- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

anodized titanium bolts

Material: Titanium alloy

Grade:Gr5(Ti6al4v)

Processing:CNC machined

Surface Treatment: Polishing,Anodizing, Nitriding

Color:Ti nature,Gold,Blue,Green,Purple,Black,Rainbow

Advantage:light, acid and alkali resistance, anti-corrosion, excellent mechanical strength etc.

Anodized Titanium Bolts – Durable, Lightweight, and Corrosion-Resistant

Product Introduction

Anodized titanium bolts are known for their exceptional strength, lightweight properties, and impressive corrosion resistance. These bolts are made from high-quality titanium, which is anodized to enhance its natural resistance to corrosion, making them ideal for use in demanding industries such as aerospace, medical, and marine engineering. Whether you're in need of fasteners for aerospace applications or components for offshore structures, anodized titanium bolts provide the durability and performance you require.

Technical Specifications

| Specification | Description |

|---|---|

| Material | Grade 5 Titanium (Ti-6Al-4V) |

| Finish | Anodized |

| Size Range | M3 to M100 (custom sizes available) |

| Thread Type | Metric, UNC, UNF |

| Corrosion Resistance | Excellent resistance to saltwater, chemicals, and high-temperature environments |

| Temperature Resistance | Up to 600°C |

| Tensile Strength | 130,000 psi |

| Surface Hardness | Up to 400 Vickers |

Product Features (Key Features)

- Lightweight and High Strength: Titanium is renowned for its strength-to-weight ratio, making these bolts ideal for high-performance applications.

- Corrosion Resistance: The anodized surface increases the titanium’s resistance to corrosion, ensuring long-lasting performance in challenging environments.

- Biocompatibility: Anodized titanium is non-reactive and safe for medical applications, including implants and surgical instruments.

- Customizable: Available in various sizes, finishes, and thread types to suit your specific needs.

- Sustainable: Made from environmentally responsible titanium, which is recyclable and has a low environmental impact.

Applications

- Aerospace and Aviation: Ideal for aircraft components that require lightweight, strong, and corrosion-resistant fasteners.

- Medical Devices: Used in implants, surgical instruments, and prosthetics due to their biocompatibility.

- Chemical Processing: Perfect for environments with harsh chemicals, where other materials may corrode.

- Marine Engineering: Provides resistance to saltwater corrosion, making it ideal for offshore structures and shipbuilding.

- Industrial Manufacturing: Suitable for high-performance machinery and tools that require durable and reliable fasteners.

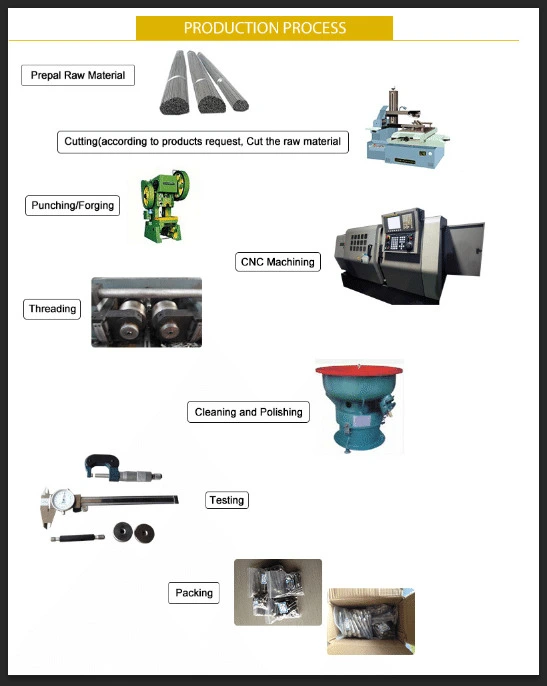

Manufacturing Process

Anodized titanium bolts are manufactured using state-of-the-art CNC machining equipment. After the titanium bolts are produced, they undergo an anodization process to enhance the material’s natural oxide layer, making it more resistant to corrosion and wear. The anodization process also allows for color customization, which can be beneficial for identification purposes in complex systems.

Production workshop

Production process

Our Services

Custom solutions, fast delivery, competitive pricing, and excellent service.

Titanium Product Manufacturing

Baoji Chuanglian New Metal Material Co., Ltd specializes in manufacturing high-quality titanium and rare metal products. With over ten years of experience, we produce titanium rods, plates, tubes, fasteners, and customized components. Our products meet strict national and international standards, ensuring durability and reliability. We cater to industries such as aerospace, medical, and petrochemical, providing high-performance titanium solutions tailored to customer needs.

