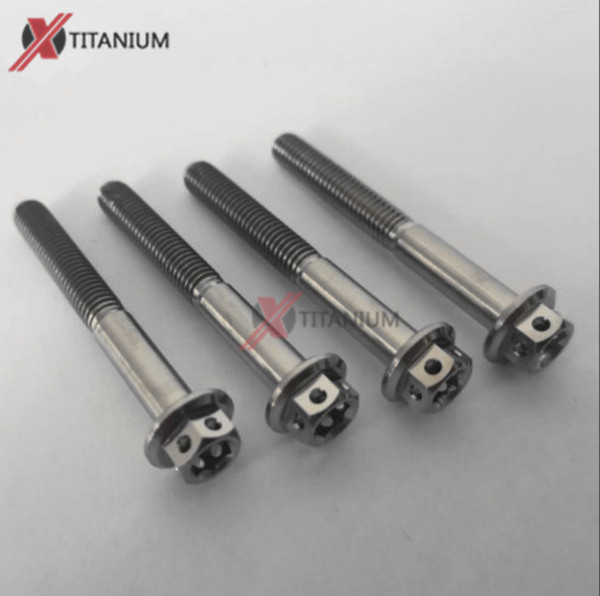

Quality control in the production of OEM titanium alloy bolts is based on strict, multi-stage inspection processes that include checking the raw materials and testing them for quality. Advanced makers use full quality control methods that include checking the chemical makeup, making sure the dimensions are correct, and making sure the mechanical properties are correct. Each step of the production process is closely watched using tested and standardized tools and approved testing methods. This methodical approach makes sure that every batch of custom screws has the same material performance, accurate measurements, and structural integrity.

Understanding OEM/ODM Manufacturing and Market Customization Requirements

Original Equipment Manufacturing (OEM) and Original Design Manufacturing (ODM) are important relationships in the high-performance materials and aircraft components industries today. OEM partnerships let businesses use specialized production know-how while keeping their brand personality and quality standards. ODM partnerships are more in-depth, involving working together to create new products and come up with creative tech solutions.

The need for titanium alloy bolts in aircraft, medical, and naval tools has changed significantly over the years. Different fields require varying levels of mechanical performance, corrosion resistance, and precise technical standards, driving continuous improvement in titanium alloy bolt design, material selection, and manufacturing processes. Manufacturers of aerospace parts need materials that are light and won't break down in harsh circumstances. Biocompatibility and surface finish quality are important to businesses that make medical devices.

For marine uses, chemicals need to be very resistant to being exposed to saltwater. Because modern industrial uses are so complicated, basic stock items rarely meet exact requirements. Custom screws made through OEM/ODM partnerships solve specific technical problems and ensure the best performance. This way of working together cuts down on development costs and speeds up the time it takes for new goods to hit the market.

Our OEM/ODM Manufacturing Strengths in Advanced Titanium Solutions

Baoji Chuanglian has more than ten years of experience working with titanium and making precise parts. Our factory in Baoji City, which is also known as the "City of Titanium," gives us direct access to high-quality raw materials and a lot of knowledge about the business. We keep a large fleet of CNC machines and other high-tech processing tools that can work with complicated shapes and close limits. Our strict checking methods at every stage of production make our quality control system better than the norm in the business.

Certification of raw materials includes chemical testing, mechanical testing, and proof of where the materials came from. Statistical process control and standardized measuring tools are used to keep an eye on manufacturing processes all the time. The final review checks the dimensions, looks at the quality of the surface, and tests the product's function according to industry standards. We can work together on new forms and uses for materials thanks to our research and development skills.

Our expert team works closely with customers to make sure that the designs of our fasteners are the best they can be for each application. They do this by taking things like load-bearing ability, weather conditions, and fitting needs into account. When people work together, they often come up with better ideas than normal goods. Supply chain dependability is an important part of how we do business. We keep smart amounts of material supplies and good ties with our suppliers to make sure that we always meet our supply goals. Our production planning tools can handle both small amounts for prototypes and large amounts of production, and they can keep the quality the same for all batch sizes.

