- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

titanium wire suppliers

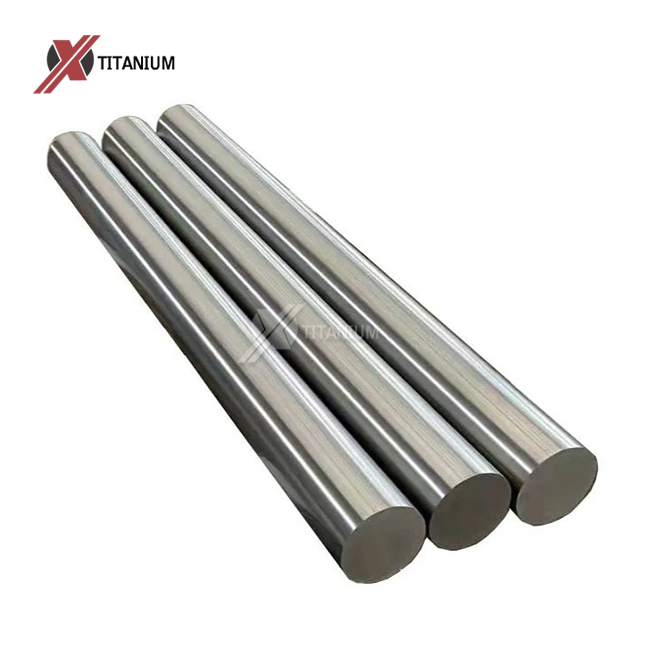

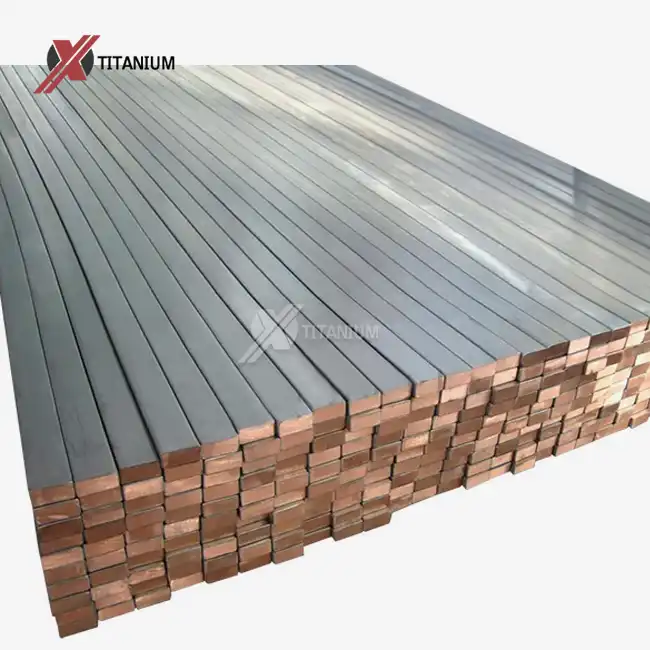

Surface:Bright, Polished, Pickling, Acid cleaning, Sandblasting

Quality and test:Hardness test, Bending test, Hydrostatic etc.

Feature:High corrosion resistance, low density, good thermal stability

Application:Chemical, industry, sports etc.

Titanium Wire Suppliers – High-Quality Titanium Wire for Various Industrial Applications

1. Product Introduction

Titanium wire is a lightweight, corrosion-resistant material widely used in aerospace, medical, chemical, and industrial applications. As a leading titanium wire supplier, Baoji Chuanglian New Metal Material Co., Ltd. offers high-purity titanium wire that meets international standards, ensuring durability, strength, and superior performance.

