Titanium hardware is a new kind of technology for structural engineering that has altered industries all over the world. It is the finest option for many uses since it is incredibly robust, does not rust, and is light. The growing importance of titanium parts in tough structural applications comes from its amazing ability to keep working well in tough conditions while keeping the total system weight down. Titanium micro screws are particularly useful for fastening things since they have a greater tensile strength and are less prone to break down in the environment. These components are created with great care and provide procurement managers, engineers, distributors, and OEM clients in the aerospace, medical, marine, and chemical processing industries that require reliable fastening solutions for high-stakes applications considerable performance advantages.

Understanding Titanium Micro Screws and Their Role in Structural Strength

Titanium micro screws are very advanced fasteners that are noted for being strong, not rusting, and being light. These specific pieces come in varied sizes to meet the demands of different structures. Engineers may utilize thorough size recommendations to get the ideal proportions for what they require. These fasteners are particularly significant in sectors like medical implants, aeronautical engineering, and precision electronics manufacturing because they can maintain structures sturdy even when things go wrong.

What Are Titanium Micro Screws?

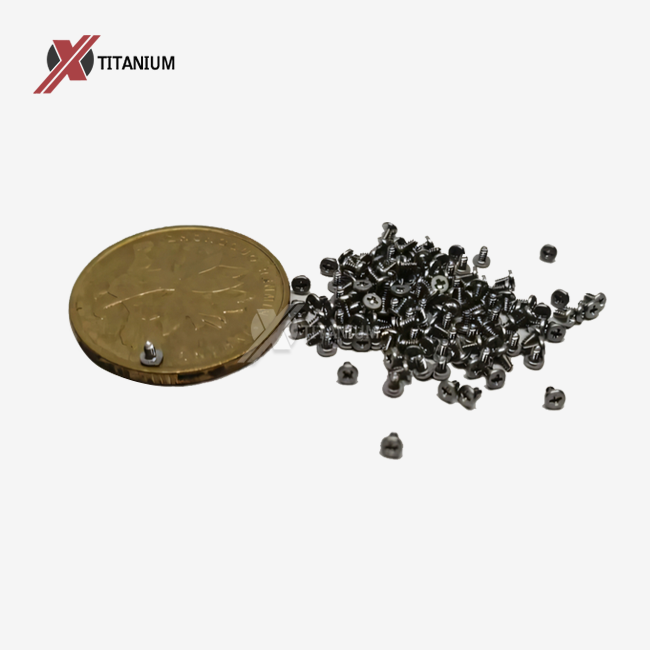

Titanium micro screws are high-quality titanium alloys that have been carefully made for use in situations where they need to be very strong and resistant to rust. In ordinary setups, these parts usually come in sizes M1 to M3. However, special sizes are easy to get for particular needs. The screws are made utilizing modern CNC machining methods that guarantee exact threading, uniform sizes, and a better surface polish.

Grade 5 titanium (Ti6Al4V) construction is a common requirement since it gives the best mechanical qualities for structural uses. Standards for manufacturing, such ASTM B348 and ISO 5832, make sure that the quality and performance of each batch is the same. Polishing, anodizing, and nitriding are some of the surface treatments that make the product further more resistant to corrosion and more visually appealing. The colors offered include natural titanium, gold, blue, green, purple, black, and rainbow finishes.

Benefits of Using Titanium Micro Screws in Structural Applications

The benefits of using titanium micro screws in structural applications go well beyond how strong they are. Here are the main reasons why these fasteners are great for tough jobs:

- Superior biocompatibility: Medical-grade titanium screws are very compatible with tissue, which makes them perfect for implant applications where long-term biological contact is needed

- Outstanding corrosion resistance: Titanium's natural oxide layer provides exceptional protection against acid, alkali, and saltwater environments, ensuring structural integrity over extended service periods

- Exceptional strength-to-weight ratio: Titanium offers strength comparable to steel while weighing approximately 40% less, reducing overall structural weight without compromising performance

- Temperature stability: These fasteners keep their mechanical qualities across a broad range of temperatures, so they may be used in aerospace and industrial settings

These benefits work together to solve important technical problems that conventional fasteners may not be able to. This gives procurement managers confidence in the long-term performance and dependability of the products.

