- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

DIN914 Titanium Cone-Point Hex Socket Set Screw

Material: Pure titanium,Titanium alloy

Grade:Gr2,Gr5(Ti6al4v)

Processing:CNC machined

Surface Treatment: Polishing,Anodizing, Nitriding

Color:Ti nature,Gold,Blue,Green,Purple,Black,Rainbow

Advantage:light, acid and alkali resistance, anti-corrosion, excellent mechanical strength etc.

DIN914 Titanium Cone-Point Hex Socket Set Screw

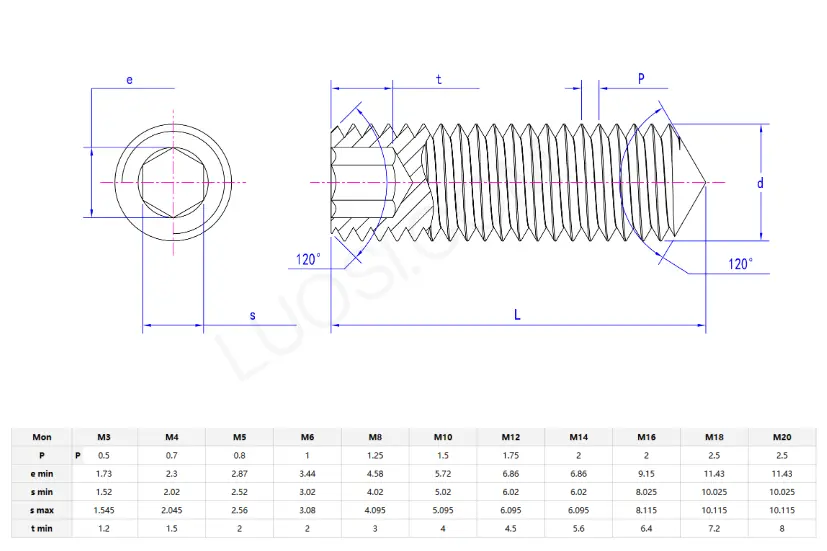

Product Parameters:DIN914

Product Introduction

Looking for premium fastening solutions that deliver exceptional strength and corrosion resistance? The DIN914 Titanium Cone-Point Hex Socket Set Screw offers the perfect combination of lightweight construction and superior performance. These precision-engineered fasteners are manufactured from high-grade titanium materials, making them ideal for demanding applications where traditional steel screws simply won't perform. Our cone-point design ensures reliable positioning and secure fastening in threaded holes. Each screw features a hexagonal socket head for easy installation with standard Allen keys. You can trust our titanium set screws to deliver long-lasting performance in the most challenging environments.

At Baoji Chuanglian New Metal Material Co., Ltd., we understand your need for reliable fastening solutions. Our manufacturing facility in China's "City of Titanium" gives us direct access to premium raw materials and advanced processing capabilities.

Technical Specifications

| Property | Specification |

|---|---|

| Standard | DIN914 / Customized |

| Material | Pure Titanium, Titanium Alloy |

| Grade | Gr2, Gr5 (Ti6Al4V) |

| Thread | M3-M20 (Custom sizes available) |

| Processing | CNC Machined |

| Surface Treatment | Polishing, Anodizing, Nitriding |

| Color Options | Natural, Gold, Blue, Green, Purple, Black, Rainbow |

| Point Type | Cone Point |

| Socket Type | Hexagonal |

| Tolerance | ±0.05mm |

Key Features

Lightweight Construction: Titanium offers 40% weight reduction compared to steel while maintaining superior strength.

Corrosion Resistance: Excellent performance in saltwater, acids, and alkaline environments.

High Strength-to-Weight Ratio: Perfect for aerospace and high-performance applications.

Precision Threading: CNC machined threads ensure perfect fit and easy installation.

Multiple Surface Finishes: Choose from natural titanium or colorful anodized options.

Temperature Stability: Maintains properties in extreme temperature conditions.

Product Characteristics

Your titanium cone-point set screws deliver exceptional mechanical properties that outperform traditional materials. The cone-point design provides precise positioning and prevents loosening under vibration. Our hexagonal socket design allows for high-torque installation while maintaining compact dimensions.

The biocompatible nature of titanium makes these fasteners suitable for medical applications. You'll appreciate the non-magnetic properties when working with sensitive electronic equipment. Each DIN914 Titanium Cone-Point Hex Socket Set Screw undergoes rigorous quality testing to ensure consistent performance.

Applications

Aerospace Industry: Aircraft components, satellite systems, spacecraft assemblies

Medical Equipment: Surgical instruments, prosthetics, diagnostic machinery

Marine Engineering: Boat hardware, offshore platforms, submarine components

Automotive Racing: High-performance engines, chassis components, suspension systems

