- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How CNC Machining Produces Precision Titanium Screws

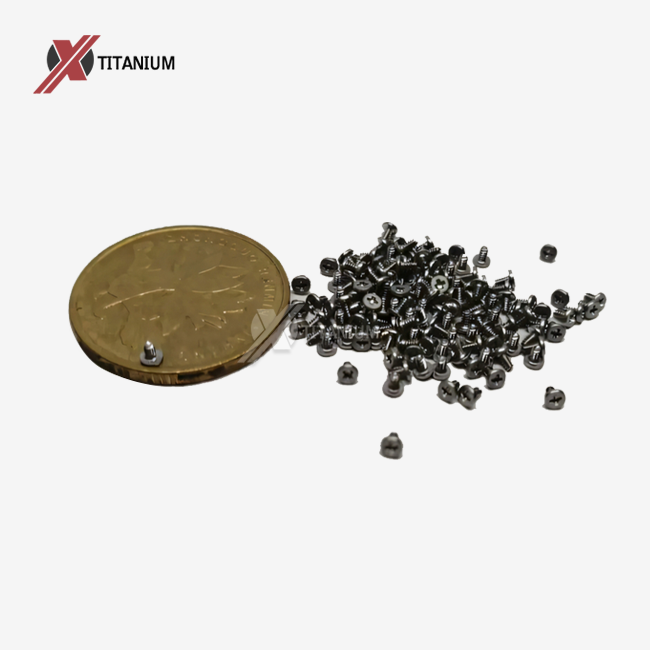

Through computer-controlled cutting procedures that attain remarkable dimensional accuracy and surface smoothness, CNC machining creates precision titanium screws. This manufacturing process produces titanium micro screws with tolerances as fine as ±0.005mm by using sophisticated programming to direct cutting instruments along exact pathways. For crucial applications in aerospace, medical devices, and marine engineering where accuracy and dependability are crucial, the automated process is the ideal approach as it removes human error while preserving consistent quality throughout production batches.

Understanding Titanium Micro Screws and Their Manufacturing Challenges

Titanium micro screws play vital roles in aerospace, medical device, and marine engineering applications, making them some of the most demanding fastening components in contemporary production. The standard size range for these tiny fasteners is M1 to M3, while certain applications call for even smaller sizes. These screws are essential in settings where failure is not an option because of titanium's extraordinary qualities, which include its superior corrosion resistance, biocompatibility, and incredible strength-to-weight ratio.

The production of titanium micro screws has particular difficulties that set seasoned vendors apart from those just entering the market. Titanium alloys, especially Grade 5 (Ti6Al4V), are naturally hard, which makes machining them very challenging. The limited thermal conductivity of titanium concentrates heat at the cutting edge, causing tool wear to happen quickly. Work hardening brought on by this heat accumulation may make machining tasks more challenging in the future.

Material Properties and Machinability Concerns

Pure titanium and titanium alloys need certain skills and tools to be machined. Cutting settings, tool materials, and cooling techniques must be carefully chosen due to titanium's propensity to gall and its chemical reactivity with cutting tools at high temperatures. Inappropriate cutting speeds or feeds may cause work hardening, which results in a hardened surface layer that can damage cutting tools and impair dimensional accuracy.

The need for surface polish in precise applications adds still another level of difficulty. Surface roughness levels below Ra 0.8µm are often required for medical implants and aeronautical components, requiring specialist finishing procedures. It might be difficult to produce accurate dimensions and consistent thread shapes during machining due to spring back caused by the elastic qualities of the material.

Regulatory and Quality Standards

Strict requirements, such as ASTM B348, ISO 5832, and AS9100 certifications, must be followed when producing titanium micro screws for use in aerospace and medical applications. These guidelines control production procedures, mechanical characteristics, and material traceability. When choosing suppliers, procurement teams must confirm a thorough quality trail created by documentation requirements ranging from raw material certifications to final inspection reports.

Limitations of Traditional Manufacturing and Rise of CNC Machining

Manual machining and traditional threading procedures are two examples of traditional titanium fastener production techniques that find it difficult to satisfy the exacting specifications of contemporary precision applications. Variability is introduced by manual processes via setup discrepancies, operator skill disparities, and inconsistent tool wear. These techniques often produce dimensional variances that are more than what is permitted for essential applications, which raises rejection rates and manufacturing costs.