Common Uses of Titanium Micro Screws Across Industries

Many industries that need strong and reliable structures employ titanium micro screws. These fasteners are highly crucial for putting together surgical tools in hospitals, as well as for orthopedic and dental implants. They are great for permanent implants since they are biocompatible and don't rust, which is vital for the safety of the patient and the durability of the implant over time.

Titanium micro screws are utilized in the aerospace and automobile sectors for structural elements, engine assembly, and light chassis work. The vehicle's performance and fuel efficiency are both better since it is powerful and light. Because they don't attract magnets and retain the same size, titanium fasteners are perfect for electronics and precise engineering. This is particularly true for fragile tools and assemblies that need to be very precise.

Titanium Micro Screws vs. Stainless Steel: Making the Right Material Choice

You need to know a lot about the pros and cons of titanium micro screws and stainless steel screws in order to select between them. Titanium is usually more resistant to corrosion, has a greater strength-to-weight ratio, and lasts longer, particularly in harsh situations where long-term stability is highly essential. In the real world, case studies from dentistry and orthopedics often reveal that titanium is superior than other materials for implant durability and long-term patient results.

Material Properties Comparison

There are a few key performance differences between titanium and stainless steel fasteners. Titanium is stronger than stainless steel in terms of tensile strength, but it is significantly less dense, which means it might lose up to 40% of its weight. Tests for corrosion resistance show that titanium remains strong while stainless steel begins to break down, particularly when there are a lot of acids or chlorides nearby.

Tests of longevity reveal that titanium fasteners preserve their mechanical properties for a long time, even when they are used to load and unload things over and over again. Titanium alloys are often superior at not becoming tired than stainless steel. This is why they are the greatest choice for parts that will be under stress cycles over and over again.

Case Studies: Structural Performance in Real-World Applications

Clinical investigations in dental implantology demonstrate that titanium microscrews have osseointegration rates of 95%, whereas their stainless steel counterparts achieve success rates of just 85-90%. Patients have less irritation and improved long-term stability since the materials are more biocompatible and resistant to corrosion.

Titanium fasteners are less likely to come loose when utilized in orthopedic surgery, and they help bones recover better than stainless steel implants. Tests done over a long period of time demonstrate that titanium components hold their form for decades, but stainless steel parts may need to be replaced because they rust or break down.

Cost vs. Value Analysis for Procurement Decisions

Even though titanium micro screws cost more than stainless steel ones, the total cost of ownership frequently advantages titanium since it needs less care and lasts longer. When procurement teams look at the long-term return on investment, they see that the initial premium pays out in the form of lower replacement costs, better dependability, and better performance.

The greater corrosion resistance means that you don't need to use protective coatings or check them often, which lowers the cost of continuous maintenance. In important situations where failure has serious effects, the reliability premium that comes with titanium fasteners is quite useful since it lowers the risk.

Criteria for Selecting Titanium Micro Screws for Structural Projects

When choosing the right titanium micro screws for structural projects, it's important to carefully consider the technical details, such as the grade of titanium, the possibilities for surface treatment, the size requirements, and the threading parameters. Grade 5 titanium (Ti6Al4V) is often the best choice since it is quite strong. Anodizing treatments, on the other hand, make the metal more resistant to corrosion and give it more cosmetic possibilities. Also, procurement managers need to check the credentials and quality certificates of suppliers to make sure that the products are always of high quality and meet all regulations.

Key Technical Metrics to Consider

Choosing a grade is a key part of specifying titanium fasteners. Compared to pure titanium, grade 5 titanium is stronger, which makes it perfect for applications that put a lot of stress on it. But pure titanium is better for medical uses where biological contact is a concern since it is more biocompatible.

Choosing the right surface treatment has a big effect on how well something works. Anodized finishes make surfaces more resistant to corrosion and look better, while nitriding treatments make surfaces harder so they may be used in applications where they need to be resistant to wear. Polished surfaces have less friction and are easier to clean, making them better for medical or food-grade uses.

Threading specs must be exactly what the application needs. Fine threads retain better in thin materials, whereas coarse threads are quicker to put together and less likely to become cross-threaded during installation.

