- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Titanium 12 Point Flange Nuts

Material: Pure titanium,Titanium alloy

Grade:Gr2,Gr5(Ti6al4v)

Processing:CNC machined

Surface Treatment: Polishing,Anodizing, Nitriding

Color:Ti nature,Gold,Blue,Green,Purple,Black,Rainbow

Advantage:light, acid and alkali resistance, anti-corrosion, excellent mechanical strength etc.

Titanium 12 Point Flange Nuts – High-Performance Fastening Solutions

Product Introduction

Titanium 12 Point Flange Nuts are precision-engineered fasteners designed for high-stress applications where strength, corrosion resistance, and lightweight properties are essential. Made from premium-grade titanium, these nuts provide superior durability, excellent temperature resistance, and a secure grip. Ideal for aerospace, automotive, marine, and industrial applications, they offer enhanced torque capability compared to standard hex nuts.

Technical Specifications

| Specification | Details |

|---|---|

| Material | Titanium Grade 2 / Grade 5 (Ti-6Al-4V) |

| Standard | DIN, ISO, JIS, ANSI |

| Sizes Available | M3 – M30, Custom Sizes Available |

| Surface Finish | Polished, Anodized, Plain, Customized Coating |

| Hardness | Rockwell C30-40 (for Grade 5) |

| Temperature Resistance | Up to 600°C |

| Corrosion Resistance | Excellent (Suitable for marine and chemical environments) |

Product Features

-

High Strength & Lightweight – Titanium provides exceptional strength while being 40% lighter than steel.

-

Superior Corrosion Resistance – Withstands harsh environments, including saltwater, acids, and extreme temperatures.

-

12-Point Design for Enhanced Torque – Offers better load distribution and prevents rounding off.

-

Excellent Heat Resistance – Suitable for high-temperature applications in aerospace and racing industries.

-

Long Service Life – Titanium's durability ensures long-term performance and reliability.

Applications

-

Aerospace & Aviation – Used in aircraft structures, engine components, and landing gear.

-

Automotive & Racing – Ideal for performance vehicles, exhaust systems, and suspension components.

-

Marine Engineering – Perfect for shipbuilding and offshore applications due to its corrosion resistance.

-

Medical Devices – Safe for surgical instruments and implants due to its biocompatibility.

-

Industrial & Chemical Processing – Essential for high-stress environments, reactors, and piping systems.

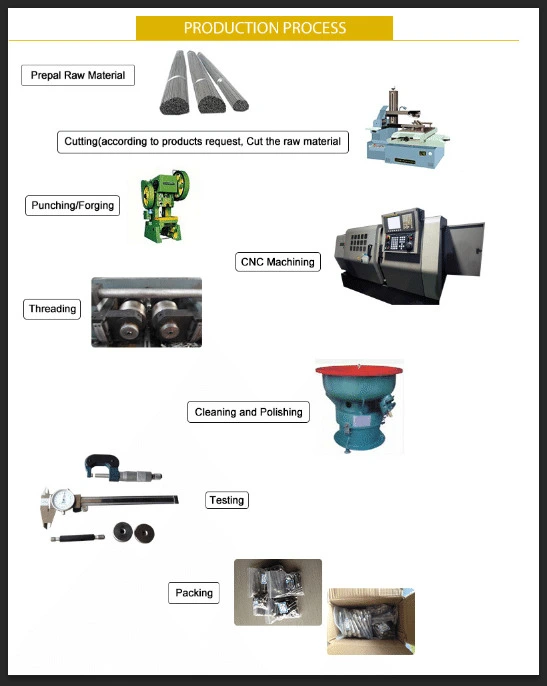

Manufacturing Process

Our Titanium 12 Point Flange Nuts are produced using a precision CNC machining process, ensuring tight tolerances and consistent quality. The steps include:

-

Raw Material Selection – High-quality titanium billets are sourced and inspected.

-

CNC Machining – Advanced machines shape the nuts with precision.

-

Threading & Finishing – Threads are cut to specification and surfaces treated for enhanced durability.

