Titanium components significantly improve durability through their exceptional strength-to-weight ratio, superior corrosion resistance, and outstanding fatigue performance across demanding industrial applications. Titanium micro screws exemplify these advantages, offering biocompatibility for medical devices and mechanical reliability for aerospace applications, making them essential fastening solutions where traditional materials fail to meet stringent performance requirements and long-term reliability standards.

Understanding Titanium Micro Screws and Their Role in Enhancing Durability

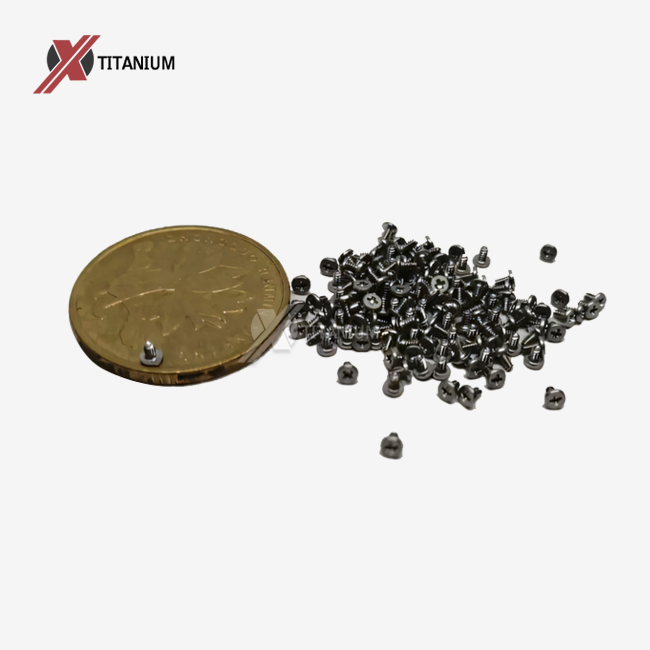

Titanium micro screws are a revolutionary new way to secure things with precision. They are very strong and work well in important situations. These unique parts have changed the requirements for production in fields where performance can't be compromised.

Primary Applications Across Critical Industries

Medical uses are the most common for titanium micro screws, and biocompatibility is still the most important factor. Orthopedic implants use these fasteners to hold bones together, whereas dental applications use them because they help bones grow together. In avionics systems and structural parts where weight loss and corrosion resistance are important, the aircraft industry uses titanium micro screws. Petrochemical processing equipment, naval gear, and high-performance electronics are all examples of industrial uses. Titanium's unique mix of being lightweight and having great mechanical qualities makes it useful for all applications. It lasts a long time even in harsh situations.

Key Material Properties Driving Superior Performance

The strength-to-weight ratio of titanium micro screws is around 40% better than that of steel, although the tensile strength is about the same. This benefit makes it possible to cut a lot of weight without hurting the structure. These fasteners are perfect for marine and chemical processes because they withstand corrosion better than stainless steel in chloride situations. Fatigue resistance means that titanium micro screws can handle millions of stress cycles without breaking. This is very important for aeronautical and medical uses where replacing them would be too expensive.

The Science Behind Titanium's Strength and Durability in Micro Screws

To understand why titanium is so strong, you need to look at both the makeup of the alloy and the ways it is made that improve its performance.

Titanium Grades and Their Mechanical Characteristics

Grade 5 titanium (Ti-6Al-4V) is the most common alloy used for micro screws. It has a tensile strength of more than 900 MPa and is quite ductile. This alpha-beta alloy has the best blend of strength and workability, which makes it perfect for CNC machining operations needed to make precise micro screws. Grade 2 titanium is better for medical use since it is more biocompatible, but it is weaker and more resistant to corrosion. The choice of grade depends on the needs of the application. For example, Grade 5 is better for mechanical applications that put a lot of stress on the material, while Grade 2 is better for medical implants.

