- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Titanium Drilled Spacer Washer For Motorcycle Modification

Material: Titanium alloy

Grade:Gr5(Ti6al4v)

Processing:CNC machined

Surface Treatment: Polishing,Anodizing, Nitriding

Color:Ti nature,Gold,Blue,Green,Purple,Black,Rainbow

Advantage:light, acid and alkali resistance, anti-corrosion, excellent mechanical strength etc.

Titanium Drilled Spacer Washer For Motorcycle Modification

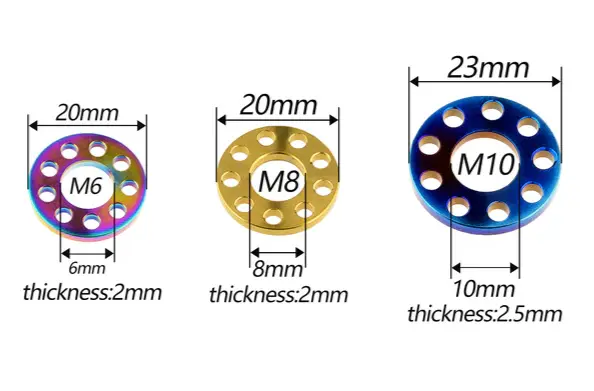

Product Parameters:

Product Introduction

Transform your motorcycle with our premium Titanium Drilled Spacer Washer For Motorcycle Modification. These precision-engineered components offer the perfect combination of strength, style, and weight reduction for serious bike enthusiasts. Made from high-grade pure titanium and titanium alloy, our spacer washers deliver exceptional performance while adding a distinctive look to your ride. Whether you're building a custom bike or upgrading your existing machine, these titanium washers provide the reliability and aesthetics you need.

Each washer undergoes CNC machining to ensure perfect fit and finish. The drilled design not only reduces weight but also adds visual appeal to your motorcycle's components. Built to withstand the demands of high-performance riding, these washers resist corrosion and maintain their appearance even in harsh conditions.

Technical Specifications

| Specification | Details |

|---|---|

| Standard | Customized |

| Material | Titanium Alloy |

| Grade | Gr5 (Ti6Al4V) |

| Processing | CNC Machined |

| Surface Treatment | Polishing, Anodizing, Nitriding |

| Available Colors | Natural Titanium, Gold, Blue, Green, Purple, Black, Rainbow |

| Size Range | M5-M12 or Customizable size |

| Hole Pattern | Single or Multiple Drilled Holes |

| Temperature Range | -253°C to +600°C |

Key Features

- Ultra-Lightweight Design: Titanium construction reduces weight by up to 40% compared to steel alternatives

- Exceptional Strength: Superior strength-to-weight ratio for demanding applications

- Corrosion Resistant: Outstanding resistance to salt, moisture, and chemicals

- Precision Machined: CNC manufacturing ensures consistent quality and perfect fitment

- Custom Colors: Multiple anodizing options to match your bike's aesthetic

- Heat Resistant: Maintains properties even under extreme temperature conditions

Product Characteristics

Our titanium spacer washers excel in motorcycle applications due to their unique material properties. The biocompatible nature of titanium makes these washers safe for all environments. They won't react with other metals, preventing galvanic corrosion that commonly affects steel components.

The drilled pattern serves multiple purposes beyond aesthetics. It provides additional weight savings while maintaining structural integrity. The holes can also help with heat dissipation and provide mounting points for additional accessories.

Each Titanium Drilled Spacer Washer For Motorcycle Modification features a smooth surface finish that resists dirt and grime buildup. This characteristic makes maintenance easier and keeps your bike looking pristine longer.

Applications

- Engine Bay Components: Spacing and alignment for various engine accessories

- Suspension Systems: Proper spacing in fork and shock assemblies

- Brake Systems: Caliper mounting and rotor spacing applications

- Custom Builds: Unique spacing solutions for one-off motorcycle projects

- Racing Applications: Weight reduction for competitive racing motorcycles

- Restoration Projects: High-quality replacements for vintage motorcycle restoration

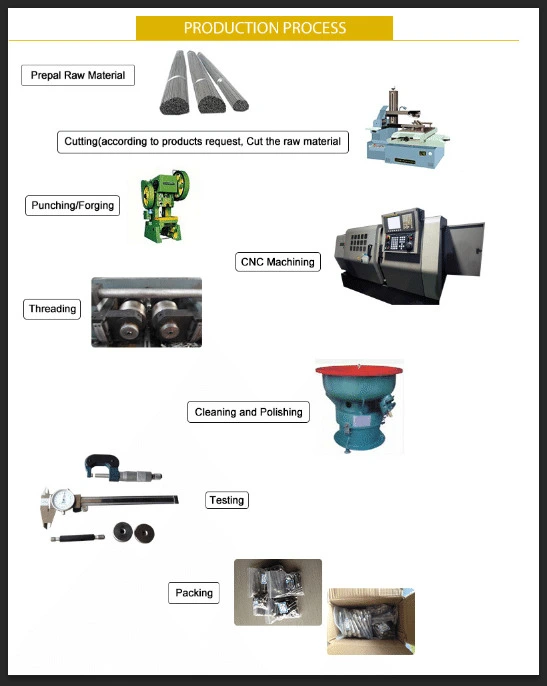

Manufacturing and Processing Capabilities

Baoji Chuanglian operates state-of-the-art CNC machining centers capable of producing washers to extremely tight tolerances. Our manufacturing process begins with premium-grade titanium raw materials that meet international standards.

