- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Rear Derailleur Titanium Screw

Material: Titanium alloy

Grade:Gr5(Ti6al4v)

Processing:CNC machined

Surface Treatment: Polishing,Anodizing, Nitriding

Color:Ti nature,Gold,Blue,Green,Purple,Black,Rainbow

Advantage:light, acid and alkali resistance, anti-corrosion, excellent mechanical strength etc.

Rear Derailleur Titanium Screw

Product Introduction

Looking for the perfect Rear Derailleur Titanium Screw for your high-performance cycling build? You've found the right place. Our premium titanium screws are specifically engineered for rear derailleur applications, delivering exceptional strength while reducing overall weight. These precision-machined fasteners feature superior corrosion resistance and long-lasting durability. Whether you're building a racing bike or upgrading your existing setup, our Rear Derailleur Titanium Screw components provide the reliability you need for optimal shifting performance.

Each screw undergoes strict quality control processes to ensure perfect thread engagement and dimensional accuracy. Our titanium material offers excellent mechanical properties that outperform traditional steel alternatives. You'll appreciate the weight savings without compromising on strength or reliability in demanding cycling conditions.

Technical Specifications

| Parameter | Specification |

|---|---|

| Material | Pure Titanium, Titanium Alloy |

| Grade | Gr5 (Ti6Al4V) |

| Standard | Customized |

| Processing Method | CNC Machined |

| Surface Treatment | Polishing, Anodizing, Nitriding |

| Available Colors | Natural Ti, Gold, Blue, Green, Purple, Black, Rainbow |

| Thread Accuracy | ±0.02mm |

| Surface Roughness | Ra 0.8-3.2μm |

| Temperature Range | -40°C to +400°C |

Key Features

Lightweight Construction: Our titanium screws weigh approximately 40% less than steel equivalents, helping reduce your bike's overall weight.

Superior Corrosion Resistance: Excellent protection against moisture, salt, and environmental elements ensures long-lasting performance.

High Strength-to-Weight Ratio: Grade 5 titanium alloy provides exceptional mechanical strength while maintaining minimal weight.

Precision Threading: CNC machining guarantees perfect thread engagement and secure installation.

Multiple Color Options: Choose from various anodized colors to match your bike's aesthetic.

Product Characteristics

Your cycling performance depends on reliable components that won't fail under pressure. Our titanium screws excel in harsh riding conditions where traditional fasteners might corrode or break. The material's natural properties resist galvanic corrosion when paired with carbon fiber or aluminum components.

Temperature fluctuations won't affect performance, making these screws ideal for riders in varying climates. The smooth surface finish reduces dirt accumulation and simplifies maintenance. Each Rear Derailleur Titanium Screw maintains its integrity through thousands of shift cycles.

Applications

- High-end road bicycles

- Mountain bike builds

- Racing and competition bikes

- Custom bicycle projects

- Bike restoration and upgrades

- Professional cycling team equipment

- Triathlon and time trial bikes

Manufacturing and Processing Capabilities

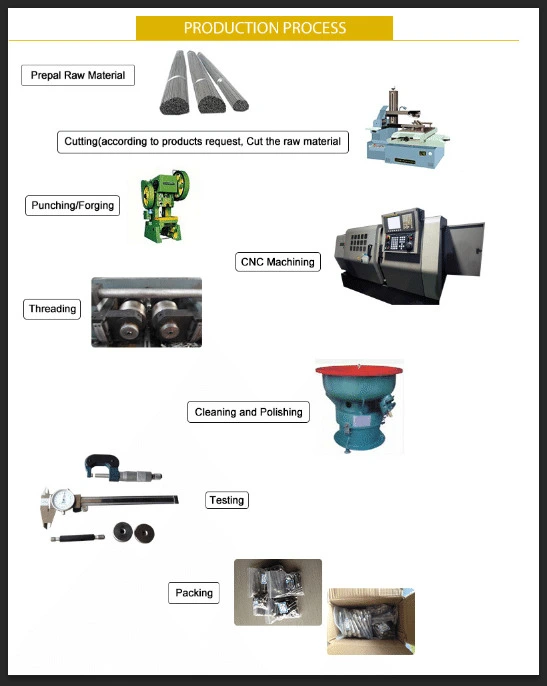

Our state-of-the-art CNC machining centers ensure every screw meets exact specifications. We utilize advanced turning and milling equipment for precise thread cutting and surface finishing. Our experienced technicians monitor each production stage to maintain consistent quality.

Quality control begins with raw material inspection and continues through final packaging. We can accommodate both standard sizes and custom specifications based on your specific derailleur requirements. Our flexible production capabilities handle orders from small quantities to large-scale manufacturing runs.

