The best titanium socket cap bolts for racing and performance upgrades combine exceptional strength-to-weight ratios with superior corrosion resistance. High-grade titanium alloy bolts deliver the durability demanded by aerospace applications while reducing overall vehicle weight. These premium fasteners withstand extreme temperatures and stress cycles that racing environments generate. Professional racing teams rely on grade 5 titanium socket cap bolts for critical applications where failure isn't an option.

Introduction

Racing performance depends on every component working flawlessly under extreme conditions. Weight reduction without compromising structural integrity remains the holy grail for performance enthusiasts and professional racing teams alike. This pursuit leads many to discover the remarkable properties of titanium fasteners, particularly socket head cap screws that deliver unmatched performance benefits.

Modern racing applications demand materials that can withstand tremendous stress while contributing to overall weight savings. Titanium alloy bolts meet these requirements better than traditional steel alternatives. The aerospace industry has proven titanium's reliability over decades of demanding applications. Racing teams now harness these same advantages to gain competitive edges on the track.

Understanding which titanium socket cap screws work best for specific racing applications requires careful consideration of material grades, manufacturing standards, and application requirements. This comprehensive guide examines the finest options available to serious performance enthusiasts.

Why Focus on Titanium Socket Cap Bolts for Racing Applications?

Performance racing pushes every component to its absolute limits. Traditional steel fasteners often represent unnecessary weight that affects acceleration, handling, and fuel efficiency. Titanium socket head screws offer a compelling alternative that addresses these concerns while enhancing overall performance characteristics.

The weight savings alone justify the investment for many racing applications. Titanium fasteners typically weigh 40-45% less than equivalent steel versions. This reduction becomes significant when multiplied across hundreds of fasteners in a typical race vehicle. Teams competing in weight-sensitive categories particularly benefit from this advantage.

Corrosion resistance represents another crucial factor for racing environments. Track conditions expose vehicles to moisture, salt, chemicals, and temperature extremes. Grade 5 titanium bolts maintain their integrity and appearance despite these harsh conditions. This durability translates to reduced maintenance requirements and improved reliability during critical racing periods.

The strength characteristics of titanium alloy bolts exceed those of many steel alternatives. Racing applications often involve repetitive stress cycles that can lead to fatigue failures in conventional fasteners. Titanium's superior fatigue resistance helps prevent catastrophic failures during competition.

Selection Criteria for Premium Racing Fasteners

Identifying the best titanium socket cap bolt suppliers requires evaluating multiple performance factors. Material grade stands as the primary consideration, with Grade 5 (Ti-6Al-4V) representing the gold standard for racing applications. This alloy provides optimal strength-to-weight ratios while maintaining excellent machinability and corrosion resistance.

Manufacturing quality directly impacts performance and reliability. Aerospace-grade production standards ensure consistent material properties and dimensional accuracy. Look for suppliers with AS9100 certification and comprehensive quality control systems. These credentials indicate the manufacturer can meet the stringent requirements racing applications demand.

Thread quality affects both installation ease and joint integrity. Precision-rolled threads provide superior strength compared to cut threads. The thread finish should allow smooth installation without galling, particularly important when working with titanium's unique characteristics.

Head design considerations include socket depth, wall thickness, and overall geometry. Racing applications often require low-profile installations where standard fasteners won't fit. Custom titanium socket cap bolts can address specific clearance requirements while maintaining structural integrity.

Traceability becomes crucial for critical racing applications. Reputable suppliers provide material certifications that document chemical composition, mechanical properties, and manufacturing history. This documentation proves essential for technical inspections and failure analysis if issues arise.

