- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

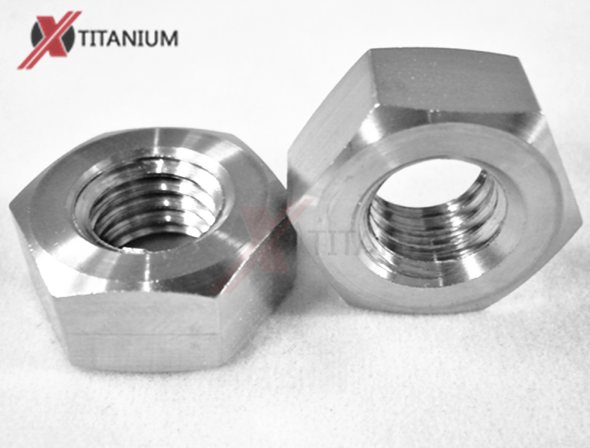

titanium lug bolts

Material: Titanium alloy

Grade:Gr5(Ti6al4v)

Processing:CNC machined

Surface Treatment: Polishing,Anodizing, Nitriding

Color:Ti nature,Gold,Blue,Green,Purple,Black,Rainbow

Advantage:light, acid and alkali resistance, anti-corrosion, excellent mechanical strength etc.

Titanium Lug Bolts: High-Performance Fastening Solutions for Automotive and Industrial Applications

Introduction to Titanium Lug Bolts

Titanium lug bolts are advanced fastening components specifically designed for high-performance applications in automotive, aerospace, and industrial sectors. These bolts offer a superior strength-to-weight ratio, corrosion resistance, and exceptional durability compared to traditional steel or aluminum fasteners. Titanium's lightweight properties significantly reduce unsprung weight in vehicles, leading to improved handling and fuel efficiency.

Manufactured using precision machining and strict quality control standards, titanium lug bolts are widely used in motorsports, luxury vehicles, and heavy-duty machinery that require high-performance fastening solutions. Due to their excellent thermal stability and resistance to environmental factors such as moisture, chemicals, and extreme temperatures, these bolts ensure long-lasting performance in demanding conditions.

Product Standards and Specifications

1.0 Product Identification & Scope

The standards and specifications for high-performance titanium lug bolts intended for automotive, motorcycle, and racing applications. These fasteners are designed to secure wheels to hubs, offering a superior strength-to-weight ratio compared to standard steel bolts.

2.0 Material Specifications

· Base Material: Aerospace-grade titanium alloy, typically Ti-6Al-4V (Grade 5) or equivalent.

· Material Standards: Must conform to ASTM B348 (Grade 5), AMS 4928, or equivalent internationally recognized standards.

· Certification: Mill certificates (C of C) verifying alloy composition and mechanical properties are required for each batch.

3.0 Mechanical & Performance Properties

· Tensile Strength: ≥ 900 MPa (130 ksi) minimum.

· Yield Strength (0.2% Offset): ≥ 830 MPa (120 ksi) minimum.

· Elongation: ≥ 10% minimum.

· Hardness: 32-38 HRC (Rockwell C Scale).

· Fatigue Strength: High-cycle fatigue performance must be validated per relevant testing protocols (e.g., SAE J 1349 or internal dynamic load simulation).

· Shear Strength: Must be specified and tested for relevant bolt sizes and designs.

4.0 Dimensional & Geometric Specifications

· Thread Pitch & Profile: Must conform to ISO Metric (e.g., M12 x 1.5) or relevant SAE (e.g., 1/2"-20) standards as specified. Threads to ANSI/ASME B1.13M or B1.1 standards (Class 6g or 6H tolerance).

· Head Style: As per design—typically conical seat (e.g., 60° taper), ball seat, or flat seat with washer.

· Drive Type: Hex socket (Allen), splined drive, or hex head, to specified dimensions and tolerances.

· Length: Measured from under-head to bolt tip, to customer-specified dimensions with a standard tolerance of ±0.25mm.

· Surface Finish: All surfaces must be free of burrs, cracks, or machining defects. Threads must be clean and precise.

5.0 Surface Treatment & Coatings

· Primary Treatment: Anodization is mandatory to prevent galling (cold welding) and provide a durable, corrosion-resistant surface.

· Type: Hard coat anodization per MIL-A-8625 Type III or equivalent.

· Thickness: 25-50 microns (0.001"-0.002").

· Color: Typically silver, black, or other specified colors.

· Alternative/Supplementary Coatings: Dry film lubricants (e.g., PTFE-based) or specialized anti-seize coatings may be applied to threads to ensure consistent and accurate clamping force (torque).

Basic Parameters

The following table presents the fundamental technical specifications of titanium lug bolts:

| Parameter | Specification |

|---|---|

| Material | Titanium Grade 5 (Ti-6Al-4V) |

| Tensile Strength | ≥ 950 MPa (Grade 5) |

| Yield Strength | ≥ 880 MPa (Grade 5) |

| Hardness | Rockwell C35 (Grade 5) |

| Density | 4.51 g/cm³ |

| Melting Point | 1,668°C |

| Thread Type | Metric (M12, M14, M16), Custom Sizes Available |

| Surface Treatment | Polished, Anodized, PVD Coating |

| Weight Reduction | Up to 50% lighter than steel |

Product Attributes and Functions

Titanium lug bolts are designed for high-strength applications, offering a range of features that enhance their mechanical and physical performance:

Corrosion Resistance: Resistant to oxidation, rust, and chemical exposure.