Chemical Processing: Reactor vessels, piping systems, process equipment

Electronics: Precision instruments, testing equipment, manufacturing tools

Industrial Machinery: Positioning devices, alignment systems, custom fixtures

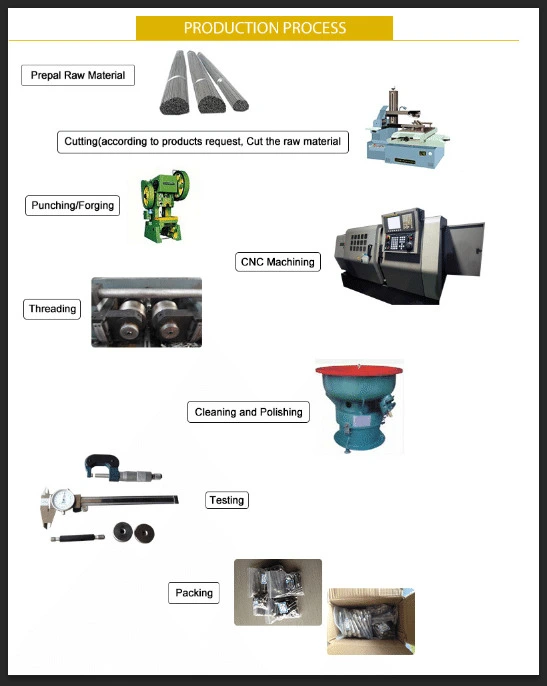

Manufacturing and Processing Capabilities

Our state-of-the-art facility houses complete CNC machining centers capable of producing complex geometries with tight tolerances. We maintain full traceability from raw material certification through final inspection. Our experienced technicians utilize advanced programming to ensure consistent quality across production runs.

Quality control begins with incoming material inspection and continues through each processing step. We can accommodate both standard DIN914 specifications and custom modifications to meet your unique requirements.

Production workshop

Production process

Our Services

Custom solutions, fast delivery, competitive pricing, and excellent service.

Titanium Product Manufacturing

Baoji Chuanglian New Metal Material Co., Ltd specializes in manufacturing high-quality titanium and rare metal products. With over ten years of experience, we produce titanium rods, plates, tubes, fasteners, and customized components. Our products meet strict national and international standards, ensuring durability and reliability. We cater to industries such as aerospace, medical, and petrochemical, providing high-performance titanium solutions tailored to customer needs.

Precision Titanium Machining

Equipped with advanced CNC machines, we offer precision machining services, including cutting, milling, drilling, and turning. Our experienced technicians ensure high accuracy and quality in every component. By continuously upgrading our technology, we meet complex machining demands for various industries. Whether you need standard titanium parts or custom-designed solutions, we provide efficient and reliable services.

Strict Quality Control

We maintain a rigorous quality control system from raw material selection to final inspection. Every product undergoes thorough testing to ensure superior performance and longevity. Our titanium products have been trusted by global companies for years, earning a reputation for reliability. With strict adherence to quality standards, we guarantee high-quality products with on-time delivery.

Global Titanium Solutions

Serving industries worldwide, we provide professional titanium solutions, from production to after-sales support. Our products are widely used in aerospace, medical, marine, and industrial fields. We focus on customer satisfaction, offering customized services and technical assistance. With a commitment to innovation and quality, we strive to build long-term partnerships and deliver high-value titanium products globally.

Be used in a wide range of industries.

Automotive Industry

Electronics Industry

Aerospace Industry

Medical Industry

Cars and Racing

Consumer Electronics

Why Choose Us?

Decades of Expertise

With over 10 years of experience, we deliver precise, high-quality titanium products tailored to industry standards.

Customized Solutions

We provide customized titanium solutions to meet your specific needs, ensuring optimal performance and satisfaction.

Advanced Technology

Our cutting-edge machinery ensures precise manufacturing, offering innovative and reliable titanium solutions.

Global Support

We offer excellent customer service, fast delivery, and reliable after-sales support worldwide.

Quality Assurance

Every batch undergoes comprehensive testing including dimensional verification, material composition analysis, and mechanical property testing. Our quality management system ensures consistent delivery of products that meet international standards.

We maintain detailed documentation for each production lot, providing full traceability when required. Regular calibration of measuring equipment and ongoing process validation guarantee reliable results.

Packaging and Logistics

Your orders receive careful packaging to prevent damage during shipping. We use anti-static materials and proper cushioning for sensitive applications. Standard packaging includes detailed labeling with part numbers, quantities, and material certifications.

We work with reliable logistics partners to ensure timely delivery worldwide. Express shipping options are available for urgent requirements. Bulk orders can be customized with special packaging solutions.

FAQ

Q: What's the minimum order quantity for custom sizes?

A: We can accommodate orders starting from 100 pieces for custom specifications.

Q: How long does production take?

A: Standard sizes ship within 7-10 days. Custom orders typically require 2-3 weeks.

Q: Can you provide material certificates?

A: Yes, we include mill certificates with each shipment showing chemical composition and mechanical properties.

Q: What torque values should I use for installation?

A: We recommend starting at 70% of standard steel torque values and adjusting based on your application requirements.

Why Choose Us

With over ten years of titanium processing experience, we bring proven expertise to every project. Our location in Baoji gives us access to the world's finest titanium raw materials. You benefit from our complete quality control system and advanced manufacturing capabilities.

We pride ourselves on building long-term partnerships through consistent quality and reliable service. Our technical team provides ongoing support to help you select the right DIN914 Titanium Cone-Point Hex Socket Set Screw for your application.

Contact Us

Ready to experience the performance advantages of premium titanium fasteners? Our technical sales team is here to help you select the perfect solution for your needs.

Email: info@cltifastener.com / djy6580@aliyun.com

Contact us today for detailed specifications, pricing information, or technical support. We look forward to supporting your next project with high-quality titanium fastening solutions.

Learn about our latest products and discounts through SMS or email

_1742980398281.webp)