Design Considerations for Load Distribution and Strength Optimization

The shape of the threads has a big effect on how the load is spread out in titanium micro screws. Fine-pitch threads spread stress out more evenly than coarse threads, which lowers stress concentration and extends the life of the material. The configuration of the head affects how torque is transferred and prevents the material from changing shape during installation. Sizes M1 to M3 work for a wide variety of applications, and bespoke sizes are available for more specific needs. Anodizing and nitriding are two types of surface treatments that make parts more resistant to wear and give them unique color codes to help you identify them.

Biocompatibility and Sterilization Methods

The oxide layer that forms on titanium makes it biocompatible because it stops ions from escaping into living systems. Sterilization technologies that work with gamma radiation, electron beam, and steam autoclave procedures make sure that medical uses satisfy regulatory standards without damaging the materials.

Comparative Analysis: Titanium Micro Screws vs. Other Materials

When choosing materials for micro fasteners, you need to carefully think about their performance, cost, and the needs of the individual application. This study helps procurement professionals make decisions more clearly.

Performance Comparison with Stainless Steel

Micro screws made of stainless steel are cheaper at first, however they don't hold up as well against corrosion in chloride conditions. Titanium is 50% lighter than stainless steel and is better for medical use since it is more biocompatible. Long-term cost study supports titanium since it lasts longer and needs less maintenance. The magnetic characteristics are quite different: titanium is not magnetic, yet stainless steel has a little magnetic attraction. This property is very important for medical equipment that work with MRI and for sensitive electronic uses.

Ceramic and Bioresorbable Alternative Evaluation

Ceramic micro screws are quite biocompatible, although they are not very strong. Ceramics are not good for high-stress uses since they are far less impact-resistant than titanium. Bioresorbable compounds can hold things in place for a short time, but they can't match titanium's long-lasting strength. Cost-effectiveness research shows that titanium is a good choice since it lasts longer, has to be replaced less often, and works better in a variety of industrial settings.

Procurement Guide: Sourcing Durable Titanium Micro Screws for Your Business

To successfully buy titanium micro screws, you need to know what suppliers can do, what quality standards they have, and what customization possibilities they provide that will help your project succeed in the long run.

Supplier Evaluation and Certification Requirements

ASTM B348 and ISO 5832 are two examples of quality certification standards that make sure materials can be traced and that they work the same way every time. AS9100 certification shows that a company can manage quality in the aerospace industry, while ISO 13485 accreditation shows that a company can make medical devices. When evaluating a supplier, you should look into their CNC machining skills, surface treatment choices, and testing facilities. Quality control systems must include the batch traceability and material certification paperwork that regulated sectors need.

Customization Options and Technical Specifications

Custom titanium micro screws may meet your specific needs by having different thread patterns, head shapes, and surface treatments. There are several anodizing possibilities, such as natural titanium, gold, blue, green, purple, black, and rainbow finishes, to meet both aesthetic and practical needs. Processing capabilities include CNC machining, polishing, anodizing, and nitriding, all of which make parts more resistant to wear and corrosion. Custom size ranges that go beyond the conventional M1-M3 requirements serve particular applications that need unique dimensional characteristics.

Logistics and Supply Chain Considerations

Minimum order numbers usually show how specialized the manufacture of titanium micro screws is, however volume pricing is available for bigger orders. Lead times vary based on how complicated the modification is and how much manufacturing capacity is available right now. This means that project schedules need to be planned ahead of time. When managing inventory, you should take into consideration the fact that titanium prices might change and that having long-term relationships with competent suppliers can be good for business. Strategic alliances give you precedence when there aren't enough materials and better technical assistance.

Company Introduction and Product/Service Information

Baoji Chuanglian New Metal Material Co., Ltd. is a top maker and supplier of titanium goods. It is based in Baoji City, which is known as the "City of Titanium." We have more than 10 years of experience in developing titanium products and doing precise machining.

