When engineers and procurement managers need to choose the best titanium screws for use in the maritime industry, they always choose titanium micro screws because they are the most resistant to corrosion and work well in tough saltwater conditions. These unique fasteners are the best maritime hardware technology has to offer. They last longer than regular stainless steel ones. Marine-grade titanium fasteners have proved themselves on offshore platforms, in shipbuilding projects, and in underwater instruments where failure is not an option. This in-depth article looks at the most important things that make titanium micro screws the best option for tough maritime applications.

Comprehending Titanium Micro Screws for Marine Use

Titanium micro screws are a breakthrough new kind of marine fastening technology that was designed to be strong enough to hold up in saltwater settings without corroding. These fasteners are made with high-quality titanium alloys that provide them performance features that can't be matched by regular materials.

What Are Titanium Micro Screws?

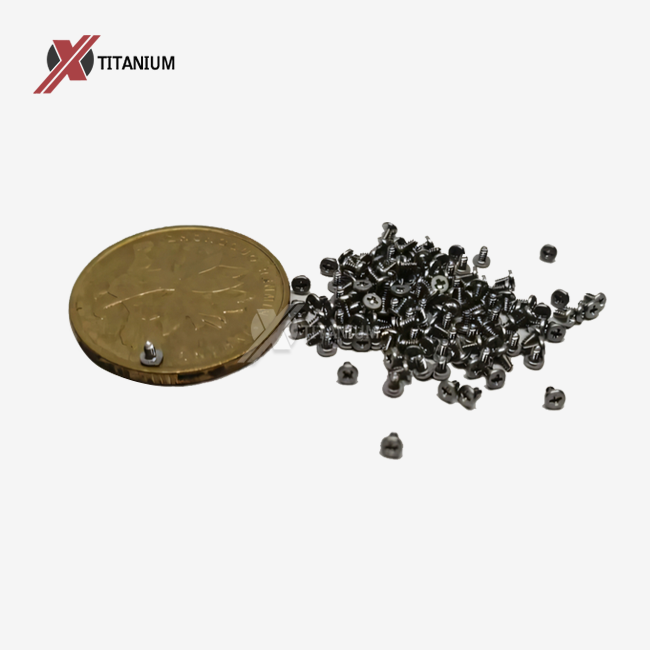

Titanium micro screws are made from pure titanium or a titanium alloy, such Grade 5 (Ti6Al4V), which gives them the best strength-to-weight ratios. Most of the time, these fasteners are between M1 and M3 in diameter, however they may be made to fit special nautical needs. The CNC machining technique makes sure that the threads and dimensions are just right, which is very important for putting together nautical equipment.

Surface treatments greatly improve their ability to perform. Polishing makes surfaces smooth, anodizing makes them less likely to rust, and nitriding makes them less likely to wear out. There are more color possibilities than just natural titanium. There are also gold, blue, green, purple, black, and rainbow finishes. This lets you think about both how the product looks and how it works in maritime applications.

Why Titanium Micro Screws are Ideal for Marine Applications?

Titanium micro screws can handle the special problems that come up in the maritime environment because of the way they are made. Saltwater, temperature changes, and mechanical stress all work together to quickly break down low-quality fastening materials. When titanium comes into contact with oxygen, it rapidly creates a natural oxide coating that protects it from further corrosion, even in harsh saltwater circumstances.

Another important benefit for maritime uses is that it makes things lighter. Titanium's density of 4.5 g/cm³ is lower than stainless steel's 8.0 g/cm³, which makes the vessel lighter and increases its fuel economy and cargo capacity. This weight reduction is especially important in aircraft marine applications and high-performance boats where every gram counts.

Technical Specifications Critical for Marine Use

Marine-grade titanium micro screws must fulfill strict technical standards to work reliably. ASTM B348 and ISO 5832 provide the standards for materials used in maritime applications. They spell out the chemical makeup, mechanical qualities, and testing methods that must be used. Grade 5 titanium alloy has a tensile strength of more than 900 MPa and is quite ductile.

When using threads in maritime settings, you need to pay close attention to the specs. Fine threads are better for holding thin materials together, which is frequent in maritime electronics. Coarse threads are better for keeping things from vibrating free in structural applications. Most surface finish standards ask for Ra values below 0.8 micrometers to reduce the number of places where crevice corrosion may start.

Titanium Micro Screws vs. Other Metals in Marine Environments

When choosing materials for maritime use, it's important to think about how resistant they are to corrosion, how strong they are, and how well they will hold up over time when exposed to seawater. Comparative investigation demonstrates substantial performance disparities between titanium and other materials often used in maritime fasteners.

Titanium vs Stainless Steel Micro Screws

Many people use stainless steel fasteners, however they don't work well in maritime settings. Titanium micro screws do. Type 316 stainless steel, which is marine-grade, has 16–18% chromium and 10–14% nickel. This makes it resistant to corrosion under moderate marine conditions. But in seawater, chloride ions may cause pitting corrosion and stress corrosion cracking over time.

