- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

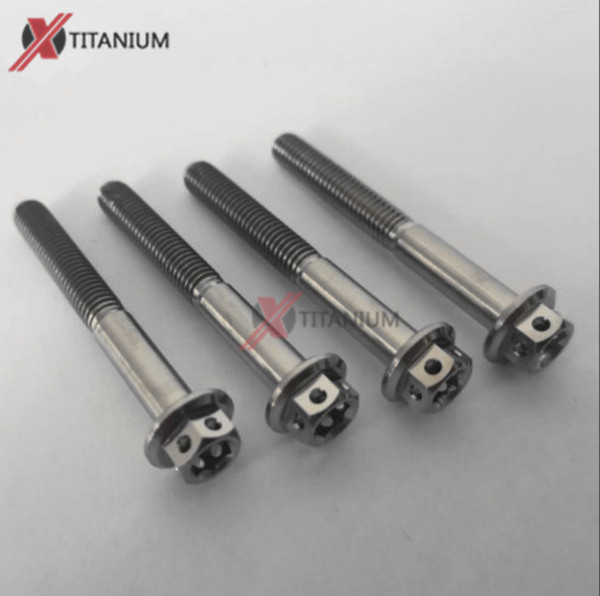

titanium forged fittings

Surface:Bright, Polished, Pickling, Acid cleaning, Sandblasting

Quality and test:Hardness test, Bending test, Hydrostatic etc.

Feature:High corrosion resistance, low density, good thermal stability

Application:Chemical, industry, sports etc.

Titanium Forged Fittings – Premium Quality for High-Performance Industries

Product Introduction

Titanium forged fittings are essential components in industries requiring high strength, durability, and resistance to harsh environments. Made from high-grade titanium, these fittings offer unparalleled performance in applications where corrosion resistance, lightweight, and strength are crucial. Baoji Chuanglian New Metal Material Co., Ltd. offers a wide range of titanium forged fittings that meet the highest industry standards and provide reliable, long-lasting solutions for demanding applications in aerospace, marine engineering, medical devices, and more.

Technical Specifications

| Specification | Value |

|---|---|

| Material | Titanium Grade 2, Grade 5, and others |

| Surface Finish | Polished, Sandblasted, or Customized |

| Temperature Range | Up to 600°C |

| Standard | ASTM B564, ASTM F136, ISO 5832-3 |

| Sizes Available | Customizable based on requirements |

| Pressure Ratings | High Pressure Options Available |

Product Features (Key Features)

- Corrosion Resistance: Titanium’s excellent resistance to corrosion makes these fittings ideal for marine, chemical, and medical industries.

- Lightweight: Titanium is approximately 45% lighter than steel, ensuring reduced weight in applications like aerospace and automotive.

- Strength and Durability: Offers exceptional tensile strength and impact resistance, making titanium forged fittings a reliable choice for demanding environments.

- High Temperature Resistance: Suitable for high-temperature environments like chemical processing and aerospace applications.

- Biocompatibility: Non-toxic and compatible with the human body, making it ideal for medical applications, including implants and prosthetics.

- Customization Options: Tailor the size, shape, and finish of your fittings to suit your exact needs.

Applications

Titanium forged fittings are widely used across several high-performance industries, including:

- Aerospace: For manufacturing lightweight, high-strength components in aircraft and spacecraft.

- Medical Devices: Biocompatible fittings used in surgical instruments, implants, and prosthetics.

- Chemical Processing: Corrosion-resistant fittings used in reactors, pipes, and storage tanks.

- Energy Sector: Fittings for nuclear power plants, wind turbines, and solar energy systems.

- Marine Engineering: For offshore structures and shipbuilding due to titanium’s resistance to saltwater corrosion.

- Industrial Manufacturing: Durable, high-strength fittings used in machinery, tools, and fasteners.

Manufacturing Process

Our titanium forged fittings are produced using advanced forging and machining techniques. The process includes:

- Material Selection: Only premium-grade titanium is selected to ensure quality and performance.

- Forging: The titanium is heated to high temperatures and shaped using high-pressure forging techniques to achieve optimal strength and durability.

- Machining: The forged components are then precisely machined to the required specifications.

- Surface Finishing: Options for polished, sandblasted, or customized surface finishes are available to meet specific requirements.

- Quality Control: Every fitting undergoes stringent quality checks to ensure that it meets industry standards.

Production workshop

Our Services

Custom solutions, fast delivery, competitive pricing, and excellent service.