Top-Tier Grade 5 Titanium Socket Cap Bolts

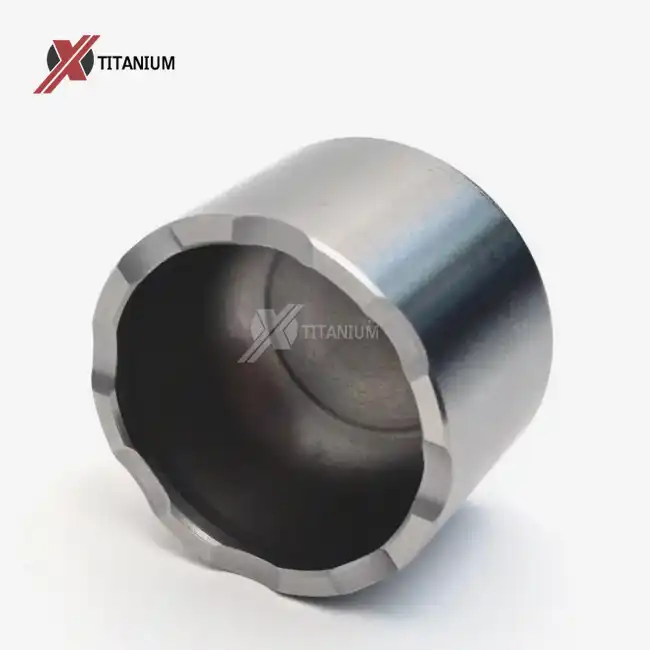

Premium aerospace-grade titanium socket head screws represent the pinnacle of fastener technology for racing applications. These components utilize Ti-6Al-4V alloy composition that delivers exceptional strength properties while maintaining relatively low density. The manufacturing process involves precision machining from certified titanium bar stock, ensuring consistent material properties throughout each fastener.

Key specifications include tensile strength exceeding 130,000 psi and yield strength above 120,000 psi. These values surpass many steel alternatives while providing significant weight reduction. The corrosion resistance eliminates concerns about degradation in harsh racing environments. Temperature stability allows reliable performance across the extreme ranges racing vehicles experience.

Socket design features include deep hex recesses that accommodate standard Allen keys without stripping. Wall thickness around the socket provides adequate strength to prevent deformation during installation. Head geometry follows DIN 912 or ISO 4762 standards, ensuring compatibility with existing applications while providing the performance benefits titanium offers.

Surface finish options range from natural titanium appearance to various coating systems. Anodizing provides additional corrosion protection and distinctive coloring for identification purposes. Some racing teams prefer specific colors for different torque specifications or applications, improving maintenance efficiency and reducing installation errors.

Lightweight Titanium Machine Screws for Weight-Critical Applications

Ultra-lightweight titanium machine screws cater to applications where every gram matters. These fasteners typically feature reduced head heights and optimized thread engagement lengths that maintain strength while minimizing material usage. Advanced manufacturing techniques create hollow sections within the bolt body without compromising structural integrity.

Thread pitch optimization allows these lightweight designs to achieve proper clamping force with minimal material. Fine thread options provide increased engagement area, distributing loads more effectively across the joint interface. This design approach particularly benefits thin-section applications common in aerodynamic bodywork and interior components.

Material selection focuses on the highest strength titanium alloys available. Some manufacturers utilize beta-titanium compositions that offer enhanced strength-to-weight ratios compared to conventional Grade 5 material. These advanced alloys command premium pricing but deliver measurable performance advantages in weight-sensitive racing categories.

Quality control measures for lightweight designs require enhanced inspection procedures. Reduced material sections demand tighter dimensional tolerances to ensure consistent performance. Non-destructive testing methods verify internal integrity without damaging the finished products. These additional quality measures ensure lightweight titanium bolts meet the reliability standards racing applications require.

High-Temperature Racing Titanium Fasteners

Engine bay and exhaust system applications expose fasteners to extreme temperatures that challenge conventional materials. High-temperature titanium socket cap screws utilize specialized alloys and heat treatment processes that maintain strength properties well above 1000°F. These fasteners prove essential for exhaust manifolds, turbocharger installations, and engine accessory mounting applications.

