When it comes to high-temperature industrial applications, titanium flange bolts stand out as the ultimate solution for demanding environments where conventional fasteners simply cannot perform. These specialized components combine exceptional heat resistance with superior corrosion protection, making them indispensable for aerospace engines, petrochemical processing equipment, and marine offshore platforms. The unique metallurgical properties of titanium alloys enable these fasteners to maintain structural integrity at temperatures exceeding 600°C while resisting aggressive chemical environments. Industries requiring reliable performance under extreme conditions consistently choose titanium-based solutions over traditional steel alternatives. The lightweight nature of these advanced materials reduces overall system weight without compromising mechanical strength, delivering optimal performance across diverse applications.

Why Focus on Titanium Flange Bolts for Extreme Environments?

The developing request for high-performance clamps in basic applications has positioned titanium rib jolts as basic components in numerous businesses. Aviation producers confront progressively rigid weight lessening requirements whereas keeping up security benchmarks, driving the appropriation of lightweight materials with uncommon malleable quality. Petrochemical offices work in destructive situations where standard latches come up short rashly, coming about in exorbitant support and security concerns.

Marine building ventures experience saltwater presentation that quickly debases ordinary equipment, making erosion resistance a essential concern. Therapeutic gadget producers require biocompatible materials that won't trigger antagonistic responses in human tissue. The semiconductor industry requests exactness building arrangements that can withstand high-temperature preparing without contamination. These challenging prerequisites have made titanium amalgam components the favored choice for engineers looking for solid, long-term arrangements. The prevalent chemical resistance and warm resistance properties of titanium-based clasp altogether diminish upkeep costs whereas improving operational safety.

Selection Criteria for Superior Titanium Fasteners

Evaluating titanium flange bolts requires understanding different performance variables that directly affect application success, including load capacity, fatigue resistance, corrosion behavior, dimensional accuracy, and compliance with specific industry standards. Fabric review determination shapes the establishment of appropriate latch determination, with Review 2 titanium advertising great erosion resistance for common applications, whereas Review 5 (Ti-6Al-4V) gives upgraded mechanical properties for high-stress environments.

Temperature resistance capabilities must adjust with operational necessities, considering both nonstop working temperatures and top warm introduction. Erosion resistance assessment includes testing against particular chemical situations, counting acids, soluble bases, and saltwater conditions. Mechanical properties evaluation envelops pliable quality, abdicate quality, and weakness resistance beneath cyclic loading. Manufacturing quality pointers incorporate dimensional precision, surface wrap up determinations, and threading accuracy.

Certification compliance with industry measures such as ASTM B348, AMS determinations, and ISO prerequisites guarantees dependable execution. Provider capabilities counting AS9100 aviation certification, ISO9001 quality administration, and therapeutic gadget compliance illustrate fabricating capability. Cost-effectiveness investigation considers beginning venture against lifecycle execution, counting decreased upkeep necessities and amplified benefit life. Supply chain unwavering quality envelops conveyance consistency, specialized back accessibility, and long-term provider stability.

Top 6 Titanium Flange Bolts for High-Temperature Performance

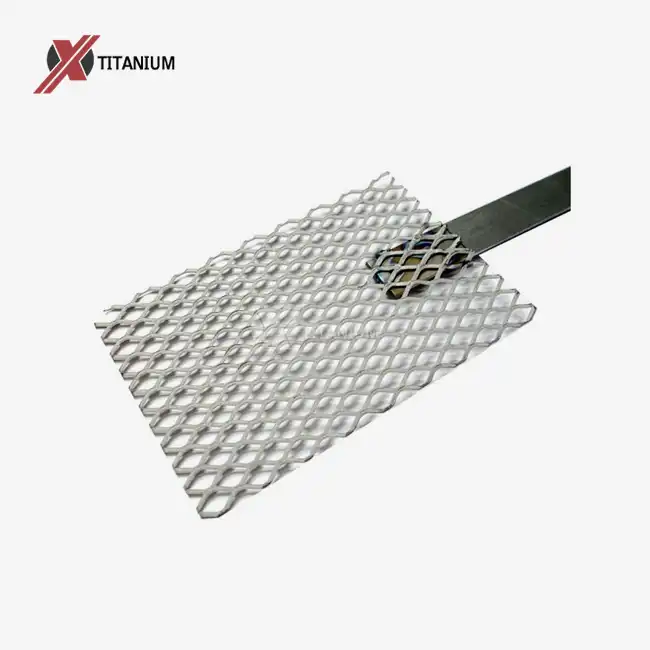

Grade 5 Titanium Hex Flange Bolts (Ti-6Al-4V)