Titanium Product Manufacturing

Baoji Chuanglian New Metal Material Co., Ltd specializes in manufacturing high-quality titanium and rare metal products. With over ten years of experience, we produce titanium rods, plates, tubes, fasteners, and customized components. Our products meet strict national and international standards, ensuring durability and reliability. We cater to industries such as aerospace, medical, and petrochemical, providing high-performance titanium solutions tailored to customer needs.

Precision Titanium Machining

Equipped with advanced CNC machines, we offer precision machining services, including cutting, milling, drilling, and turning. Our experienced technicians ensure high accuracy and quality in every component. By continuously upgrading our technology, we meet complex machining demands for various industries. Whether you need standard titanium parts or custom-designed solutions, we provide efficient and reliable services.

Strict Quality Control

We maintain a rigorous quality control system from raw material selection to final inspection. Every product undergoes thorough testing to ensure superior performance and longevity. Our titanium products have been trusted by global companies for years, earning a reputation for reliability. With strict adherence to quality standards, we guarantee high-quality products with on-time delivery.

Global Titanium Solutions

Serving industries worldwide, we provide professional titanium solutions, from production to after-sales support. Our products are widely used in aerospace, medical, marine, and industrial fields. We focus on customer satisfaction, offering customized services and technical assistance. With a commitment to innovation and quality, we strive to build long-term partnerships and deliver high-value titanium products globally.

Be used in a wide range of industries.

Automotive Industry

Electronics Industry

Aerospace Industry

Medical Industry

Cars and Racing

Consumer Electronics

Why Choose Us?

Decades of Expertise

With over 10 years of experience, we deliver precise, high-quality titanium products tailored to industry standards.

Customized Solutions

We provide customized titanium solutions to meet your specific needs, ensuring optimal performance and satisfaction.

Advanced Technology

Our cutting-edge machinery ensures precise manufacturing, offering innovative and reliable titanium solutions.

Global Support

We offer excellent customer service, fast delivery, and reliable after-sales support worldwide.

Quality Assurance

At Baoji Chuanglian New Metal Material Co., Ltd., we adhere to strict quality control standards. From raw material inspection to final product testing, every step of the manufacturing process is closely monitored to ensure our titanium forged fittings meet international standards such as ASTM, ISO, and AMS. We pride ourselves on delivering high-quality, reliable products that exceed customer expectations.

Packaging and Logistics

We take great care in packaging our titanium forged fittings to ensure they arrive at your location in perfect condition. Our packaging includes:

- Custom Packaging: Tailored to the size and weight of the fittings to ensure safe transportation.

- Secure Shipping: Fittings are shipped using trusted logistics providers to guarantee timely delivery worldwide.

- Tracking: We provide tracking numbers so you can monitor your order's progress.

Customer Support

Our dedicated customer support team is always available to assist you with inquiries, order tracking, and technical support. Whether you need help with product selection or have questions about our manufacturing process, we are here to help. You can reach us at:

- Email: info@cltifastener.com

- Phone: +8613571186580

Why Choose Us?

- Expertise: With over 10 years of experience in titanium machining, we understand the unique demands of different industries.

- Global Reach: We serve customers around the world, ensuring consistent quality and timely delivery.

- Custom Solutions: We offer tailored solutions to meet your specific requirements, from material selection to final product specifications.

- Competitive Pricing: We provide high-quality titanium forged fittings at competitive prices, ensuring cost-efficiency for large and small orders alike.

OEM Services

We provide OEM services to cater to your custom titanium forged fitting needs. Our expert team works closely with you to develop solutions that meet your specific requirements. Whether you need bespoke sizes, finishes, or packaging, we are here to deliver.

Frequently Asked Questions (FAQs)

1. What is the lead time for titanium forged fittings?

Our typical lead time is between 7 to 30 days, depending on the complexity of the order and customization required.

2. Can you provide titanium forged fittings in custom sizes?

Yes, we offer custom manufacturing services for titanium forged fittings to meet your exact specifications.

3. Are the titanium forged fittings suitable for high-pressure applications?

Yes, our fittings are designed to withstand high-pressure environments, including those found in the aerospace and energy sectors.

4. How do you ensure the quality of your products?

We adhere to strict quality control standards, including testing against industry benchmarks and performing rigorous inspections at each production stage.

Contact Details

For inquiries or to place an order, feel free to contact us:

- Email: info@cltifastener.com

- Phone: +8613571186580

We look forward to providing you with high-quality titanium forged fittings and reliable service. Reach out today!

Learn about our latest products and discounts through SMS or email