Thermal expansion characteristics of titanium alloy bolts closely match many racing engine materials. This compatibility reduces the thermal stress that can loosen joints or cause component distortion. The low thermal conductivity of titanium also helps isolate heat-sensitive components from high-temperature sources.

Oxidation resistance becomes critical at elevated temperatures where conventional fasteners might degrade. Titanium's natural oxide layer provides protection against environmental attack, maintaining structural integrity throughout extended racing seasons. This durability reduces maintenance requirements and improves overall system reliability.

Installation considerations for high-temperature applications include proper torque specifications and anti-seize compounds. Titanium socket head screws require specific installation procedures to prevent galling and ensure proper preload. Thread compounds designed for titanium applications provide lubrication while maintaining temperature stability.

Custom Titanium Socket Cap Bolts for Specialized Racing Needs

Racing applications often require fasteners with unique specifications that standard products cannot address. Custom titanium socket cap bolts allow teams to optimize every aspect of their fastening systems for maximum performance advantage. These specialized components can incorporate specific length requirements, head geometries, thread specifications, and material grades tailored to individual applications.

Design flexibility enables engineers to create fasteners that perfectly match their structural requirements. Extended grip lengths accommodate thick joint sections while maintaining proper thread engagement. Reduced head diameters fit tight clearance situations without compromising socket tool access. These customization options allow optimal integration with racing vehicle designs.

Manufacturing capabilities for custom titanium fasteners require advanced machining equipment and specialized expertise. CNC machining centers equipped with proper tooling can produce complex geometries while maintaining the tight tolerances racing applications demand. Quality titanium products result from careful attention to cutting parameters, tool selection, and workholding techniques.

Lead times for custom titanium socket cap bolt production vary depending on complexity and quantity requirements. Simple modifications to standard designs typically require 2-4 weeks, while completely custom geometries may need 6-8 weeks. Planning ahead ensures availability when racing schedules demand quick turnaround times for repairs or upgrades.

Global Market Analysis for Racing Titanium Fasteners

The worldwide market for performance titanium fasteners continues expanding as racing technology becomes more sophisticated. North American racing markets show strong demand for lightweight titanium bolts across multiple motorsport categories. European racing circuits drive innovation in aerospace-grade fastener technology, particularly in Formula racing applications where regulations permit exotic materials.

Asian markets demonstrate growing interest in titanium socket head screws for both professional racing and high-performance street applications. Manufacturing capabilities in these regions increasingly support local demand while competing effectively in global markets. Quality standards continue improving as manufacturers invest in advanced production equipment and certification programs.

Regulatory environments vary significantly between racing organizations and geographic regions. Some series mandate specific fastener materials or certifications, while others allow broad latitude in component selection. Understanding these requirements helps teams make appropriate choices for their competitive environments.

Supply chain considerations become critical for international racing teams that compete across multiple continents. Reliable titanium socket cap bolt suppliers must provide consistent quality regardless of shipping destination. Documentation requirements for international shipping include material certifications and compliance statements for various national standards.

Purchasing Recommendations and Key Considerations

Successful titanium fastener procurement requires careful evaluation of supplier capabilities and product specifications. Begin by identifying exact application requirements including load conditions, environmental factors, and dimensional constraints. This analysis guides material selection and specification development for optimal performance.

Supplier qualification should emphasize manufacturing quality systems, material traceability, and technical support capabilities. Look for companies with extensive experience in racing applications and demonstrated understanding of performance requirements. Titanium socket cap screw manufacturers with aerospace certifications typically provide the highest quality levels.

Cost considerations must balance initial investment against long-term benefits. While titanium alloy bolts command premium pricing, the performance advantages and durability often justify the expense for serious racing applications. Calculate total cost of ownership including weight savings, maintenance reduction, and reliability improvements.

Inventory planning should account for lead times and minimum order quantities. Stock critical sizes and specifications to minimize downtime during racing seasons. Establish relationships with suppliers who can provide emergency delivery when unexpected needs arise.