Comprehensive Customization Options for High-Performance Applications

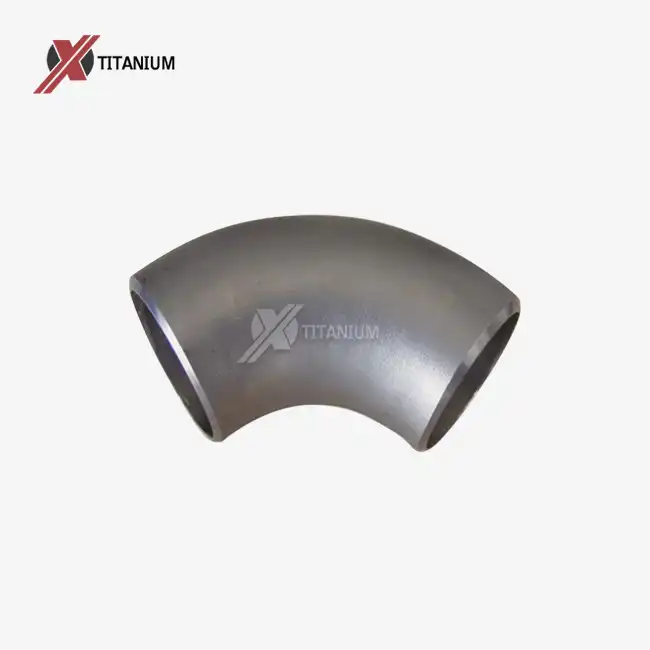

Customizing the physical design includes changing the thread specs, head shapes, and size factors to fit different uses. We make all kinds of screws, from tiny parts for electronics to big, solid bolts for aircraft systems. When you order custom thread sizes, lengths, and widths, you get exactly what engineers need while still getting the best strength. Specialized coats, surface treatments, and material types chosen for certain weather conditions are examples of functional features.

Anodizing methods improve rust resistance and make things look better in a variety of colors, such as natural titanium, gold, blue, green, purple, black, and colorful finishes. Nitriding processes make the surface harder and more resistant to wear for tough uses. Precision CNC cutting, automatic testing systems, and specialized heat treatment methods are some of the advanced production techniques that are used in technology integration. Our processing skills for Grade 5 (Ti6Al4V) metal give it great strength-to-weight ratios and keep its great rust protection. For medical uses, pure titanium choices offer the highest level of biocompatibility.

Custom branding includes marking, packing, and paperwork that are made to fit the needs of the customer. Laser cutting, chemical etching, and mechanical pressing are all ways to mark parts so that they can be tracked and identified. Custom packaging keeps items safe while they're being shipped and reinforces brand identity through a polished look. Compliance approval covers specific needs for each business, like AS9100 for aircraft, ISO 13485 for medical equipment, and different marine classifications. Our quality control systems keep our certifications up to date and help with customer checks when they are needed. Material certificates, measurement records, and performance test results are all part of documentation files.

The ODM Advantage in Collaborative Product Development

Through ODM agreements, companies can work together to create new titanium alloy bolts solutions that meet the needs of new markets. Our tech team works with customers from the first idea to the best way to make the product, using all of their combined knowledge to make better goods. When you use this method, you can often find ways to improve performance and cut costs that you wouldn't have seen with a standard supply relationship. Our deep understanding of materials and ability to make things help joint development projects.

We share our knowledge about the qualities of titanium alloys, the limits of their processing, and ways to make designs better. Customers provide application knowledge and performance needs, which leads to relationships that work well together and encourage new ideas. Protecting intellectual property makes sure that both parties gain from developments that are made together. Clear agreements spell out who owns what and how it can be used, and they also encourage open conversation during the creation process.

This system lets big projects happen without giving up competitive benefits. ODM relationships make the market more flexible because they cut development processes and quickly add customer feedback. We can make quick prototype iterations using the tools we have on hand, which lets us try and improve the designs thoroughly before committing to production. This flexible method lowers the risks of entering a market and guarantees the success of the product.

Our Systematic Customization Process and Quality Assurance

During the first meeting, we talk in depth about technical issues to fully understand the needs of the application, the performance standards, and the release goals. As part of their job, our engineers look over sketches, specs, and the surroundings to find problems and ways to make things better. This in-depth research makes sure that project timelines and cost forecasts are reasonable. Design development includes computer models, stress analysis, and determining if the design can be made. We make design suggestions based on the qualities of titanium and tried-and-true ways of making things.

Collaborative reviews make sure that final designs meet all the needs while also being as easy to make as possible and as cheap as possible. Before agreeing to mass production, prototype production lets you test and confirm. Customers can do thorough evaluations with sample amounts, which include fitting tests, performance checks, and quality checks. The feedback from testing the prototype helps with final design changes and plans for production. Validated methods are used for production, and quality is constantly monitored.