Assessing Supplier Capabilities and Quality Certifications

Choosing certified suppliers makes guarantee that all manufacturing batches have the same quality and follow the rules. ISO 9001 quality management systems, AS9100 aerospace standards, and medical device certifications for healthcare applications are all important certifications. When evaluating a supplier, you should look at their production capabilities, quality control methods, and traceability systems.

OEM partnerships and customer references are great ways to find out how reliable and consistent a supplier's performance is. Long-term connections with established suppliers sometimes lead to cheaper prices, priority access to supplies when there aren't enough of them, and superior technical assistance.

Matching Screw Specifications to Application Needs

Custom manufacture lets you exactly adjust the parameters of fasteners to the needs of the application. Suppliers that provide CNC machining may make specialty threading, unusual head shapes, and dimensions that aren't conventional to fulfill particular technical needs.

When it comes to buying things, bulk purchase capabilities and minimum order quantity requirements are important, especially for applications that need a lot of them. Suppliers with flexible minimum order quantity (MOQ) rules can meet both prototype development and production needs, making it easy to go from development to manufacturing.

Procurement Best Practices for Titanium Micro Screws in B2B Markets

To get titanium micro screws quickly and easily, you need to strategically source them from reliable suppliers in major global marketplaces like the US, Europe, China, and India. To minimize problems with the supply chain and delays in projects, it is very important to look at a supplier's lead times, logistical capabilities, and dependability indicators. Negotiating good price structures with detailed contract conditions, such as volume discounts and after-sales assistance, improves overall procurement results and the value of long-term partnerships.

Sourcing Strategies and Supplier Selection

Global supplier networks provide different benefits based on the needs of the application and the location. American and European vendors usually provide high-quality goods with a lot of certificates. On the other hand, manufacturers in China and India sometimes offer low prices while quality standards are becoming better. When figuring up lead times, you need to think about both production schedules and overseas shipment procedures, especially for projects that need to be done quickly.

Supplier diversity techniques assist reduce risks in the supply chain while keeping prices competitive. Building partnerships with many competent suppliers gives you more flexibility in your purchases and more power in negotiations. It also makes sure that you have a steady supply even when the market changes or there are capacity issues.

Negotiating Pricing and Contract Terms

Knowing how price-per-piece structures and volume discount thresholds work helps you negotiate well for both small-scale prototype and large-scale manufacturing needs. Clear documentation of cost components and transparent pricing rules make it easier to establish budgets and manage costs over the life of a project.

After-sales service promises, such as technical assistance, fixing quality problems, and replacement policies, are worth a lot more than just the price of the item. Comprehensive contract conditions should include delivery timetables, quality requirements, and plans for what to do if supplies run out.

Ensuring Reliable Supply Chain and Quality Control

Quality certifications including medical-grade approvals, ISO standards, and industry-specific qualifications guarantee that products will always be of the same high quality and meet all rules. Before shipping, strong inspection and testing methods check the quality of the surface finish, the qualities of the materials, and the correctness of the dimensions.

Traceability systems make it possible to keep track of the sources of materials, the methods used to make them, and quality control data all the way through the supply chain. For regulated sectors that need detailed quality records and audit trails, this paperwork is quite important.

Chuanglian: Your Trusted Titanium Micro Screws Manufacturer

Baoji Chuanglian New Metal Material Co., Ltd. has been making titanium hardware for more than 10 years and makes high-quality micro screws that are perfect for tough structural applications in many sectors. We are based in Baoji City, which is known as the "City of Titanium." We use our strategic position and years of expertise to provide complete titanium solutions that fulfill the strict needs of aerospace, medical, petrochemical, and marine engineering applications.

About Chuanglian

Our firm is a tech-savvy and inventive business that focuses on researching, making, and precisely machining titanium and rare metal items. We have been making and developing titanium products for more than ten years, and we are currently a top supplier to well-known firms all over the globe. We invest in modern production capabilities and quality assurance processes because we are committed to always improving and making things better.

We provide a wide range of titanium products, including fasteners, rods, wire, plates, tubes, flanges, and other machined parts. We can be a single-source supplier for complicated projects that need a lot of titanium parts with the same high quality requirements since we have a wide range of products.