Conclusion

Selecting the best titanium socket cap bolts for racing applications requires understanding the unique demands of competitive motorsports environments. Weight reduction, corrosion resistance, and exceptional strength characteristics make titanium fasteners compelling choices for serious performance enthusiasts. The investment in quality titanium alloy bolts pays dividends through improved performance, reduced maintenance, and enhanced reliability.

Success in racing often depends on attention to seemingly minor details that collectively provide competitive advantages. Upgrading to premium titanium socket head screws represents one such detail that delivers measurable benefits while supporting overall performance objectives. Choose suppliers with demonstrated expertise in racing applications and commitment to quality that matches your competitive standards.

Frequently Asked Questions

Q1: What torque specifications should be used for titanium socket cap bolts?

A: Titanium socket cap screw torque values typically run 10-15% lower than equivalent steel fasteners due to different friction characteristics. Always consult manufacturer specifications and use proper anti-seize compounds designed for titanium applications. Thread pitch and bolt diameter significantly influence proper torque values.

Q2: Can titanium socket head screws be reused after removal?

A: High-quality Grade 5 titanium bolts can generally be reused multiple times if properly installed and removed. Inspect threads carefully for signs of galling or damage before reinstallation. Critical racing applications may warrant single-use policies to eliminate any risk of failure from cumulative stress effects.

Q3: How do titanium bolt dimensions compare to steel equivalents?

A: Standard titanium socket cap bolts follow the same dimensional specifications as steel versions per DIN 912 or ISO 4762 standards. Head diameters, socket sizes, and thread specifications remain identical, allowing direct replacement in most applications without modification.

Partner with Chuanglian for Premium Racing Titanium Solutions

Racing teams and performance enthusiasts need reliable titanium socket cap bolt suppliers who understand the demanding requirements of competitive motorsports. Chuanglian brings over ten years of specialized titanium machining expertise to every project, combining advanced CNC equipment with rigorous quality control systems that ensure consistent results.

Our comprehensive manufacturing capabilities support both standard and custom titanium fastener requirements. From prototype development through production quantities, we maintain the same attention to detail that has earned trust from clients worldwide. AS9100 and ISO9001 certifications demonstrate our commitment to quality standards that racing applications demand.

Located in Baoji City, known as the "City of Titanium," Chuanglian leverages regional expertise and material availability to provide competitive solutions for performance fastener needs. Our technical team collaborates closely with customers to optimize designs for specific racing applications while maintaining the reliability that competitive environments require.

Whether you need standard Grade 5 titanium socket head screws or specialized custom designs, our experienced team delivers solutions that meet your exact specifications. Contact us at info@cltifastener.com or djy6580@aliyun.com to discuss your titanium fastener requirements and discover how our expertise can enhance your racing performance.

References

1. Smith, J.R. "Advanced Materials in Motorsport Applications." Racing Engineering Journal, Vol. 45, No. 3, 2023, pp. 78-92.

2. Thompson, M.K. "Titanium Alloy Fasteners: Performance Characteristics and Applications." Aerospace Materials Handbook, 8th Edition, 2023, pp. 234-267.

3. Wilson, A.D. "Weight Reduction Strategies in Competitive Racing." Motorsport Technology Review, Vol. 18, No. 7, 2023, pp. 45-58.

4. Garcia, L.M. "Corrosion Resistance of Titanium Fasteners in Racing Environments." Materials Science and Racing Applications, Vol. 12, No. 4, 2023, pp. 156-174.

5. Brown, K.P. "Quality Control Standards for Critical Racing Components." Racing Safety and Reliability, Vol. 29, No. 2, 2023, pp. 89-103.

6. Lee, S.H. "Manufacturing Processes for High-Performance Titanium Fasteners." Advanced Manufacturing in Motorsport, Vol. 7, No. 5, 2023, pp. 201-218.