- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Gr5 Titanium Nylock 12 Point Flange Nut

Material: Titanium alloy

Grade:Gr5(Ti6al4v)

Processing:CNC machined

Surface Treatment: Polishing,Anodizing, Nitriding

Color:Ti nature,Gold,Blue,Green,Purple,Black,Rainbow

Advantage:light, acid and alkali resistance, anti-corrosion, excellent mechanical strength etc.

Gr5 Titanium Nylock 12 Point Flange Nut

Product Introduction

Looking for superior fastening solutions? Our Gr5 Titanium Nylock 12 Point Flange Nut combines exceptional strength with corrosion resistance. Made from premium titanium alloy Ti6Al4V, this specialized fastener offers outstanding performance in demanding applications. You get the perfect balance of lightweight design and superior mechanical properties. Each nut features a built-in nylon locking mechanism and integrated flange for enhanced distribution of clamping force. Whether you're working in aerospace, marine, or high-performance automotive applications, this titanium fastener delivers reliability you can trust.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | Gr5 Titanium Alloy (Ti6Al4V) |

| Standard | Customized to requirements |

| Thread Type | Metric/Imperial (Custom) |

| Size Range | M6-M20 (or equivalent) |

| Processing Method | CNC Machined |

| Surface Treatment | Polishing, Anodizing, Nitriding |

| Available Colors | Natural Titanium, Gold, Blue, Green, Purple, Black, Rainbow |

| Lock Type | Nylon Insert (Nylock) |

| Flange Design | Integrated 12-point configuration |

| Tensile Strength | ≥895 MPa |

| Operating Temperature | -200°C to +400°C |

Key Features

Superior Locking Mechanism: The nylon insert provides reliable vibration resistance. Your connections stay secure even under extreme conditions.

12-Point Flange Design: Enhanced grip surface allows for precise torque application. You can achieve consistent clamping force every time.

Lightweight Yet Strong: Titanium offers 40% weight reduction compared to steel. You maintain strength while reducing overall assembly weight.

Corrosion Resistant: Excellent resistance to saltwater, acids, and harsh chemicals. Your fasteners last longer in challenging environments.

Multiple Surface Options: Choose from various anodized colors or natural finish. You can match your aesthetic requirements perfectly.

Product Characteristics

Our titanium nuts excel in extreme environments where standard fasteners fail. The Gr5 Titanium Nylock 12 Point Flange Nut maintains its properties across wide temperature ranges. You benefit from consistent performance whether in arctic conditions or high-heat applications.

The precision CNC machining ensures perfect thread engagement. Each nut undergoes strict dimensional control for reliable fit. You can trust these fasteners for critical assemblies where failure is not an option.

The nylon locking insert is specially selected for titanium compatibility. It provides optimal torque retention without thread damage. Your installations remain secure throughout their service life.

Applications

Aerospace Industry: Aircraft structural components, engine assemblies, and avionics mounting systems benefit from the lightweight strength.

Marine Engineering: Boat hardware, offshore equipment, and submarine components resist saltwater corrosion effectively.

Automotive Racing: High-performance vehicles use these nuts for engine components and suspension systems where weight matters.

Medical Equipment: Surgical instruments and implant hardware require biocompatible titanium materials.

Chemical Processing: Equipment exposed to corrosive substances needs titanium's chemical resistance.

Power Generation: Wind turbine components and nuclear applications demand reliable, long-lasting fasteners.

Manufacturing and Processing Capabilities

Our state-of-the-art CNC machining centers ensure precise manufacturing. We maintain tight tolerances across all dimensions. You receive consistent quality in every batch.

Advanced heat treatment processes optimize the titanium's mechanical properties. Our experienced technicians monitor each production step carefully. Quality control begins with raw material inspection and continues through final packaging.

We offer complete customization capabilities. Thread pitch, head dimensions, and flange specifications can be tailored to your needs. Our engineering team works with you to develop optimal solutions.

Production workshop

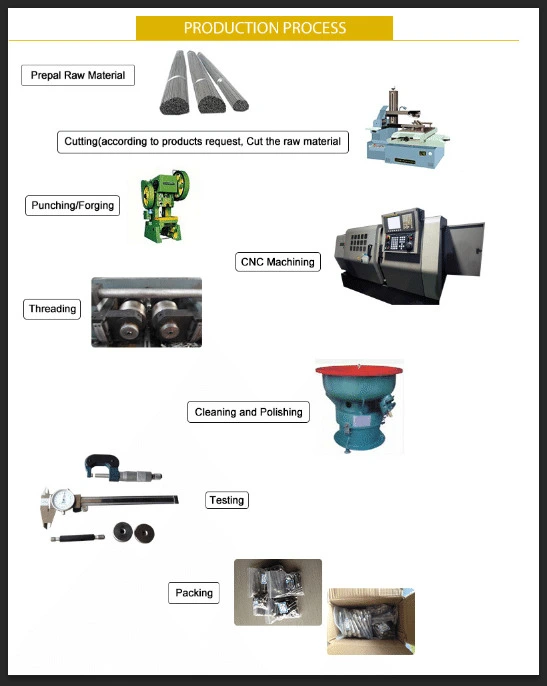

Production process

Our Services

Custom solutions, fast delivery, competitive pricing, and excellent service.