2. Technical Specifications

| Grade | Standard | Diameter Range | Surface Finish |

|---|---|---|---|

| Gr1, Gr2, Gr5 | ASTM B863, AMS 4928 | 0.1mm – 6.0mm | Polished, Pickled |

| Gr7, Gr9, Gr12 | ASTM B348, ISO 9001 | 0.2mm – 5.0mm | Black, Bright |

| Gr23 (Ti-6Al-4V ELI) | ASTM F136, ASTM F67 | 0.5mm – 4.0mm | Sandblasted |

| Tensile Strength | Yield Strength | Elongation |

| 275-950 MPa | 170-880 MPa | ≥20% |

| Density | Melting Point | Hardness (HV) |

| 4.51 g/cm³ | 1668°C | 160-340 |

3. Product Features (Key Features)

-

Lightweight & High Strength – Ideal for high-performance applications.

-

Corrosion Resistance – Withstands harsh environments, including seawater and chemicals.

-

Biocompatibility – Safe for medical implants and surgical instruments.

-

Excellent Weldability & Machinability – Suitable for various industrial processes.

-

High-Temperature Resistance – Performs well under extreme conditions.

4. Applications

-

Aerospace & Aviation – Used in aircraft components and spacecraft.

-

Medical & Healthcare – Surgical tools, orthopedic implants, and dental braces.

-

Chemical Processing – Heat exchangers, reactors, and filtration systems.

-

Marine Engineering – Corrosion-resistant parts for ships and offshore structures.

-

Industrial Manufacturing – Fasteners, springs, and electronic components.

5. Manufacturing Process

-

Raw Material Selection – Premium titanium sponge is used.

-

Melting & Casting – Vacuum arc remelting ensures purity.

-

Forming & Drawing – Titanium wire is shaped into the desired diameter.

-

Heat Treatment – Enhances mechanical properties.

-

Surface Finishing – Pickling, polishing, or sandblasting for optimal quality.

-

Quality Control – Stringent inspections ensure compliance with global standards.

6. Quality Assurance

-

ISO 9001 & ASTM Certified – Ensuring international quality compliance.

-

Strict Inspection – Dimensional, mechanical, and chemical analysis.

-

Non-Destructive Testing (NDT) – Ultrasonic, eddy current, and X-ray testing.

-

Material Traceability – Full documentation for each batch.

7. Packaging and Logistics

-

Packaging: Vacuum-sealed, plastic spool, wooden case, or customized packaging.

-

Shipping: Worldwide delivery with fast and reliable logistics partners.

-

Custom Labeling: Available upon request.

8. Customer Support

-

Expert Consultation: Our engineers provide material selection and technical support.

-

Fast Response: Inquiries are handled within 24 hours.

9. Why Choose Us?

-

Over 10 Years of Experience in titanium and rare metal manufacturing.

-

Advanced Equipment for precision machining and processing.

-

Competitive Pricing with consistent supply capability.

-

Custom Solutions to meet specific project requirements.

-

Global Distribution with a strong network in North America, Europe, and Asia.

10. OEM Services

-

Custom Titanium Wire Production – Tailored diameters, lengths, and finishes.

-

Private Labeling & Branding – OEM services available.

-

Flexible Order Quantities – Small and bulk orders accommodated.

11. Frequently Asked Questions (FAQs)

Q1: What is the minimum order quantity (MOQ)?

A: Our MOQ varies based on specifications, but we support small trial orders.

Q2: Can you provide material certifications?

A: Yes, we provide ISO, ASTM, and mill test reports (MTRs).

Q3: How long is the lead time?

A: Standard sizes ship within 7-15 days, custom orders take 20-30 days.

Q4: Do you offer samples?

A: Yes, free samples are available; shipping costs are covered by the buyer.

Q5: How do I place an order?

A: Contact us via email at info@cltifastener.com or call +8613571186580.

12. Contact Details

For more information on our high-quality titanium wire suppliers, reach out to us:

-

Email: info@cltifastener.com

-

Phone: +8613571186580

-

Location: Baoji Chuanglian New Metal Material Co., Ltd., Baoji City, China

Partner with a trusted titanium wire supplier today and ensure high-quality materials for your industry needs!

Learn about our latest products and discounts through SMS or email