Manufacturing Capabilities and Quality Systems

We have a wide range of CNC machining capabilities, including many machine machines that are set up to make precise micro screws. Polishing, anodizing, and nitriding are all ways to modify the surface of a material. These techniques may provide titanium, gold, blue, green, purple, black, and rainbow finishes that seem natural and satisfy a wide range of needs. Quality control systems make sure that everything is checked carefully, from the time the raw materials are received until the completed product is delivered. Processing of Grade 5 (Ti-6Al-4V) titanium alloy fulfills ASTM B348 and ISO 5832 requirements. It has strong tensile strength and corrosion resistance, making it suitable for tough jobs.

Product Portfolio and Technical Support

We sell titanium micro screws in normal M1-M3 sizes, but we can also make them to fit your needs. Applications include aerospace, medical devices, maritime engineering, and chemical processing. These sectors are supported by full technical assistance and quick prototyping services. We work with aircraft manufacturers, medical device firms, and petrochemical processors throughout the world to show that we are committed to high quality and on-time delivery.

Conclusion

Titanium parts make things last longer because they are made of better materials, such as having an excellent strength-to-weight ratio, being very resistant to corrosion, and being able to handle a lot of stress. Titanium micro screws are a great example of these benefits in important fields including aircraft, medicine, and industry. The scientific basis for titanium's performance shows that it works better than other materials, and thorough procurement techniques make sure it works well in tough applications. To have a successful long-term collaboration in titanium component sourcing, you need to work with good suppliers that have the right certifications and technical skills.

FAQ

Q1: How do titanium micro screws compare to stainless steel in terms of durability?

A: Titanium micro screws outperform stainless steel in terms of corrosion resistance, weight savings of 50%, and fatigue life. Even if the initial expenditures are more, titanium is a superior long-term value since it lasts longer and needs less maintenance, especially in tough conditions.

Q2: What sterilization methods are compatible with titanium micro screws?

A: Titanium micro screws can withstand steam autoclave, electron beam sterilization, and gamma radiation without deteriorating the material. The stable oxide layer keeps the structure stable and biocompatible through the many times it has to be sterilized for medical use.

Q3: Are custom titanium micro screws available for specialized applications?

A: Custom titanium micro screws may be made to fit your exact needs, such as having different thread patterns, head shapes, and surface treatments. Anodizing choices provide both practical and cosmetic advantages, and CNC machining may make parts that are bigger or smaller than the usual M1-M3 sizes.

Partner with Chuanglian for Premium Titanium Micro Screws

Chuanglian makes titanium micro screws with exacting standards that last longer than expected in aerospace, medical, and industrial settings. Our Grade 5 titanium alloy parts are very strong for their weight, resist corrosion better than others, and can be fully customized with anodizing treatments and specific surface finishes. We are a reputable producer of titanium micro screws with more than 10 years of experience. We provide technical advice, quick prototyping, and dependable supply chain solutions. Enjoy the benefits of dealing with a recognized supplier that cares about quality. Contact us at info@cltifastener.com or djy6580@aliyun.com to discuss your titanium micro screw requirements and discover how our solutions enhance your application performance.

References

1.Peters, M., et al. "Titanium Alloys for Aerospace Applications." Advanced Engineering Materials, Vol. 5, No. 6, 2003, pp. 419-427.

2.Geetha, M., et al. "Ti based biomaterials, the ultimate choice for orthopaedic implants – A review." Progress in Materials Science, Vol. 54, No. 3, 2009, pp. 397-425.

3.Boyer, R.R. "An overview on the use of titanium in the aerospace industry." Materials Science and Engineering: A, Vol. 213, No. 1-2, 1996, pp. 103-114.

4.Niinomi, M. "Mechanical properties of biomedical titanium alloys." Materials Science and Engineering: A, Vol. 243, No. 1-2, 1998, pp. 231-236.

5.Rack, H.J. and Qazi, J.I. "Titanium alloys for biomedical applications." Materials Science and Engineering: C, Vol. 26, No. 8, 2006, pp. 1269-1277.

6.Banerjee, D. and Williams, J.C. "Perspectives on Titanium Science and Technology." Acta Materialia, Vol. 61, No. 3, 2013, pp. 844-879.