Grade 5 titanium hex rib jolts speak to the gold standard for high-strength aviation applications requiring extraordinary mechanical properties. These precision-engineered clasp include the Ti-6Al-4V combination composition, conveying malleable quality surpassing 900 MPa whereas keeping up fabulous ductility. The coordinates rib plan kills the require for isolated washers, lessening component number and moving forward establishment efficiency. Key preferences incorporate predominant weakness resistance beneath cyclic stacking conditions, making them perfect for flying machine motor mounts and turning apparatus applications.

The hex head arrangement gives secure instrument engagement, anticipating slippage amid establishment or expulsion. Surface medications counting anodizing and nitriding improve wear resistance whereas giving unmistakable color coding for simple identification. Applications span aviation basic gatherings, high-performance car components, and mechanical gear working in extraordinary situations. The lightweight nature decreases generally framework weight by up to 45% compared to steel reciprocals, contributing to fuel proficiency changes in transportation applications.

Erosion resistance testing illustrates amazing execution in saltwater situations, amplifying benefit life in marine applications. Manufacturing details incorporate breadth ranges from M6 to M24, with custom sizes accessible for specialized applications. String pitch acclimates to ISO metric guidelines, guaranteeing compatibility with existing equipment. Quality certifications incorporate aviation AS9100 compliance and full fabric traceability documentation. Temperature execution remains steady up to 400°C persistent operation, with short-term introduction capability to 550°C. Chemical resistance envelops most mechanical acids, soluble bases, and natural solvents, making these clasp appropriate for chemical handling equipment.

Grade 2 Titanium Socket Head Flange Bolts

Grade 2 titanium attachment head rib jolts offer ideal erosion resistance for marine and chemical preparing applications where forceful situations challenge customary latches. The commercially immaculate titanium composition gives great chemical dormancy whereas keeping up satisfactory mechanical quality for moderate-stress applications. The attachment head plan empowers establishment in restricted spaces where customary hex heads cannot oblige standard instruments. The coordinates spine conveys clamping loads over bigger bearing zones, lessening contact stretch on mating surfaces. This plan highlight demonstrates especially important in composite fabric congregations where concentrated loads seem cause damage.

Manufacturing forms incorporate accuracy CNC machining from certified titanium bar stock, guaranteeing dimensional exactness and surface quality. Warm treatment conventions optimize mechanical properties whereas keeping up fabulous erosion resistance. Surface wraps up run from characteristic titanium appearance to enhancing anodized coatings in numerous colors. Marine applications advantage from remarkable saltwater resistance, with testing illustrating no quantifiable erosion after 1000 hours of salt shower introduction. Chemical handling gear utilizes these clasp for pump lodgings, valve congregations, and warm exchanger associations where stainless steel demonstrates inadequate.

Biomedical applications use the biocompatible properties of Review 2 titanium for surgical disobedient and implantable gadgets. The nonappearance of nickel and other possibly destructive components dispenses with unfavorably susceptible responses in delicate patients. Sterilization compatibility incorporates steam autoclaving, gamma radiation, and ethylene oxide processes. Standard sizes run from M4 to M20, with custom measurements accessible for specialized necessities. String details incorporate both metric and royal alternatives, pleasing different universal guidelines. Quality documentation incorporates fabric certificates, dimensional review reports, and traceability records.

Ti-6Al-4V Flanged Button Head Bolts

Ti-6Al-4V flanged button head jolts combine tasteful request with high-performance characteristics, making them perfect for applications where visual appearance things nearby useful prerequisites. The low-profile button head plan minimizes projection whereas giving satisfactory device engagement for secure installation. Advanced fabricating strategies guarantee steady head geometry and spine measurements, basic for applications requiring exact fit and wrap up. The smooth, adjusted head profile decreases catching dangers in gear where staff security is foremost. Surface medications counting cleaning and anodizing improve both appearance and execution characteristics.