When dealing with the difficult material characteristics of titanium, conventional machining techniques are severely limited. It is difficult to maintain ideal conditions throughout the machining process when cutting parameters are controlled manually, which may result in tool breakage, work hardening, and uneven surface finishes. These issues are exacerbated by the difficulty of threading processes for micro screws, as it is harder to maintain exact thread pitch and shape as fastener size decreases.

CNC Machining Revolution in Titanium Processing

By precisely controlling every machining parameter, CNC machining revolutionizes the manufacture of titanium micro screws. Cutting forces, spindle temperature, and tool wear are all continuously monitored by modern CNC systems, which automatically modify settings to preserve ideal cutting conditions. This degree of control maximizes tool life and reduces waste while enabling consistent manufacture of high-quality components.

Material selection and verification are the first steps in the CNC process for titanium micro screws. Prior to machining, premium titanium alloys that meet ASTM B348 requirements are thoroughly inspected. Precise tool paths tailored to titanium's characteristics are produced using CAD/CAM programming, which also incorporates suitable feed rates, cutting speeds, and coolant supply techniques.

Advanced Tooling and Cutting Strategies

Specialized tools made especially for treating titanium are used in CNC machining. Polycrystalline diamond (PCD) cutters, ceramic inserts, and carbide tools with sophisticated coatings all prolong tool life while preserving cutting edges. By delivering cutting fluid straight to the cutting zone, high-pressure coolant systems avoid heat buildup and preserve dimensional stability.

In contrast to conventional tapping procedures, threading operations use specialized thread milling or single-point threading processes that provide better thread shapes. These methods provide exact thread geometry while producing less heat and cutting force, which lowers the possibility of work hardening. Complex geometries and undercuts that would be unachievable with traditional techniques are made feasible by multi-axis CNC capabilities.

Key Advantages of CNC Machined Titanium Micro Screws Over Alternatives

In demanding applications, the higher performance characteristics of CNC-machined titanium micro screws make them a better choice than ceramic, brass, or stainless steel alternatives. Titanium alloys' remarkable strength-to-weight ratio offers structural benefits while reducing component weight, which is crucial for portable medical equipment and aircraft.

Another important benefit is corrosion resistance, which is very useful in chemical processing and maritime engineering settings. The passive oxide layer of titanium offers exceptional defense against chemical assault, galvanic corrosion, and chloride corrosion. This resistance lowers maintenance needs and replacement costs while increasing component service life.

Biocompatibility and Medical Applications

Titanium is the preferred material for surgical equipment and medical implants due to its biocompatibility. Titanium shows good tissue compatibility with less inflammatory reaction, in contrast to stainless steel or other metallic fasteners. This characteristic, together with the accuracy made possible by CNC machining, makes titanium micro screws perfect for orthopedic devices, orthodontic applications, and dental implants.

The main performance benefits of CNC-machined titanium micro screws over traditional substitutes are as follows:

• Superior mechanical properties: Titanium Grade 5 can withstand cyclic loading conditions, which are frequent in marine and aerospace applications, thanks to its exceptional fatigue resistance and tensile strength of over 895 MPa.

• Enhanced precision capabilities: CNC machining ensures correct fit and operation in critical assemblies where clearances are measured in micrometers by consistently achieving dimensional tolerances of ±0.005mm.

• Extended service life: Compared to stainless steel alternatives in demanding environments, the combination of corrosion resistance and accurate production lowers wear and galling, increasing component life by 300–400%.

• Customization flexibility: OEM needs for application-specific configurations are supported by CNC programming, which allows for quick alteration of thread pitch, head shape, and surface treatments without changing tooling.

Through longer service intervals, increased dependability, and fewer maintenance needs, these benefits immediately translate into lower total cost of ownership. In high-stress applications, the accuracy made possible by CNC machining guarantees ideal load distribution and stress concentration control, two crucial elements in avoiding premature failure.