Precision Titanium Machining

Equipped with advanced CNC machines, we offer precision machining services, including cutting, milling, drilling, and turning. Our experienced technicians ensure high accuracy and quality in every component. By continuously upgrading our technology, we meet complex machining demands for various industries. Whether you need standard titanium parts or custom-designed solutions, we provide efficient and reliable services.

Strict Quality Control

We maintain a rigorous quality control system from raw material selection to final inspection. Every product undergoes thorough testing to ensure superior performance and longevity. Our titanium products have been trusted by global companies for years, earning a reputation for reliability. With strict adherence to quality standards, we guarantee high-quality products with on-time delivery.

Global Titanium Solutions

Serving industries worldwide, we provide professional titanium solutions, from production to after-sales support. Our products are widely used in aerospace, medical, marine, and industrial fields. We focus on customer satisfaction, offering customized services and technical assistance. With a commitment to innovation and quality, we strive to build long-term partnerships and deliver high-value titanium products globally.

Be used in a wide range of industries.

Automotive Industry

Electronics Industry

Aerospace Industry

Medical Industry

Cars and Racing

Consumer Electronics

Why Choose Us?

Decades of Expertise

With over 10 years of experience, we deliver precise, high-quality titanium products tailored to industry standards.

Customized Solutions

We provide customized titanium solutions to meet your specific needs, ensuring optimal performance and satisfaction.

Advanced Technology

Our cutting-edge machinery ensures precise manufacturing, offering innovative and reliable titanium solutions.

Global Support

We offer excellent customer service, fast delivery, and reliable after-sales support worldwide.

Quality Assurance

At Baoji Chuanglian New Metal Material Co., Ltd., quality is paramount. Each batch of anodized titanium bolts undergoes strict quality control measures, from raw material inspection to final product testing. Our quality assurance process includes tensile strength testing, corrosion resistance testing, and dimensional checks to ensure that every product meets the highest standards.

Packaging and Logistics

We offer secure packaging solutions to protect your anodized titanium bolts during shipping. Our logistics team ensures timely delivery to any location, whether you are in North America, Europe, or Asia-Pacific. We provide both bulk and customized packaging to suit your needs.

Customer Support

Our dedicated customer support team is available to assist you with any inquiries you may have. Whether you need technical advice, help with customizing your order, or information about pricing and delivery, we are here to help. Reach out to us via email at info@cltifastener.com or by phone at +8613571186580.

Why Choose Us

- Experienced Manufacturer: With over a decade of expertise in titanium machining and anodizing, we are a trusted supplier for industries worldwide.

- Reliable Supply: We offer consistent delivery, ensuring you receive your orders on time without delay.

- Customized Solutions: We can tailor anodized titanium bolts to your specifications, including size, finish, and threading.

- Competitive Pricing: We provide high-quality products at competitive prices, making us an excellent choice for both large enterprises and SMEs.

- Global Reach: Serving clients across North America, Europe, Asia, and the Middle East, we are your global partner for titanium solutions.

OEM Services

We offer OEM services to meet your specific requirements, including custom sizes, finishes, and threading options. Whether you need small batches or large-volume orders, our flexible manufacturing capabilities ensure that we can provide exactly what you need.

Frequently Asked Questions (FAQs)

-

What industries use anodized titanium bolts? Anodized titanium bolts are commonly used in aerospace, medical devices, chemical processing, marine engineering, and industrial manufacturing.

-

What makes anodized titanium bolts superior to other materials? Titanium is strong, lightweight, and resistant to corrosion, making anodized titanium bolts ideal for use in challenging environments where other materials may fail.

-

Can I order custom sizes of anodized titanium bolts? Yes, we offer custom sizes, finishes, and threading to suit your specific needs.

-

How can I ensure the quality of the bolts? We adhere to strict quality control procedures to ensure that every batch of anodized titanium bolts meets international standards.

Contact Details

For inquiries or to place an order, please contact us at:

- Email: info@cltifastener.com

- Phone: +8613571186580

With our commitment to quality, customer service, and innovation, Baoji Chuanglian New Metal Material Co., Ltd. is your trusted partner for anodized titanium bolts and other titanium products. Reach out to us today to discover how we can support your business!

Learn about our latest products and discounts through SMS or email