Lightweight Construction: Reduces vehicle weight, improving fuel efficiency and performance.

High Temperature Resistance: Maintains mechanical properties under extreme heat conditions.

Biocompatibility: Suitable for medical applications and sensitive environments.

High Strength-to-Weight Ratio: Provides exceptional load-bearing capacity without excessive mass.

Product Features and Advantages

| Feature | Benefit |

| Aerospace-Grade Titanium | Ensures superior strength and durability |

| Precision Machining | Provides exact fit and compatibility |

| Custom Finishes | Anodized and PVD coatings for enhanced aesthetics and protection |

| Rust-Proof Design | Ideal for wet, saline, and harsh environments |

| Thread Accuracy | Ensures secure installation and torque control |

| Lightweight | Improves handling, acceleration, and efficiency in vehicles |

Applications of Titanium Lug Bolts

1. Motorsports & High-Performance Racing

This is the most common and critical application. The benefits are directly measurable on the track.

2. High-End Automotive & Track-Day Enthusiast Vehicles

Owners of sports cars (e.g., Porsche, Corvette, BMW M-series) and supercars seeking to optimize performance.

3. Motorcycle & Bicycle Racing

4. Aerospace & Aviation Ground Support

· Lightweighting for Flight: Used on aircraft wheels and critical components where reducing mass is directly tied to fuel efficiency and performance.

· Corrosion Resistance: Essential for resisting harsh aviation environments and de-icing fluids.

5. Premium Commercial & Military Applications

· High-Value Vehicles: Used in luxury RVs, performance trucks, and specialty military vehicles where a combination of durability, light weight, and corrosion resistance is valued.

· Marine Environments: On support vehicles or equipment exposed to saltwater, titanium's near-complete immunity to salt corrosion makes it an excellent, albeit expensive, choice.

6. Critical Industrial & Engineering Applications

Quality Assurance & Testing

· Dimensional Inspection: 100% inspection of critical dimensions (thread pitch, major diameter, seat angle, length).

· Material Verification: Spectrographic analysis to confirm alloy composition.

· Mechanical Testing: Batch testing for tensile, yield, and hardness properties.

· Torque-to-Yield Testing: Sample testing to verify performance under specified installation torque.

· Visual & Surface Inspection: 100% inspection for surface defects and coating consistency.

· Certification: Each shipment must be accompanied by a Certificate of Conformance (CoC) detailing material grade, mechanical test results, and compliance with this specification.

Marking & Packaging

· Marking: Each bolt must be permanently marked with:

· Manufacturer's logo or identifier.

· Material Grade (e.g., "Ti-6Al-4V" or "GR5").

· Strength Grade marking (if applicable).

· Packaging: Bolts must be packaged to prevent in-transit damage and corrosion. Packaging should clearly state part number, quantity, material, and specifications.

Safety & Usage Specifications

· Torque Specifications: Must be installed using a calibrated torque wrench. Manufacturer-provided torque values are critical and must not exceed. Anti-seize compound use must align with coating specifications to avoid over-torquing.

· Application: Designed for performance use. Periodic inspection for wear, damage, or corrosion is mandatory. Not recommended for indefinite use; recommended service life should be specified by the manufacturer.

· Warning: Titanium bolts are not interchangeable with steel bolts without recalculating appropriate torque settings and verifying seat compatibility.

OEM Services and Customization

Baoji Chuanglian New Metal Material Co., Ltd. specializes in the production and supply of titanium lug bolts with extensive OEM services. We provide:

Custom Dimensions & Thread Designs: Tailored to client specifications.

Special Coatings: Anodizing, DLC (Diamond-Like Carbon), and PVD coatings.

Precision Engineering: High-tolerance machining for exact fitment.

Bulk Orders & Fast Delivery: Efficient supply chain management to meet large-volume demands.

Frequently Asked Questions (FAQs)

Why choose titanium lug bolts over steel bolts? Titanium lug bolts are significantly lighter, stronger, and more corrosion-resistant than steel, making them ideal for high-performance applications.

Are titanium lug bolts compatible with all wheel types? Yes, they are available in various thread sizes and head designs to ensure compatibility with different wheel types.

Do titanium bolts require special tools for installation? No, standard installation tools can be used, but proper torque specifications should be followed.

Can titanium lug bolts withstand high temperatures? Yes, they maintain structural integrity under extreme heat, making them suitable for motorsports and aerospace applications.

Do you offer custom titanium fasteners? Yes, we provide fully customizable solutions based on customer requirements.

Baoji Chuanglian New Metal Material Co., Ltd. is a professional manufacturer and supplier of titanium lug bolts. We offer high-quality, certified titanium fasteners with complete test reports, OEM support, fast delivery, and secure packaging. If you need premium titanium fasteners, contact us at info@cltifastener.com / djy6580@aliyun.com for expert solutions and quotations.

Learn about our latest products and discounts through SMS or email