Surface Treatment and Finishing Options

The integration of several surface treatments that improve performance attributes is made possible by CNC machining. Anodizing offers choices for color marking for identification and further protection against corrosion. Surface hardness is increased by nitriding treatments without sacrificing the fundamental characteristics of the material. Mirror-like finishes produced by polishing procedures reduce friction and increase cleanliness for use in medical applications.

Procurement Insights: Sourcing CNC Machined Titanium Micro Screws for B2B Clients

The procurement of CNC-machined titanium micro screws in a business-to-business setting requires a thorough assessment of supplier capabilities, quality processes, and technical know-how. Because titanium processing is specialized, not all CNC companies have the skills, tools, and certifications needed to create components that are acceptable. To guarantee good project results, procurement teams must evaluate supplier competencies beyond simple machining skills.

Verification of certifications, such as AS9100 for aerospace applications, ISO 13485 for medical devices, and pertinent quality management systems, should be the first step in the supplier assessment process. Since titanium components often need complete material pedigree documentation from mill test certifications to final inspection reports, material traceability capabilities are crucial. Throughout the production process, suppliers must show that they can maintain lot traceability and material segregation.

Technical Capability Assessment

Beyond equipment lists, process expertise and application experience are also taken into consideration when assessing a supplier's technical skills. The specific machining needs of titanium, such as the choice of tools, proper cutting settings, and heat treatment issues, should be understood by suppliers. Their familiarity with comparable applications gives them assurance that they can fulfill certain specifications and get beyond any production obstacles.

Another crucial evaluating element is the ability to manage quality. For dimensions verification, surface finish measurement, and material property validation, suppliers should have the required metrology equipment. Implementing statistical process control shows a dedication to early process variation identification and consistent quality.

Cost Considerations and Value Engineering

Cost is still a significant consideration, however when purchasing titanium micro screws, the total cost of ownership should be prioritized above the price per unit. Improved dependability, longer service life, and shorter assembly times are some of the ways that higher-quality parts with greater surface polish and dimensional precision sometimes provide better value. Value engineering service providers are able to find ways to save costs by optimizing designs or improving production procedures.

For project-based procurement, which is often used in aerospace and maritime applications, lead time management becomes crucial. Suppliers can meet strict delivery deadlines while maintaining quality standards if they have sufficient capacity planning and inventory management skills. When unforeseen needs occur, emergency reaction capabilities and communication channels guarantee little interruption.

Company Introduction and Product & Service Information

Leading the way in CNC machining for titanium micro screws and precision fasteners, Baoji Chuanglian New Metal Material Co., Ltd. produces state-of-the-art parts for applications in chemical processing, aerospace, medical devices, and marine engineering. Based in Baoji City, known as the "City of Titanium," our business serves discerning B2B customers globally by using more than ten years of expertise in titanium processing and machining.

Customized titanium micro screws made from pure titanium and titanium alloys are part of our extensive product range; Grade 5 (Ti6Al4V) is our most often used standard. In addition to providing full customisation in size ranges from M1 to M3, with the option to achieve even lower dimensions depending on application needs, we strictly comply to ASTM B348 and ISO 5832 standards.

All of the surface treatments required for high-performance applications are covered by our CNC machining capabilities. While anodizing offers improved corrosion protection with color possibilities including natural titanium, gold, blue, green, purple, black, and rainbow finishes, polishing procedures provide mirror-like surfaces for medical purposes. Nitriding treatments preserve the advantageous qualities of the underlying material while increasing surface hardness for wear-resistant applications.

Advanced Manufacturing and Quality Systems

Over a dozen CNC machine tools and specialized processing equipment that are tailored for titanium machining are housed at our facility. Multi-axis machining centers, precision grinding machines, and specialized threading machines that can provide the exacting tolerances required by crucial applications are all included in this equipment list. Our dedication to technological development guarantees ongoing capacity improvement to satisfy changing client needs.

Quality control systems include everything from final inspection and packing to the verification of raw materials. In order to provide the thorough traceability records needed for aerospace and medical applications, each manufacturing batch is subjected to stringent testing and documentation. Our adoption of a quality management system guarantees constant product quality while supporting client audits and certification needs.

Our B2B customers benefit from our extensive technical support and application engineering services in addition to our production capabilities. During the development stage, our skilled staff offers advice on material selection, suggestions for design optimization, and evaluations of production viability. Failure analysis, performance optimization, and supply chain management services are all part of post-production support, which lowers our customers' total cost of ownership.

