Grasping the Composition and Properties of Gr5 Titanium Bicycle Screws

Chemical Composition of Grade 5 Titanium

Gr5 titanium bicycle screws are crafted from an alloy known as Ti-6Al-4V, which is composed of titanium with 6% aluminum and 4% vanadium. This specific composition contributes to the screws' exceptional strength and performance characteristics. The addition of aluminum enhances the alloy's strength-to-weight ratio, while vanadium improves its overall strength and heat resistance.

Mechanical Properties of Gr5 Titanium

The mechanical properties of Gr5 titanium bicycle screws are truly impressive. Beyond their high tensile strength, these screws exhibit excellent fatigue resistance, making them ideal for components subjected to repeated stress cycles. They also possess a yield strength of about 828 MPa (120,000 psi) and an elastic modulus of approximately 114 GPa. These properties ensure that the screws can withstand significant loads without permanent deformation, maintaining their structural integrity over time.

Corrosion Resistance and Durability

One of the standout features of Gr5 titanium bicycle screws is their exceptional corrosion resistance. Titanium naturally forms a protective oxide layer when exposed to air, making it highly resistant to various forms of environmental corrosion. This characteristic is particularly valuable in bicycle applications, where components are often exposed to moisture, sweat, and other potentially corrosive elements. The durability of these screws ensures long-lasting performance and reduces the need for frequent replacements.

Advantages of Using Gr5 Titanium Bicycle Screws in Cycling Applications

Weight Reduction and Performance Enhancement

The use of Gr5 titanium bicycle screws offers significant weight savings compared to traditional steel alternatives. With a density of only 4.43 g/cm³, titanium is about 45% lighter than steel. This weight reduction, while seemingly small for individual screws, can add up to a noticeable difference when applied across multiple components on a bicycle. The resulting decrease in overall bike weight can lead to improved acceleration, better handling, and enhanced climbing performance - crucial factors for competitive cyclists and enthusiasts alike.

Fatigue Resistance and Longevity

Gr5 titanium bicycle screws excel in their ability to withstand repeated stress cycles without failure. This high fatigue resistance is particularly important in cycling, where components are subjected to constant vibrations and cyclical loads. The longevity of these screws not only ensures consistent performance over time but also reduces the frequency of maintenance and replacements, making them a cost-effective choice in the long run.

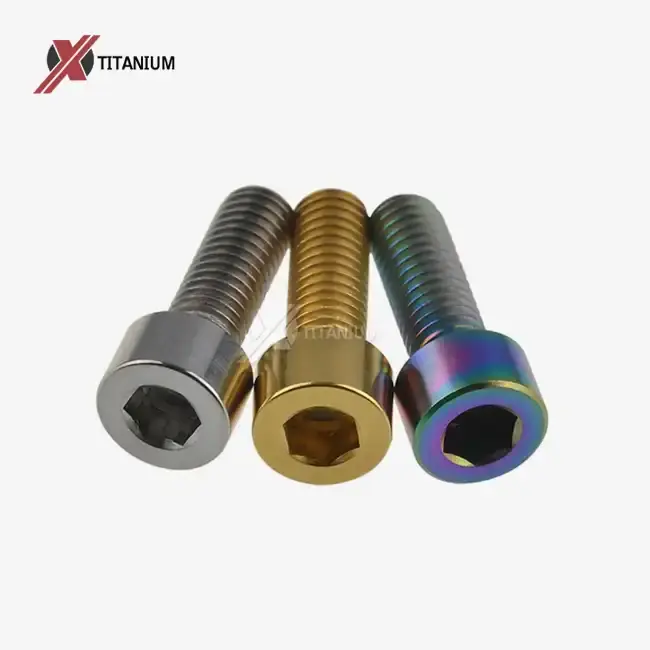

Biocompatibility and Aesthetic Appeal

An often-overlooked advantage of Gr5 titanium bicycle screws is their biocompatibility. This property makes them ideal for use in areas where direct skin contact may occur, reducing the risk of allergic reactions or skin irritation. Additionally, titanium screws can be anodized to produce a range of attractive colors without compromising their structural integrity. This allows for customization options that can enhance the overall aesthetic appeal of a bicycle while maintaining the screws' exceptional performance characteristics.

Comparing Gr5 Titanium Bicycle Screws to Other Materials

Titanium vs. Steel: Strength-to-Weight Ratio

When comparing Gr5 titanium bicycle screws to their steel counterparts, the most significant difference lies in the strength-to-weight ratio. While high-quality steel screws can match or even exceed the absolute strength of titanium, they do so at a much higher weight cost. Gr5 titanium offers a superior strength-to-weight ratio, allowing for strong, durable components that contribute less to the overall weight of the bicycle. This characteristic is particularly valuable in performance-oriented cycling disciplines where every gram counts.

Titanium vs. Aluminum: Durability and Longevity

Aluminum screws are sometimes used as a lightweight alternative to steel, but they fall short when compared to Gr5 titanium bicycle screws in terms of durability and longevity. While aluminum is indeed lighter than titanium, it lacks the strength and fatigue resistance of Gr5 titanium. Aluminum screws are more prone to stripping, deformation, and fatigue failure over time, especially when subjected to high stresses or frequent adjustments. Gr5 titanium screws, on the other hand, maintain their structural integrity and performance characteristics for much longer periods, even under demanding conditions.

Cost Considerations and Long-Term Value

It's important to acknowledge that Gr5 titanium bicycle screws typically come with a higher initial cost compared to steel or aluminum alternatives. However, this higher upfront investment often translates to better long-term value. The exceptional durability, corrosion resistance, and fatigue strength of titanium screws mean they need to be replaced less frequently. Additionally, their ability to maintain optimal performance over extended periods can contribute to better overall bicycle performance and reduced maintenance costs in the long run. For cyclists who prioritize quality, performance, and longevity, the investment in Gr5 titanium bicycle screws can be well justified.

Conclusion

Gr5 titanium bicycle screws represent a pinnacle of engineering in cycling components. Their remarkable strength, combined with lightweight properties, corrosion resistance, and durability, make them an excellent choice for high-performance bicycles. While the initial cost may be higher than traditional materials, the long-term benefits in terms of performance, longevity, and reduced maintenance often outweigh this factor.

As cycling technology continues to evolve, Gr5 titanium screws remain at the forefront, offering a perfect balance of strength, weight savings, and reliability. For those interested in exploring the benefits of Gr5 titanium bicycle screws or other titanium components for their cycling needs, don't hesitate to reach out to us at info@cltifastener.com or djy6580@aliyun.com. Our team of experts is always ready to provide detailed information and assist you in finding the perfect titanium solutions for your bicycle.