Each washer undergoes multiple quality checkpoints during production. Our skilled technicians monitor every step to ensure consistent results. The drilling process uses specialized tooling designed specifically for titanium to prevent work hardening and maintain material properties.

We can accommodate orders from small custom batches to large production runs. Our flexible manufacturing setup allows for rapid prototyping and design modifications based on your specific requirements.

Production workshop

Production process

Our Services

Custom solutions, fast delivery, competitive pricing, and excellent service.

Titanium Product Manufacturing

Baoji Chuanglian New Metal Material Co., Ltd specializes in manufacturing high-quality titanium and rare metal products. With over ten years of experience, we produce titanium rods, plates, tubes, fasteners, and customized components. Our products meet strict national and international standards, ensuring durability and reliability. We cater to industries such as aerospace, medical, and petrochemical, providing high-performance titanium solutions tailored to customer needs.

Precision Titanium Machining

Equipped with advanced CNC machines, we offer precision machining services, including cutting, milling, drilling, and turning. Our experienced technicians ensure high accuracy and quality in every component. By continuously upgrading our technology, we meet complex machining demands for various industries. Whether you need standard titanium parts or custom-designed solutions, we provide efficient and reliable services.

Strict Quality Control

We maintain a rigorous quality control system from raw material selection to final inspection. Every product undergoes thorough testing to ensure superior performance and longevity. Our titanium products have been trusted by global companies for years, earning a reputation for reliability. With strict adherence to quality standards, we guarantee high-quality products with on-time delivery.

Global Titanium Solutions

Serving industries worldwide, we provide professional titanium solutions, from production to after-sales support. Our products are widely used in aerospace, medical, marine, and industrial fields. We focus on customer satisfaction, offering customized services and technical assistance. With a commitment to innovation and quality, we strive to build long-term partnerships and deliver high-value titanium products globally.

Be used in a wide range of industries.

Automotive Industry

Electronics Industry

Aerospace Industry

Medical Industry

Cars and Racing

Consumer Electronics

Why Choose Us?

Decades of Expertise

With over 10 years of experience, we deliver precise, high-quality titanium products tailored to industry standards.

Customized Solutions

We provide customized titanium solutions to meet your specific needs, ensuring optimal performance and satisfaction.

Advanced Technology

Our cutting-edge machinery ensures precise manufacturing, offering innovative and reliable titanium solutions.

Global Support

We offer excellent customer service, fast delivery, and reliable after-sales support worldwide.

Quality Assurance

Quality control remains at the heart of our manufacturing process. We inspect raw materials upon arrival and conduct in-process monitoring throughout production. Final inspection includes dimensional verification, surface quality assessment, and material certification.

Our quality management system ensures traceability from raw material to finished product. This comprehensive approach has earned us recognition from customers worldwide who depend on consistent, reliable components for their motorcycle projects.

Packaging and Logistics

We carefully package each Titanium Drilled Spacer Washer For Motorcycle Modification to prevent damage during shipping. Protective materials and proper cushioning ensure your washers arrive in perfect condition.

Standard packaging includes anti-static bags and protective foam inserts. For larger orders, we use custom packaging solutions tailored to your specific needs. Rush orders receive priority handling to meet your project deadlines.

FAQ

Q: Can you make custom sizes and hole patterns?

A: Yes, we specialize in custom manufacturing. Send us your specifications for a detailed quote.

Q: How long does anodizing last on motorcycle applications?

A: Our anodizing process creates a durable finish that typically lasts several years under normal riding conditions.

Q: Are these washers compatible with stainless steel bolts?

A: Absolutely. Titanium is compatible with stainless steel and won't cause galvanic corrosion.

Q: What's the minimum order quantity?

A: We can accommodate orders starting from single pieces for prototyping up to large production runs.

Why Choose Us

Baoji Chuanglian brings over ten years of titanium expertise to every project. Located in China's "City of Titanium," we have unparalleled access to premium raw materials and specialized knowledge.

Our commitment to continuous improvement drives us to invest in the latest equipment and training. This dedication ensures you receive the highest quality Titanium Drilled Spacer Washer For Motorcycle Modification available in the market.

We understand that motorcycle enthusiasts demand perfection. That's why we maintain strict quality standards and offer comprehensive support throughout your project. From initial consultation to final delivery, our team works to exceed your expectations.

Contact Us

Ready to upgrade your motorcycle with premium titanium components? Our experienced team stands ready to assist with your project requirements.

Email: info@cltifastener.com

Alternative Email: djy6580@aliyun.com

Contact us today for custom quotes, technical specifications, or to discuss your specific motorcycle modification needs. We look forward to helping you create something extraordinary.

Learn about our latest products and discounts through SMS or email