The fact that titanium can generate a stable coating of titanium dioxide that repairs itself when injured is what makes it resistant to corrosion. This passive layer is stable at pH levels between 2 to 12, which is all marine environments. Laboratory tests show that titanium corroded in saltwater at a rate of less than 0.025 mm/year, whereas 316 stainless steel corroded at a rate of 0.127 mm/year under the same circumstances.

Titanium vs Cobalt Chrome and Other Metal Alternatives

Cobalt chrome alloys are great at resisting corrosion, but they have a few problems when used in maritime settings. Their density is close to 8.5 g/cm³, which is almost twice as heavy as titanium. This means that the weight-saving advantages that are so important in marine design are not possible. Also, titanium micro screws are more cost-effective for most maritime uses since cobalt is hard to find and costs more to create.

Aluminum fasteners are lighter, but they aren't strong enough for important maritime uses. They don't work well with other marine metals, which produces corrosion cells that speed up failure. Titanium works well with aluminum, stainless steel, and composite materials that are often utilized in maritime building.

Lightweight Properties and Impact on Marine Equipment Performance

Reducing the weight of naval equipment using titanium micro screws affects its performance in several ways. Every kilogram of weight that is taken off of offshore drilling rigs means less stress on the structure and better stability. Titanium fasteners help racing yachts save weight, which makes them faster and easier to handle.

Because titanium alloys have a high strength-to-weight ratio, designers may make fasteners smaller without losing their ability to hold weight. This smaller size makes it possible to construct equipment that takes up less space and uses less material in maritime applications where space is typically limited.

Selecting the Best Titanium Micro Screws for Marine Applications

To strategically buy titanium micro screws, you need to carefully look at the technical parameters, the capabilities of the suppliers, and the long-term performance needs. Marine applications need fasteners that can hold their shape and strength over a long period of time while also satisfying certain size and load criteria.

Key Decision Criteria for Procurement Managers

When choosing titanium micro screws for maritime use, procurement managers need to think about a lot of different things. Choosing the right material grade is the most important part of performance. Grade 5 (Ti6Al4V) has the best strength properties for most maritime uses. Thread parameters must match the materials they will be used with and the load they will be carrying. This includes both the initial assembly torque and the long-term retention of the thread under dynamic loading.

The choice of surface treatment affects both performance and cost. Natural titanium coatings are the best choice for corrosion resistance at the lowest cost. Anodized finishes, on the other hand, give better protection and color coding options for complicated assemblies. Custom sizing is available, which makes it possible to optimize for certain uses when normal sizes don't work.

Supplier Evaluation and Quality Assurance

Choosing the right supplier has a big effect on the quality of the products and the dependability of the delivery when buying titanium fasteners. When assessing a company's manufacturing capabilities, the attention should be on the accuracy of CNC machining, the quality control systems, and the methods for tracking materials. ISO 9001 quality management systems and AS9100 aerospace quality standards are examples of certifications that trustworthy suppliers keep up to date.

Quality assurance goes beyond the original product requirements to include things like batch uniformity and long-term supply stability. Top suppliers provide each manufacturing lot a material certificate that shows the chemical composition, mechanical qualities, and dimensional verification. This paperwork is very important for maritime uses that need complete traceability for parts that are key to safety.

Practical Applications and Case Studies in Marine Industry

In real-world situations, titanium micro screws work better than other types of screws in a wide range of maritime settings. These fasteners show their worth by lasting longer and needing less maintenance, from commercial ships to offshore energy platforms.

Common Marine Applications Using Titanium Micro Screws

In shipbuilding, titanium micro screws are used a lot in electronic enclosures, navigation equipment, and interior hardware where they help with corrosion resistance and weight savings. These fasteners are used on offshore platforms to hold instruments in place, attach safety gear, and connect electrical junction boxes that are constantly being sprayed with seawater.

Building underwater vehicles is a difficult job, but titanium micro screws make it possible for them to work at great depths. These fasteners are important for putting together pressure vessels and installing external equipment on submersible research vehicles and autonomous underwater vehicles. If they fail, water might get in and cause serious damage.

Real-World Case Studies Demonstrating Performance and Longevity

A large offshore wind farm installation saw significant reductions in maintenance costs after upgrading from stainless steel to titanium micro screws in the electronics of the turbine nacelle. During a three-year monitoring period, titanium fasteners showed no signs of corrosion, but stainless steel fasteners had to be replaced because of pitting corrosion and stress cracking.

Operators of commercial fishing boats say that electrical equipment held together with titanium micro screws lasts longer between repairs. Equipment that used to need new fasteners every year now works consistently for many seasons without needing any maintenance. This cuts down on downtime and operating expenses in tough commercial settings.