Production workshop

Production process

Our Services

Custom solutions, fast delivery, competitive pricing, and excellent service.

Titanium Product Manufacturing

Baoji Chuanglian New Metal Material Co., Ltd specializes in manufacturing high-quality titanium and rare metal products. With over ten years of experience, we produce titanium rods, plates, tubes, fasteners, and customized components. Our products meet strict national and international standards, ensuring durability and reliability. We cater to industries such as aerospace, medical, and petrochemical, providing high-performance titanium solutions tailored to customer needs.

Precision Titanium Machining

Equipped with advanced CNC machines, we offer precision machining services, including cutting, milling, drilling, and turning. Our experienced technicians ensure high accuracy and quality in every component. By continuously upgrading our technology, we meet complex machining demands for various industries. Whether you need standard titanium parts or custom-designed solutions, we provide efficient and reliable services.

Strict Quality Control

We maintain a rigorous quality control system from raw material selection to final inspection. Every product undergoes thorough testing to ensure superior performance and longevity. Our titanium products have been trusted by global companies for years, earning a reputation for reliability. With strict adherence to quality standards, we guarantee high-quality products with on-time delivery.

Global Titanium Solutions

Serving industries worldwide, we provide professional titanium solutions, from production to after-sales support. Our products are widely used in aerospace, medical, marine, and industrial fields. We focus on customer satisfaction, offering customized services and technical assistance. With a commitment to innovation and quality, we strive to build long-term partnerships and deliver high-value titanium products globally.

Be used in a wide range of industries.

Automotive Industry

Electronics Industry

Aerospace Industry

Medical Industry

Cars and Racing

Consumer Electronics

Why Choose Us?

Decades of Expertise

With over 10 years of experience, we deliver precise, high-quality titanium products tailored to industry standards.

Customized Solutions

We provide customized titanium solutions to meet your specific needs, ensuring optimal performance and satisfaction.

Advanced Technology

Our cutting-edge machinery ensures precise manufacturing, offering innovative and reliable titanium solutions.

Global Support

We offer excellent customer service, fast delivery, and reliable after-sales support worldwide.

Quality Assurance

We implement comprehensive quality control throughout the manufacturing process. Each batch undergoes dimensional inspection, surface quality checks, and mechanical property testing. Our quality system ensures every Rear Derailleur Titanium Screw meets stringent performance standards.

Material certification accompanies each shipment, providing complete traceability. Our testing procedures verify thread pitch accuracy, surface finish quality, and dimensional conformity. This rigorous approach guarantees consistent performance across all products.

Packaging and Logistics

Your screws arrive safely packed in anti-static bags with protective cushioning. We use moisture-resistant packaging to prevent any environmental damage during shipping. Clear labeling identifies specifications and quantities for easy inventory management.

Fast shipping options ensure prompt delivery worldwide. We work with reliable logistics partners to minimize transit times while maintaining cost-effectiveness. Tracking information keeps you informed throughout the delivery process.

FAQ

Q: What makes titanium better than steel for derailleur screws?

A: Titanium offers superior corrosion resistance, lighter weight, and comparable strength to steel, making it ideal for high-performance cycling applications.

Q: Can these screws fit all derailleur brands?

A: We manufacture custom specifications to match various derailleur models. Contact us with your specific requirements for compatibility confirmation.

Q: How do I choose the right color option?

A: Color selection is purely aesthetic and doesn't affect performance. Choose based on your bike's color scheme or personal preference.

Q: What's the expected lifespan of these screws?

A: With proper installation and normal use, our titanium screws can last the lifetime of your derailleur system.

Why Choose Us

Baoji Chuanglian New Metal Material Co., Ltd. brings over ten years of titanium manufacturing expertise to every product. Located in China's "City of Titanium," we have direct access to premium raw materials and specialized manufacturing knowledge.

Our commitment to quality means you receive components that perform reliably in demanding conditions. We understand cycling enthusiasts need dependable parts that enhance rather than compromise performance. Our global customer base trusts us for consistent quality and professional service.

Competitive pricing doesn't mean compromising on quality. We maintain efficient production processes that deliver value while meeting international standards. Your satisfaction drives our continuous improvement efforts.

Contact Us

Ready to upgrade your bike with premium titanium components? Contact our expert team for technical specifications, custom orders, or product questions.

Email: info@cltifastener.com / djy6580@aliyun.com

We're here to help you find the perfect titanium solution for your cycling needs. Whether you need standard sizes or custom specifications, our team provides professional guidance and fast response times.

Learn about our latest products and discounts through SMS or email