Aerospace insides applications utilize these clasp for cabin boards, situate congregations, and gear mounting where traveler security requires secure connection without sharp edges. The titanium composition meets rigid combustibility prerequisites whereas giving great strength-to-weight ratios. High-end buyer gadgets applications advantage from the premium appearance and amazing erosion resistance of titanium clasp. Smartphone lodgings, tablet gatherings, and wearable gadgets utilize these components for both utilitarian and tasteful purposes. The normal color of titanium gives an alluring wrap up that complements cutting edge plan themes.

Racing applications use the lightweight properties and tall quality for basic chassis associations and suspension components. The diminished unsprung weight contributes to progressed taking care of characteristics whereas keeping up security edges. Vibration resistance guarantees secure associations beneath extraordinary working conditions. Quality details incorporate strict dimensional resistances and surface wrap up prerequisites. Head roundness, spine levelness, and string precision experience comprehensive assessment utilizing progressed metrology gear. Fabric properties confirmation incorporates pliable testing, hardness estimation, and chemical composition analysis.

Titanium Flange Bolts with Anti-Corrosion Coatings

Titanium rib jolts improved with specialized anti-corrosion coatings speak to the extreme arrangement for extraordinary chemical situations where indeed standard titanium requires extra assurance. These progressed latches combine the inalienable erosion resistance of titanium with built surface medicines planned for particular applications. Coating alternatives incorporate titanium nitride (TiN) for improved hardness and wear resistance, especially profitable in high-friction applications. Physical vapor statement (PVD) forms make thick, disciple coatings that stand up to chemical assault and mechanical wear.

Anodizing medications create controlled oxide layers that improve erosion resistance whereas giving unmistakable colors for recognizable proof purposes. Chemical preparing applications utilize these clasp in reactor vessels, refining columns, and channeling frameworks dealing with forceful media. The upgraded security expands benefit life in situations where uncoated titanium might encounter localized erosion. Testing conventions incorporate introduction to concentrated acids, high-temperature oxidizing conditions, and cyclic temperature variations. Offshore oil and gas stages speak to challenging situations where saltwater, hydrogen sulfide, and tall weights combine to make amazingly destructive conditions.

These improved latches keep up astuteness in subsea applications where substitution costs are restrictive. Long-term testing illustrates predominant execution compared to customary materials. Semiconductor fabricating gear requires clasp that won't sully ultra-pure preparing situations. Specialized coatings anticipate molecule era whereas keeping up chemical idleness. Cleanroom compatibility incorporates moo outgassing characteristics and resistance to forceful cleaning chemicals. Manufacturing forms include exact coating thickness control and grip testing to guarantee long-term execution. Quality confirmation incorporates coating consistency confirmation, attachment quality estimation, and quickened erosion testing. Certification documentation gives total traceability and execution validation.

Custom-Engineered Titanium Flange Fasteners

Custom-engineered titanium spine clasp address special application necessities that standard items cannot fulfill, giving custom-made arrangements for specialized businesses. These precision-manufactured components join particular dimensional necessities, fabric properties, and execution characteristics planned for person applications. Design adaptability envelops adjusted head geometries, specialized string shapes, and coordinates highlights such as captive washers or locking instruments. Progressed computer modeling and limited component examination optimize stretch dissemination and weariness life for basic applications.

Model advancement and testing approve execution some time recently full generation commitment. Aerospace investigate ventures regularly require latches with special determinations for test flying machine or shuttle applications. Custom combination compositions may join extra alloying components to upgrade particular properties such as high-temperature quality or radiation resistance. Broad testing conventions guarantee compliance with exacting aviation requirements.

Medical gadget applications as often as possible request custom arrangements for surgical disobedient or implantable gadgets. Biocompatibility testing incorporates cytotoxicity assessment, sensitization thinks about, and long-term implantation testing. Administrative compliance encompasses FDA prerequisites and worldwide regulatory device standards. Research and advancement applications utilize custom latches for model testing and specialized hardware.

Low-volume generation capabilities empower cost-effective arrangements for limited-quantity necessities. Specialized collaboration between engineers and clients guarantees ideal plan solutions. Manufacturing capabilities incorporate multi-axis CNC machining, exactness turning, and specialized warm treatment forms. Quality frameworks include total dimensional review, fabric confirmation, and execution testing. Documentation bundles incorporate point-by-point drawings, fabric certificates, and test reports.