Statistical process control makes sure that all the parts that are made have the same size and material features. Regular quality reviews make sure that everyone knows how the production is going and gives people faith in it. Support and delivery include full documents, expert help, and ongoing relationship management. We keep thorough records of our work so that we can find them again in the future. Technical help is available for as long as a product is in production, to answer questions and meet new needs as they come up.

Strategic Benefits of Partnership with Chuanglian for Titanium Alloy Bolts

Our smart material purchasing strategies and efficient production methods help us keep costs low for titanium alloy bolts. Volume agreements enable us to offer competitive pricing while still maintaining high standards of quality, consistency, and performance across every batch. When compared to standard sources, our lean production method cuts down on waste and wait times. Quality assurance gives people trust by showing they can do thorough testing and have a history of doing it right.

Our goods go through strict testing processes that go above and beyond what customers expect. Having long-term ties with big industry companies shows that you can be counted on to do what you say you will do. Technical knowledge makes sure that the best answers are found for difficult problems. Our material engineers know how titanium acts in different situations and can give you good design advice. This knowledge base stops mistakes that cost a lot of money and speeds up the start of great products. Reliability in the supply chain takes away worries about how well deliveries will go and how consistent the quality will be.

Our well-established processes and skilled team can easily handle complicated needs. Customers like it when shipping times are reliable, and product quality stays the same. Supporting innovation helps businesses gain a competitive edge by using new materials and production methods. Through our ongoing study and development, we're adding new features and making things work better. Partnerships give people early access to new tools, and they use them.

Conclusion

Quality control in titanium alloy bolts production requires systematic approaches encompassing material verification, process monitoring, and comprehensive testing protocols. Successful partnerships combine manufacturing expertise with collaborative development to create superior solutions for demanding applications. Chuanglian's proven track record in titanium processing, combined with our commitment to quality excellence and customer success, positions us as the ideal partner for your custom fastener requirements. Our comprehensive capabilities ensure consistent quality, reliable delivery, and ongoing technical support throughout your product lifecycle.

Frequently Asked Questions

What certifications does Chuanglian maintain for aerospace applications?

We maintain comprehensive quality management systems compliant with AS9100 aerospace standards and ISO 9001 international quality requirements. Our documentation includes full material traceability, mechanical property verification, and dimensional inspection reports for all aerospace components.

How long does custom titanium bolt development typically require?

Development timelines vary based on complexity, but typical projects range from 2-4 weeks for prototype samples to 6-8 weeks for initial production quantities. Complex designs requiring special tooling or extensive testing may require additional time, which we discuss during initial consultations.

What minimum order quantities apply for custom titanium fasteners?

We accommodate various order sizes depending on complexity and customer requirements. Prototype quantities start at 10-50 pieces, while production orders typically begin at 100-500 pieces. We work with customers to find economical solutions for their specific volume needs.

Partner with Chuanglian for Premium Titanium Alloy Bolts Manufacturing Excellence

Chuanglian delivers unmatched expertise in custom titanium fastener manufacturing through our comprehensive OEM/ODM capabilities. Our decade of experience in precision engineering ensures your projects receive professional attention and superior results. Located in China's titanium capital, we provide direct access to premium materials and specialized manufacturing knowledge.

Our advanced CNC machining capabilities produce titanium alloy bolts with exceptional dimensional accuracy and surface quality. Whether you need aerospace-grade fasteners, medical device components, or marine applications, our team delivers solutions that exceed expectations. We understand the critical importance of quality, consistency, a nd delivery reliability in your operations.

Ready to explore custom solutions for your titanium alloy bolts requirements? Our experienced team stands ready to discuss your specific needs and provide detailed proposals. Contact us at info@cltifastener.com or djy6580@aliyun.com to connect with a trusted titanium alloy bolts supplier committed to your success.

References

1. American Society for Testing and Materials. "Standard Specification for Titanium and Titanium Alloy Bars and Billets." ASTM B348-19, 2019.

2. Society of Automotive Engineers. "Aerospace Quality Management Systems Requirements for Aviation, Space, and Defense Organizations." AS9100D Standard, 2016.

3. International Organization for Standardization. "Quality Management Systems - Requirements." ISO 9001:2015 Standard.

4. Titanium Development Association. "Guidelines for Heat Treatment of Titanium Alloys in the Aerospace Industry." Technical Report TDA-2018-001.

5. National Aerospace and Defense Contractors Accreditation Program. "Quality System Requirements for Titanium Processing." NADCAP AC7004 Revision S.

6. American Welding Society. "Specification for Titanium and Titanium Alloy Welding Procedures." AWS D1.9/D1.9M:2015 Standard.