- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Customized Titanium Flange Nuts M10X1.25

Material: Pure titanium,Titanium alloy

Grade:Gr2,Gr5(Ti6al4v)

Processing:CNC machined

Surface Treatment: Polishing,Anodizing, Nitriding

Color:Ti nature,Gold,Blue,Green,Purple,Black,Rainbow

Advantage:light, acid and alkali resistance, anti-corrosion, excellent mechanical strength etc.

Customized Titanium Flange Nuts M10X1.25 - Premium Precision Fasteners

Product Introduction

Looking for reliable, high-performance fastening solutions? Our Customized Titanium Flange Nuts M10X1.25 deliver exceptional strength and corrosion resistance for your most demanding applications. Made from premium titanium materials, these precision-engineered flange nuts offer superior performance compared to traditional steel fasteners. Whether you need standard specifications or custom modifications, we provide exactly what your project requires. Our titanium flange nuts combine lightweight design with outstanding mechanical properties, making them ideal for aerospace, marine, and industrial applications where weight reduction and durability matter most.

At Baoji Chuanglian New Metal Material Co., Ltd., we specialize in manufacturing high-quality titanium fasteners that meet the strictest industry standards. With over ten years of expertise in titanium processing, we understand what it takes to create fasteners that perform reliably in challenging environments.

Technical Specifications

| Parameter | Specification |

|---|---|

| Thread Size | M10X1.25 |

| Material | Pure Titanium, Titanium Alloy |

| Grade | Gr2,Gr5 (Ti6Al4V) |

| Standard | Customized |

| Processing Method | CNC Machined |

| Surface Treatment | Polishing, Anodizing, Nitriding |

| Available Colors | Natural Titanium, Gold, Blue, Green, Purple, Black, Rainbow |

| Tolerance | ±0.05mm |

| Thread Type | Metric Fine Thread |

| Flange Style | Integrated Design |

Key Features

Lightweight Excellence: Our titanium flange nuts weigh 40% less than steel equivalents while maintaining superior strength. This weight reduction translates to improved fuel efficiency in aerospace applications and easier handling during assembly.

Exceptional Corrosion Resistance: Titanium's natural oxide layer provides outstanding protection against saltwater, acids, and harsh chemicals. Your fasteners will maintain their integrity even in the most corrosive environments.

High Temperature Performance: These nuts perform reliably in temperature ranges from -200°C to +600°C, making them suitable for extreme operating conditions.

Precision Manufacturing: Every nut is CNC machined to exact specifications, ensuring perfect thread engagement and consistent performance across your entire order.

Product Characteristics

Our titanium flange nuts offer unique advantages that set them apart from conventional fasteners. The integrated flange design eliminates the need for separate washers, reducing assembly time and part count. The biocompatible properties of titanium make these fasteners safe for medical device applications.

The fine M10X1.25 thread pitch provides superior clamping force distribution, reducing stress concentrations that can lead to failure. Surface treatments can be customized to meet specific requirements, from enhanced wear resistance to improved aesthetics.

Customized Titanium Flange Nuts M10X1.25 maintain their mechanical properties even after extended exposure to UV radiation, making them perfect for outdoor applications where other materials might degrade.

Applications

Aerospace Industry: Landing gear assemblies, engine components, and structural connections where weight savings are critical.

Marine Engineering: Boat hardware, offshore platforms, and underwater equipment that must resist saltwater corrosion.

Medical Devices: Surgical instruments, implantable devices, and diagnostic equipment requiring biocompatible materials.

Automotive Racing: High-performance vehicles where every gram matters and reliability is non-negotiable.

Chemical Processing: Equipment exposed to corrosive chemicals where standard fasteners would fail prematurely.

Renewable Energy: Wind turbine components and solar panel mounting systems requiring long-term durability.

Manufacturing and Processing Capabilities

Our state-of-the-art manufacturing facility houses advanced CNC machining centers capable of producing complex geometries with exceptional precision. We maintain strict temperature and humidity controls throughout the production process to ensure consistent quality.

Quality starts with raw material selection. We source only certified titanium from reputable suppliers, with full traceability documentation. Our experienced machinists undergo continuous training to stay current with the latest techniques and quality standards.

Secondary operations like anodizing and surface treatments are performed in-house, giving us complete control over the final product quality and delivery schedule.

Production workshop

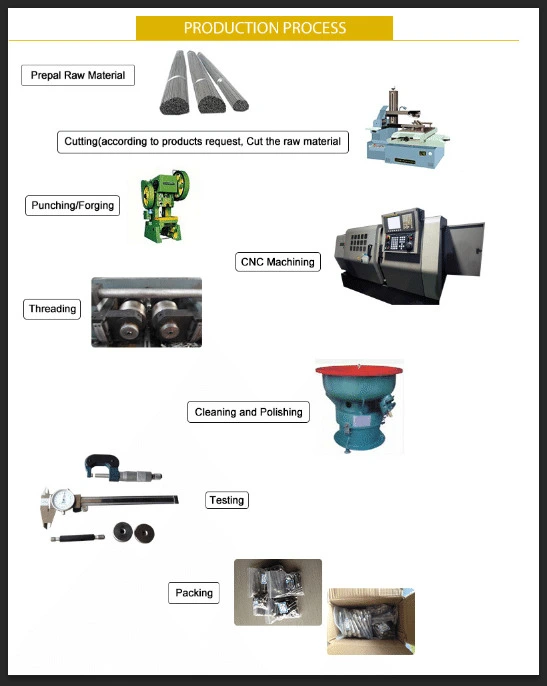

Production process

Our Services

Custom solutions, fast delivery, competitive pricing, and excellent service.