High-Temperature Titanium Flange Bolts for Industrial Applications

High-temperature titanium flange bolts specifically engineered for industrial furnaces, power generation equipment, and chemical processing represent the pinnacle of thermal performance in fastener technology. These specialized components maintain mechanical properties and dimensional stability at elevated temperatures where conventional materials fail. Metallurgical engineering optimizes alloy composition and heat treatment for maximum high-temperature performance. Beta-annealed microstructures provide optimal creep resistance for long-term exposure to elevated temperatures.

Thermal expansion coefficients match common industrial materials, preventing thermal stress concentrations. Power generation applications include gas turbine assemblies, steam generator connections, and exhaust system components operating at extreme temperatures. The oxidation resistance of titanium prevents scale formation that could compromise joint integrity. Thermal cycling resistance ensures reliable performance under repeated heating and cooling cycles.

hemical processing equipment utilizes these fasteners for reactor vessel connections, catalyst bed supports, and high-temperature piping systems. The combination of temperature resistance and chemical inertness provides long-term reliability in demanding environments. Stress corrosion cracking resistance ensures safe operation under combined thermal and chemical stress. Furnace and kiln applications benefit from the dimensional stability and oxidation resistance of titanium fasteners.

Refractory material connections require fasteners that won't degrade at processing temperatures. The low thermal conductivity of titanium reduces heat transfer through fastener assemblies. Testing protocols include high-temperature tensile testing, creep testing, and oxidation resistance evaluation. Quality specifications encompass grain size control, surface condition requirements, and mechanical property verification. Certification includes material test reports and performance validation documentation.

Global Market Characteristics and Regulatory Considerations

The global market for titanium flange bolts reflects diverse regional requirements, regulatory frameworks, and cultural preferences that influence product specifications and procurement practices. North American markets emphasize aerospace and defense applications, driving demand for high-strength alloys with stringent certification requirements. European markets focus on chemical processing and marine applications, prioritizing corrosion resistance and environmental compliance. Asian markets, particularly in China and Japan, demonstrate strong growth in electronics and automotive applications, requiring precision engineering and cost-effective solutions.

The semiconductor industry in Taiwan and South Korea demands ultra-high-purity materials with minimal contamination risk. Indian and Southeast Asian markets show increasing adoption in infrastructure and energy projects. Regulatory compliance varies significantly across regions, with REACH regulations in Europe restricting certain surface treatments and requiring extensive documentation. FDA requirements in medical applications mandate biocompatibility testing and quality system compliance.

Military specifications in defense applications require specialized testing and certification protocols. Cultural preferences influence procurement decisions, with Western markets emphasizing individual supplier relationships and technical support, while Asian markets often prefer integrated supply chain solutions and competitive pricing. Long-term partnership approaches align with Japanese business practices, while project-based procurement characterizes many developing markets.

Purchasing Recommendations and Key Considerations

Successful procurement of titanium flange bolts requires careful evaluation of multiple factors beyond initial cost considerations. Material grade selection should align with specific application requirements, considering temperature exposure, chemical environment, and mechanical loading conditions. Grade 2 titanium provides excellent corrosion resistance for moderate-stress applications, while Grade 5 offers superior strength for demanding structural applications. Supplier qualification represents a critical success factor, encompassing technical capability, quality systems, and long-term stability.

Aerospace applications require AS9100 certification and full traceability documentation. Medical applications demand ISO13485 compliance and biocompatibility validation. Chemical processing applications benefit from NACE compliance and specialized testing capabilities. Quality documentation should include material certificates, dimensional inspection reports, and mechanical property verification. Traceability requirements may necessitate heat lot tracking and process documentation.

Testing protocols should encompass relevant performance characteristics for specific applications. Lead time planning accounts for material procurement, manufacturing processes, and quality verification activities. Custom specifications may require extended lead times for tooling development and prototype validation. Supply chain diversity reduces risk from single-source dependencies. Technical support capabilities enhance successful implementation, particularly for new applications or challenging environments. Engineering consultation services help optimize fastener selection and installation procedures. Post-delivery support ensures long-term performance and customer satisfaction.

Industry Trends and Market Outlook

The titanium fastener industry continues evolving toward advanced manufacturing techniques and specialized alloy development. Additive manufacturing technologies enable complex geometries and integrated features previously impossible with conventional machining. Advanced surface treatments enhance performance characteristics while reducing environmental impact. Digital quality systems provide real-time monitoring and predictive maintenance capabilities. Sustainable manufacturing practices address environmental concerns while maintaining performance standards. Market growth reflects expanding applications in renewable energy, electric vehicles, and next-generation aerospace systems, driving continued innovation in titanium fastener technology.