-

Quality Control – Each nut undergoes strict inspection to meet international standards.

Production workshop

Production process

Our Services

Custom solutions, fast delivery, competitive pricing, and excellent service.

Titanium Product Manufacturing

Baoji Chuanglian New Metal Material Co., Ltd specializes in manufacturing high-quality titanium and rare metal products. With over ten years of experience, we produce titanium rods, plates, tubes, fasteners, and customized components. Our products meet strict national and international standards, ensuring durability and reliability. We cater to industries such as aerospace, medical, and petrochemical, providing high-performance titanium solutions tailored to customer needs.

Precision Titanium Machining

Equipped with advanced CNC machines, we offer precision machining services, including cutting, milling, drilling, and turning. Our experienced technicians ensure high accuracy and quality in every component. By continuously upgrading our technology, we meet complex machining demands for various industries. Whether you need standard titanium parts or custom-designed solutions, we provide efficient and reliable services.

Strict Quality Control

We maintain a rigorous quality control system from raw material selection to final inspection. Every product undergoes thorough testing to ensure superior performance and longevity. Our titanium products have been trusted by global companies for years, earning a reputation for reliability. With strict adherence to quality standards, we guarantee high-quality products with on-time delivery.

Global Titanium Solutions

Serving industries worldwide, we provide professional titanium solutions, from production to after-sales support. Our products are widely used in aerospace, medical, marine, and industrial fields. We focus on customer satisfaction, offering customized services and technical assistance. With a commitment to innovation and quality, we strive to build long-term partnerships and deliver high-value titanium products globally.

Be used in a wide range of industries.

Automotive Industry

Electronics Industry

Aerospace Industry

Medical Industry

Cars and Racing

Consumer Electronics

Why Choose Us?

Decades of Expertise

With over 10 years of experience, we deliver precise, high-quality titanium products tailored to industry standards.

Customized Solutions

We provide customized titanium solutions to meet your specific needs, ensuring optimal performance and satisfaction.

Advanced Technology

Our cutting-edge machinery ensures precise manufacturing, offering innovative and reliable titanium solutions.

Global Support

We offer excellent customer service, fast delivery, and reliable after-sales support worldwide.

Quality Assurance

| Inspection Process | Description |

| Material Testing | Ensures compliance with ASTM and ISO standards |

| Dimensional Accuracy | CNC precision for perfect fit |

| Surface Treatment Inspection | Ensures corrosion resistance and smooth finish |

| Mechanical Strength Testing | Confirms high load-bearing capacity |

| Final Quality Check | 100% inspection before shipment |

Packaging and Logistics

-

Packaging: Securely packed in plastic bags, boxes, or customized packaging.

-

Shipping: Global delivery with fast lead times.

-

Custom Labeling: Available upon request.

Customer Support

Our team offers dedicated customer support, ensuring quick responses to inquiries and technical assistance for selecting the right titanium fasteners for your needs.

Why Choose Us?

-

Over 10 Years of Experience in titanium fastener manufacturing.

-

Advanced CNC Machinery for precision machining.

-

Strict Quality Control System to meet global standards.

-

Competitive Pricing without compromising quality.

-

Fast & Reliable Delivery worldwide.

OEM Services

We provide custom OEM services, including:

-

Custom sizes and specifications

-

Special coatings and surface treatments

-

Private labeling and branding

Frequently Asked Questions (FAQs)

Q: Are your Titanium 12 Point Flange Nuts certified?

A: Yes, they comply with ASTM, ISO, and other international standards.

Q: Can you produce custom sizes?

A: Yes, we offer custom sizes and specifications based on your requirements.

Q: How long is the delivery time?

A: Standard sizes are available for quick shipping. Custom orders typically take 2-4 weeks.

Q: Do you offer samples?

A: Yes, we provide samples for quality evaluation.

Contact Us

For inquiries and orders, contact us today:

📧 Email: info@cltifastener.com

📞 Phone: +86 13571186580

Get in touch now to secure high-quality Titanium 12 Point Flange Nuts for your applications!

Learn about our latest products and discounts through SMS or email