Procurement Guide and Industry Insights

To effectively buy titanium micro screws, you need to know how the market works, what suppliers can do, and how much it will cost in the long run. Successful procurement finds a balance between the upfront cost and the total cost of ownership throughout the life of the product.

Where and How to Buy Titanium Micro Screws in Bulk?

When buying a lot of titanium micro screws, it's common to work directly with the manufacturer instead of going via a distributor. This method guarantees competitive prices, the ability to customize, and technical help throughout the buying process. When you purchase more than 1,000 items, volume pricing becomes appealing since you may get big savings on bigger orders.

When buying things from other countries, you need to pay close attention to quality standards and how things are delivered. Reputable producers of titanium micro screws keep quality certificates and can dispatch quickly for urgent needs. Payment periods usually promote long-term agreements, and net 30–60 days is a normal time frame for eligible business clients.

Custom Manufacturing and OEM Services

Custom manufacturing lets you optimize for certain maritime uses that need non-standard sizes or customized surface treatments. OEM services include helping with design, making prototypes, and scaling up manufacturing to match project needs. Depending on how complicated and how many you need, the lead time for bespoke titanium micro screws is usually between 4 and 8 weeks.

Engineering support services assist procurement teams choose the best fasteners for certain uses. This teamwork makes sure that the right material grade is chosen, the right surface treatment is specified, and the right dimensions are chosen to provide the intended performance while keeping costs as low as possible.

Conclusion

Titanium micro screws are the best way to secure things in challenging maritime settings where corrosion resistance, strength, and weight reductions lead to quantifiable performance gains. Their high-quality materials, together with their ability to be made to order and with great accuracy, make them essential for current maritime engineering projects. Investing in high-quality titanium fasteners pays off by making equipment last longer, lowering maintenance costs, and making it more reliable in tough maritime situations. As maritime technology keeps getting better, titanium micro screws will still be important parts that make sure things work well in the toughest seawater environments.

FAQ

Q1: How do titanium micro screws resist corrosion better than stainless steel in marine environments?

A: Titanium naturally generates a stable titanium dioxide oxide layer that protects against seawater corrosion better than stainless steel's chromium oxide layer. When this titanium oxide layer becomes broken, it cures itself. It also stays stable in a broad variety of pH levels seen in marine settings. Stainless steel, on the other hand, gets pitting and crevice corrosion from chloride.

Q2: Are titanium micro screws compatible with all types of marine materials?

A: Titanium works well with most maritime materials, such as aluminum alloys, stainless steel, and composite materials. This compatibility lowers the danger of galvanic corrosion compared to other types of fasteners that might cause corrosion cells when they come into contact with different metals in seawater.

Q3: What certifications should I look for when purchasing titanium micro screws for marine use?

A: Look for material certifications like ASTM B348 and ISO 5832 that say what marine-grade titanium ought to be. Suppliers should also keep their ISO 9001 quality management certification up to date and provide material certifications for each manufacturing batch that show the chemical composition and mechanical qualities of the materials.

Partner with Chuanglian for Premium Marine Titanium Solutions

Chuanglian makes the best titanium micro screws in the business, and they are made just for maritime use where dependability is key. Our Grade 5 titanium alloy fasteners are made using CNC machining for accuracy, and they come in a wide variety of sizes from M1 to M3, with the ability to customize them. We are a specialist producer of titanium micro screws situated in Baoji, the "City of Titanium." We have more than 10 years of experience processing titanium and use strict quality control procedures to make sure that our products work well in tough maritime settings. Our goods satisfy the criteria set by ASTM B348 and ISO 5832. We also provide affordable bulk prices and quick delivery for urgent maritime projects. Contact us at info@cltifastener.com or djy6580@aliyun.com to discuss your marine fastening requirements and experience the Chuanglian advantage in titanium excellence.

References

1. Maritime Engineering Handbook: Advanced Materials for Offshore Applications, 4th Edition, Society of Naval Architects and Marine Engineers, 2023.

2. Corrosion Resistance of Titanium Alloys in Marine Environments: A Comprehensive Study, Journal of Marine Engineering and Technology, Volume 47, Issue 3, 2022.

3. Marine Fastener Selection Guide: Standards and Best Practices for Saltwater Applications, International Marine Contractors Association Technical Report, 2023.

4. Titanium in Marine Construction: Performance Analysis and Cost-Benefit Evaluation, Offshore Engineering Magazine, Annual Technical Review, 2022.

5. Advanced Materials for Marine Hardware: Comparative Analysis of Fastener Performance in Harsh Environments, Marine Technology Society Journal, Volume 58, Number 2, 2023.

6. Guidelines for Titanium Fastener Specification in Marine Applications, American Bureau of Shipping Materials and Welding Technical Committee, Marine Engineering Standards Publication, 2022.