Conclusion

Selecting the best titanium flange bolts for high-temperature applications requires understanding material properties, application requirements, and supplier capabilities. The superior combination of lightweight design, exceptional corrosion resistance, and high-temperature performance makes titanium fasteners the optimal choice for demanding environments across aerospace, chemical processing, and marine industries. Proper material grade selection, quality certification verification, and supplier partnership development ensure long-term success in critical applications. Investment in premium titanium fastener solutions delivers significant lifecycle value through reduced maintenance, enhanced reliability, and improved operational safety.

Frequently Asked Questions

What temperature range can titanium flange bolts withstand in continuous operation?

Grade 2 titanium flange bolts can operate continuously at temperatures up to 315°C, while Grade 5 (Ti-6Al-4V) fasteners maintain mechanical properties up to 400°C continuous operation. Short-term exposure capabilities extend to 550°C for Grade 5 alloys, making them suitable for most high-temperature industrial applications, including aerospace engines and chemical processing equipment.

How do titanium flange bolts compare to stainless steel in corrosive environments?

Titanium flange bolts demonstrate superior corrosion resistance compared to stainless steel in most aggressive environments, particularly chloride-containing solutions, acids, and high-temperature oxidizing conditions. While 316 stainless steel may experience pitting corrosion in saltwater, titanium remains completely immune. The passive oxide layer on titanium provides exceptional protection even when mechanically damaged.

What certifications should I look for when purchasing titanium fasteners for aerospace applications?

Aerospace applications require AS9100 quality management certification, NADCAP approval for specialized processes, and compliance with relevant AMS (Aerospace Material Specifications) standards. Material certificates should include chemical composition verification, mechanical property testing, and complete heat lot traceability. Additional certifications may include DFARS compliance for defense applications and specific customer approval requirements.

Contact Chuanglian for Premium Titanium Flange Bolts

Chuanglian New Metal Material Co., Ltd. stands as your trusted titanium flange bolts manufacturer, delivering exceptional quality and reliability for demanding applications worldwide. Our state-of-the-art facility in Baoji, China's renowned "City of Titanium," combines over a decade of specialized experience with advanced CNC machining capabilities and rigorous quality control systems.

Our comprehensive titanium fastener solutions encompass Grade 2 and Grade 5 materials, custom surface treatments, and specialized engineering support tailored to your specific requirements. AS9100 aerospace certification, ISO9001 quality management, and medical device compliance demonstrate our commitment to excellence across diverse industries.

Whether you need standard hex flange bolts, custom-engineered solutions, or technical consultation for challenging applications, our experienced engineering team provides comprehensive support throughout your project lifecycle. Complete material traceability, dimensional accuracy, and performance validation ensure reliable operation in your critical applications. Ready to enhance your next project with superior titanium fastener solutions? Contact us at info@cltifastener.com or djy6580@aliyun.com to discuss your requirements and discover how our expertise can optimize your application performance.

References

1. Boyer, R.R."Titanium for Aerospace: Rationale and Applications." Advanced Performance Materials, Vol. 2, No. 4, 1995, pp. 349-368.

2. Schutz, R.W. and Watkins, H...B. "Recent Developments in Titanium Alloy Application in the Energy Industry." Materials Science and Engineering A, Vol. 243, No. 1-2, 1998, pp. 305-315.

3. American Society for Testing and Materials. "Standard Specification for Titanium and Titanium Alloy Bars and Billets." ASTM B348-19, ASTM International, 2019.

4. Donachie, Matthew J. "Titanium: A Technical Guide, 2nd Edition." ASM International, Materials Park, Ohio, 2000, pp. 215-243.

5. Veiga, C., Davim, J.P., andLourei AA.J.RJ. "Properties and Applications of Titanium Alloys: A Brief Review." Reviews on Advanced Materials Science, Vol. 32, No. 2, 2012, pp. 133-148.

6. Lutjering, G. and Williams, J.C".Titanium: Engineering Materials and Processes." Springer-Verlag, Berlin Heidelberg, 2nd Edition, 2007, pp. 442-467.