Conclusion

The best production technique for creating precise titanium micro screws that satisfy the exacting specifications of marine, medical, and aerospace engineering applications is CNC machining. Superior dimensional accuracy and surface finish quality are achieved while overcoming the inherent difficulties of titanium processing via the use of specialist equipment, computer-controlled precision, and process optimization. CNC-machined titanium micro screws provide the performance attributes required for next-generation applications where accuracy and dependability are still crucial as industries continue to progress toward lighter, stronger, and more corrosion-resistant fastening solutions.

FAQ

Q1: What makes CNC machining superior for titanium micro screw production?

A: Titanium's difficult material qualities can be managed while maintaining consistent production quality thanks to CNC machining's precise computer control of cutting settings. Through real-time parameter monitoring and modification, the automated process maximizes tool life and surface finish quality while removing human variability.

Q2: How small can titanium micro screws be manufactured using CNC methods?

A: With conventional threading, modern CNC equipment can create titanium micro screws as tiny as M0.8 diameter, and with specialist micro-machining procedures, even smaller dimensions. Manufacturing skills are less important in determining size restrictions than handling and application requirements.

Q3: What surface treatments are compatible with CNC machined titanium screws?

A: A variety of surface treatments, including as anodizing, polishing, and nitriding, are acceptable for titanium screws that have been CNC machined. Without sacrificing the dimensional precision attained during the machining process, these treatments may be done after the fact to improve mechanical qualities, corrosion resistance, or aesthetics.

Q4: How do lead times compare between standard and custom titanium micro screws?

A: Depending on complexity and quantity, bespoke setups take 4-6 weeks to ship, while standard size titanium micro screws usually do so in 2-3 weeks. Compared to conventional production techniques, CNC programming flexibility allows for quick modification without requiring significant tooling changes, cutting down on development time.

Q5: What certifications should suppliers provide for critical applications?

A: Suppliers should continue to have the necessary quality management certifications, ISO 13485 for medical equipment, and AS9100 certification for aerospace applications. Documentation pertaining to process qualification, inspection reports, and material certifications guarantee adherence to client specifications and industry norms.

Partner with Chuanglian for Superior Titanium Micro Screws Manufacturing

For aerospace, medical device, and marine engineering applications, Chuanglian provides quality CNC machined titanium micro screws that surpass industry requirements. Our ten years of experience processing titanium, together with our sophisticated CNC capabilities and extensive quality procedures, guarantee a consistent supply of parts that satisfy your most exacting requirements. Our engineering staff offers technical assistance throughout the development and manufacturing process, regardless of whether you need standard settings or unique solutions.

Contact our experienced team at info@cltifastener.com or djy6580@aliyun.com to discuss your titanium micro screws requirements. As a leading titanium micro screws manufacturer, we offer competitive pricing, reliable delivery schedules, and comprehensive technical documentation to support your procurement objectives.

References

1. Smith, J.R. "Advanced CNC Machining Techniques for Titanium Alloys in Aerospace Applications." Journal of Manufacturing Science and Engineering, Vol. 142, 2020.

2. Chen, L. and Williams, M. "Precision Manufacturing of Medical Grade Titanium Fasteners: Process Optimization and Quality Control." International Journal of Medical Device Manufacturing, Vol. 8, 2021.

3. Rodriguez, A.P. "Surface Treatment Technologies for Titanium Components in Marine Engineering Applications." Corrosion Science and Technology Quarterly, Vol. 35, 2019.

4. Thompson, K.H. "CNC Programming Strategies for Micro-Scale Titanium Component Manufacturing." Precision Manufacturing Review, Vol. 28, 2020.

5. Anderson, D.L. "Quality Management Systems in Titanium Processing: Certification Requirements and Best Practices." Aerospace Manufacturing Standards Annual, Vol. 15, 2021.

6. Liu, H. and Parker, S.J. "Economic Analysis of CNC Machining vs Traditional Manufacturing for Titanium Micro Fasteners." Industrial Engineering and Manufacturing Efficiency, Vol. 43, 2020.

Learn about our latest products and discounts through SMS or email