Titanium Product Manufacturing

Baoji Chuanglian New Metal Material Co., Ltd specializes in manufacturing high-quality titanium and rare metal products. With over ten years of experience, we produce titanium rods, plates, tubes, fasteners, and customized components. Our products meet strict national and international standards, ensuring durability and reliability. We cater to industries such as aerospace, medical, and petrochemical, providing high-performance titanium solutions tailored to customer needs.

Precision Titanium Machining

Equipped with advanced CNC machines, we offer precision machining services, including cutting, milling, drilling, and turning. Our experienced technicians ensure high accuracy and quality in every component. By continuously upgrading our technology, we meet complex machining demands for various industries. Whether you need standard titanium parts or custom-designed solutions, we provide efficient and reliable services.

Strict Quality Control

We maintain a rigorous quality control system from raw material selection to final inspection. Every product undergoes thorough testing to ensure superior performance and longevity. Our titanium products have been trusted by global companies for years, earning a reputation for reliability. With strict adherence to quality standards, we guarantee high-quality products with on-time delivery.

Global Titanium Solutions

Serving industries worldwide, we provide professional titanium solutions, from production to after-sales support. Our products are widely used in aerospace, medical, marine, and industrial fields. We focus on customer satisfaction, offering customized services and technical assistance. With a commitment to innovation and quality, we strive to build long-term partnerships and deliver high-value titanium products globally.

Be used in a wide range of industries.

Automotive Industry

Electronics Industry

Aerospace Industry

Medical Industry

Cars and Racing

Consumer Electronics

Why Choose Us?

Decades of Expertise

With over 10 years of experience, we deliver precise, high-quality titanium products tailored to industry standards.

Customized Solutions

We provide customized titanium solutions to meet your specific needs, ensuring optimal performance and satisfaction.

Advanced Technology

Our cutting-edge machinery ensures precise manufacturing, offering innovative and reliable titanium solutions.

Global Support

We offer excellent customer service, fast delivery, and reliable after-sales support worldwide.

Quality Assurance

Every batch of Customized Titanium Flange Nuts M10X1.25 undergoes comprehensive testing including dimensional inspection, thread gauge verification, and material composition analysis. We maintain detailed quality records for complete traceability.

Our quality management system ensures consistent output that meets or exceeds customer expectations. From incoming material inspection to final packaging, every step is carefully monitored and documented.

We perform regular equipment calibration and maintenance to maintain the highest manufacturing standards. Customer satisfaction is our top priority, and we stand behind every product we manufacture.

Packaging and Logistics

We protect your investment with careful packaging designed to prevent damage during shipping. Each order is individually packaged with protective materials and clear labeling for easy identification.

Standard packaging includes moisture barriers to prevent oxidation and foam cushioning to prevent mechanical damage. Custom packaging solutions are available for special requirements or sensitive applications.

Our logistics team coordinates with reliable shipping partners to ensure timely delivery anywhere in the world. We provide tracking information and delivery confirmation for every shipment.

FAQ

Q: What makes titanium better than stainless steel for flange nuts?

A: Titanium offers superior strength-to-weight ratio, better corrosion resistance, and excellent biocompatibility. It's particularly advantageous in aerospace, marine, and medical applications.

Q: Can you modify the thread pitch or flange diameter?

A: Yes, we specialize in custom modifications. Our engineering team can work with your specifications to create exactly what you need.

Q: What surface treatments do you recommend for marine applications?

A: For marine environments, we typically recommend anodizing for additional corrosion protection and improved wear resistance.

Q: Do you provide material certificates?

A: Yes, we provide complete material traceability documentation including composition analysis and mechanical property test results.

Why Choose Us

With over a decade of experience in titanium processing, Baoji Chuanglian New Metal Material Co., Ltd. has earned a reputation for excellence in the global fastener market. We combine advanced manufacturing capabilities with personalized service to deliver exactly what you need.

Our location in Baoji City, known as the "City of Titanium," gives us access to the finest raw materials and specialized expertise. We invest continuously in new equipment and technology to maintain our competitive edge.

Customer satisfaction drives everything we do. From initial consultation through final delivery, we're committed to exceeding your expectations with quality products and professional service.

Contact Us

Ready to experience the superior performance of our Customized Titanium Flange Nuts M10X1.25? Contact our technical sales team today to discuss your specific requirements.

Email: info@cltifastener.com / djy6580@aliyun.com

Our knowledgeable staff is ready to help you select the perfect fastening solution for your application. We look forward to partnering with you on your next project.

Learn about our latest products and discounts through SMS or email