Titanium Product Manufacturing

Baoji Chuanglian New Metal Material Co., Ltd specializes in manufacturing high-quality titanium and rare metal products. With over ten years of experience, we produce titanium rods, plates, tubes, fasteners, and customized components. Our products meet strict national and international standards, ensuring durability and reliability. We cater to industries such as aerospace, medical, and petrochemical, providing high-performance titanium solutions tailored to customer needs.

Precision Titanium Machining

Equipped with advanced CNC machines, we offer precision machining services, including cutting, milling, drilling, and turning. Our experienced technicians ensure high accuracy and quality in every component. By continuously upgrading our technology, we meet complex machining demands for various industries. Whether you need standard titanium parts or custom-designed solutions, we provide efficient and reliable services.

Strict Quality Control

We maintain a rigorous quality control system from raw material selection to final inspection. Every product undergoes thorough testing to ensure superior performance and longevity. Our titanium products have been trusted by global companies for years, earning a reputation for reliability. With strict adherence to quality standards, we guarantee high-quality products with on-time delivery.

Global Titanium Solutions

Serving industries worldwide, we provide professional titanium solutions, from production to after-sales support. Our products are widely used in aerospace, medical, marine, and industrial fields. We focus on customer satisfaction, offering customized services and technical assistance. With a commitment to innovation and quality, we strive to build long-term partnerships and deliver high-value titanium products globally.

Be used in a wide range of industries.

Automotive Industry

Electronics Industry

Aerospace Industry

Medical Industry

Cars and Racing

Consumer Electronics

Why Choose Us?

Decades of Expertise

With over 10 years of experience, we deliver precise, high-quality titanium products tailored to industry standards.

Customized Solutions

We provide customized titanium solutions to meet your specific needs, ensuring optimal performance and satisfaction.

Advanced Technology

Our cutting-edge machinery ensures precise manufacturing, offering innovative and reliable titanium solutions.

Global Support

We offer excellent customer service, fast delivery, and reliable after-sales support worldwide.

Quality Assurance

Every fastener undergoes comprehensive testing before shipment. We verify dimensional accuracy, material composition, and mechanical properties. Our quality system ensures you receive products that meet your specifications.

Material certifications accompany each order. We provide full traceability from raw material source through final inspection. Your quality requirements are our top priority.

Regular equipment calibration maintains measurement accuracy. Our quality team continuously monitors production processes. Any deviation triggers immediate corrective action.

Packaging and Logistics

Products are carefully packaged to prevent damage during transport. We use anti-static materials and protective cushioning. Your order arrives in perfect condition.

Fast worldwide shipping options are available. We work with reliable logistics partners for timely delivery. Tracking information keeps you informed throughout the shipping process.

Custom packaging solutions accommodate special handling requirements. We can provide specific labeling or documentation as needed.

FAQ

Q: What makes titanium better than steel for nuts?

A: Titanium offers superior corrosion resistance and is 40% lighter than steel while maintaining comparable strength.

Q: Can you customize thread specifications?

A: Yes, we manufacture nuts according to your exact thread requirements and dimensional specifications.

Q: How does the nylon lock insert work?

A: The nylon insert creates friction against the mating thread, preventing loosening from vibration or thermal cycling.

Q: What's the maximum operating temperature?

A: Our titanium nuts can operate safely from -200°C to +400°C depending on the specific application.

Q: Do you provide material certificates?

A: Yes, complete material certification and test reports accompany every order.

Why Choose Us

Baoji Chuanglian brings over ten years of titanium expertise to your projects. We're located in Baoji City, known as the "City of Titanium," giving us access to the finest raw materials and specialized knowledge.

Our complete quality control system ensures consistent performance. From raw material selection to final inspection, we maintain the highest standards. You benefit from our experience serving aerospace, medical, and marine industries worldwide.

We offer competitive pricing without compromising quality. Our efficient manufacturing processes and direct material sourcing provide excellent value. Long-term partnerships with global customers demonstrate our reliability and commitment to service excellence.

Contact Us

Ready to experience the superior performance of our Gr5 Titanium Nylock 12 Point Flange Nut? Our technical team is ready to discuss your specific requirements and provide detailed quotations.

Email: info@cltifastener.com

Get in touch today for custom solutions, technical specifications, or to place your order. We're committed to delivering the highest quality titanium fasteners for your most demanding applications.

Learn about our latest products and discounts through SMS or email