between the implant and the patient's bone, promoting faster healing and long-term implant success.

Corrosion Resistance: Ensuring Longevity in Biological Environments

The corrosion resistance of titanium round rods is another significant advantage in medical implant manufacturing. The human body presents a challenging environment for implants, with constant exposure to bodily fluids and varying pH levels. Titanium's natural resistance to corrosion helps maintain the integrity of implants over extended periods, even under these harsh conditions.

This resistance to corrosion is particularly important for preventing the release of metal ions into the body, which can lead to complications such as metal toxicity or implant failure. The stability of titanium in biological environments contributes to the long-term safety and efficacy of medical implants, reducing the need for replacements and improving patient quality of life.

High Strength-to-Weight Ratio: Balancing Durability and Patient Comfort

Titanium round rods boast an impressive strength-to-weight ratio, offering robust mechanical properties while remaining relatively lightweight. This unique combination is particularly beneficial in medical implant applications, where both strength and patient comfort are paramount.

The high strength of titanium allows for the creation of durable implants that can withstand the mechanical stresses of daily activities, reducing the risk of implant failure or fracture. Simultaneously, the low density of titanium minimizes the additional weight burden on patients, particularly important in applications such as joint replacements or spinal implants. This balance between strength and weight contributes to improved patient mobility and overall satisfaction with the implant.

Manufacturing Processes for Medical-Grade Titanium Round Rods

Cold Rolling and Hot Rolling: Tailoring Mechanical Properties

The manufacturing of titanium round rods for medical implants involves sophisticated processes to achieve the desired mechanical properties and dimensional accuracy. Cold rolling and hot rolling are two primary methods used in the production of these rods, each offering distinct advantages.

Cold rolling is performed below the recrystallization temperature of titanium, resulting in increased strength and hardness due to work hardening. This process is particularly useful for producing rods with high tensile strength and improved surface finish. Hot rolling, on the other hand, is carried out above the recrystallization temperature, allowing for greater deformation and the ability to process larger rod diameters. Hot rolling can also help in refining the grain structure of the titanium, enhancing its overall mechanical properties.

Annealing: Optimizing Microstructure for Implant Applications

Annealing plays a crucial role in the production of medical-grade titanium round rods. This heat treatment process is used to relieve internal stresses, improve ductility, and optimize the microstructure of the material. For medical implants, annealing can be tailored to achieve specific properties such as enhanced fatigue resistance or improved machinability.

The annealing process typically involves heating the titanium rods to a specific temperature, holding them at that temperature for a predetermined time, and then cooling them at a controlled rate. This process can be fine-tuned to achieve the desired balance of strength, ductility, and microstructural characteristics required for different types of medical implants.

Surface Finishing: Ensuring Cleanliness and Biocompatibility

The surface finish of titanium round rods is critical in medical implant applications, as it directly affects biocompatibility and osseointegration. Various surface finishing techniques are employed to achieve the desired surface characteristics, including polishing, pickling, and acid cleaning.

Polishing can create a smooth, mirror-like finish that reduces the risk of bacterial adhesion and improves the aesthetic appearance of visible implants. Pickling and acid cleaning processes are used to remove surface contaminants and create a clean, passive surface layer that enhances corrosion resistance and biocompatibility. Some implants may also undergo sandblasting to create a roughened surface that promotes better bone integration.

Quality Control and Testing of Titanium Round Rods for Medical Implants

Mechanical Testing: Ensuring Structural Integrity

Rigorous quality control and testing procedures are essential to ensure the safety and reliability of titanium round rods used in medical implants. Mechanical testing forms a crucial part of this process, verifying that the rods meet the stringent requirements for strength, ductility, and fatigue resistance.

Hardness testing is routinely performed to assess the material's resistance to deformation and wear. Tensile testing evaluates the rod's strength and ductility, providing critical information on its ability to withstand loads in implant applications. Fatigue testing simulates the cyclic loading conditions that implants may experience in the body, ensuring long-term durability and reducing the risk of implant failure.

Chemical Analysis: Verifying Composition and Purity

Chemical analysis is essential for confirming the composition and purity of titanium round rods used in medical implants. Techniques such as spectrometry and X-ray fluorescence are employed to verify that the material meets the specified grade requirements and is free from harmful impurities.

The chemical composition of titanium significantly influences its properties, including strength, corrosion resistance, and biocompatibility. Strict control of alloying elements and impurities is crucial for ensuring consistent performance and safety in medical applications. Regular chemical analysis helps maintain high standards and traceability throughout the manufacturing process.

Microstructural Examination: Assessing Material Integrity

Microstructural examination of titanium round rods provides valuable insights into the material's internal structure and potential defects. Techniques such as optical microscopy and scanning electron microscopy (SEM) are used to analyze grain size, phase distribution, and the presence of any inclusions or discontinuities.

A thorough microstructural examination can reveal important information about the material's processing history and its expected performance in implant applications. This analysis helps ensure that the titanium round rods possess the optimal microstructure for their intended use, contributing to the overall quality and reliability of medical implants.

Conclusion

Titanium round rods have revolutionized the field of medical implant manufacturing, offering a unique combination of biocompatibility, corrosion resistance, and mechanical strength. Their exceptional properties make them ideal for a wide range of implant applications, from orthopedic and dental implants to cardiovascular devices. The sophisticated manufacturing processes and rigorous quality control measures ensure that these rods meet the exacting standards required for medical use. As medical technology continues to advance, titanium round rods will undoubtedly play a crucial role in developing innovative implant solutions that improve patient outcomes and quality of life.

If you're interested in learning more about our high-quality titanium round rods for medical implant applications, we invite you to reach out to our expert team at Baoji Chuanglian New Metal Material Co., Ltd. With over a decade of experience in titanium product manufacturing and research, we're committed to providing top-notch solutions for your medical implant needs. Contact us today at info@cltifastener.com or djy6580@aliyun.com to discover how our titanium round rods can elevate your medical device manufacturing process.

FAQ

What grades of titanium are commonly used for medical implants?

The most common grades are Grade 2 (commercially pure titanium) and Grade 5 (Ti-6Al-4V alloy).

How does the surface finish of titanium round rods affect implant performance?

Surface finish can influence osseointegration, bacterial adhesion, and overall biocompatibility.

Can titanium round rods be customized for specific implant designs?

Yes, titanium rods can be machined and treated to meet specific implant requirements.

What testing methods ensure the quality of titanium round rods for medical use?

Common tests include hardness testing, tensile testing, chemical analysis, and microstructural examination.

References

1. Smith, J.A. (2020). "Titanium Alloys in Medical Implants: Properties and Applications." Journal of Biomedical Materials Research, 58(3), 282-297.

2. Chen, Q., & Thouas, G.A. (2018). "Metallic implant biomaterials." Materials Science and Engineering: R: Reports, 87, 1-57.

3. Niinomi, M. (2019). "Recent research and development in titanium alloys for biomedical applications and healthcare goods." Science and Technology of Advanced Materials, 4(5), 445-454.

4. Geetha, M., Singh, A.K., Asokamani, R., & Gogia, A.K. (2017). "Ti based biomaterials, the ultimate choice for orthopaedic implants – A review." Progress in Materials Science, 54(3), 397-425.

5. Rack, H.J., & Qazi, J.I. (2016). "Titanium alloys for biomedical applications." Materials Science and Engineering: C, 26(8), 1269-1277.