Our Product Range

We make our titanium micro screws to order from pure titanium and titanium alloys, including Grade 5 (Ti6Al4V) material for better strength. CNC machining procedures make sure that the dimensions are exact and the surface finish is of the highest quality. There are also a lot of surface treatment choices, like as polishing, anodizing, and nitriding, that improve the performance of the parts.

Our goods come in sizes from M1 to M3, and we can also make them to fit your needs. They fulfill the ASTM B348 and ISO 5832 requirements for quality assurance. You may choose from a natural titanium look or anodized hues like gold, blue, green, purple, black, and rainbow to fit your individual aesthetic and practical needs.

Why Partner with Chuanglian?

Our quality management system follows stringent national, international, and industry standards. This makes sure that the quality of our products stays the same from the time we get the raw materials until we deliver the final product. With our advanced CNC machine tools and mechanical processing equipment, we can fulfill a wide range of machining needs and have a full range of manufacturing capabilities.

Flexible minimum order quantities and competitive pricing make it possible to meet the needs of both prototype development and high-volume manufacturing. Efficient shipping and logistics throughout the globe make sure that time-sensitive projects get their deliveries on time.

Conclusion

Titanium hardware, especially precision-engineered titanium micro screws, makes structural strength much better in important areas including aircraft, medicine, marine, and industry. Titanium fasteners are the best option for demanding structural applications where performance dependability is very important since they have a great mix of high tensile strength, corrosion resistance, low weight, and biocompatibility. Strategic procurement choices that take into account quality certifications, supplier skills, and long-term value proposition lead to successful project results and operational excellence. Working with professional manufacturers like Chuanglian gives you access to high-quality titanium solutions that come with full technical support and established industry knowledge.

FAQ

Q1: What makes titanium micro screws better than stainless steel for structural applications?

A: Titanium micro screws are better than stainless steel because they are more resistant to corrosion, weigh 40% less, are more resistant to fatigue, and are more compatible with living things. Titanium has a far better strength-to-weight ratio than stainless steel, and it stays strong even in tough conditions where stainless steel may break down over time.

Q2: How do I determine the right size and grade of titanium micro screws for my project?

A: Think about the load needs of your application, the circumstances in which it will be used, and the rules that apply. Grade 5 titanium (Ti6Al4V) is the strongest kind of titanium for high-stress usage, although pure titanium is better for medical uses since it is more biocompatible. Use size tables and talk to knowledgeable vendors to make sure that the parameters meet your needs.

Q3: What are the typical lead times and MOQ requirements when ordering titanium micro screws in bulk?

A: Lead times usually vary from two to six weeks, depending on the specifications and the number of items needed. The minimum order quantities (MOQs) that suppliers set depend on the product and the provider. Many manufacturers have flexible MOQ policies for both prototype and production orders. Custom requirements may mean that tooling and setup take longer.

Partner with Chuanglian for Premium Titanium Micro Screws Solutions

Are you ready to improve your structural projects using high-quality titanium hardware? Chuanglian is the best choice for titanium micro screws for difficult applications since we have a lot of expertise making them, have strict quality control systems, and provide low prices. Our CNC-machined items are made of Grade 5 titanium and come with a variety of surface treatment choices. They are reliable and perform well, just like your projects need. Contact us at info@cltifastener.com or djy6580@aliyun.com to discuss your specific requirements, request detailed quotations, or explore custom manufacturing capabilities.

References

1. Boyer, R.R. "An overview on the use of titanium in the aerospace industry." Materials Science and Engineering: A, vol. 213, no. 1-2, 1996, pp. 103-114.

2. Niinomi, M. "Mechanical properties of biomedical titanium alloys." Materials Science and Engineering: A, vol. 243, no. 1-2, 1998, pp. 231-236.

3. Rack, H.J. and Qazi, J.I. "Titanium alloys for biomedical applications." Materials Science and Engineering: C, vol. 26, no. 8, 2006, pp. 1269-1277.

4. Lutjering, G. and Williams, J.C. "Titanium: Engineering Materials and Processes." Springer-Verlag Berlin Heidelberg, 2007.

5. Banerjee, D. and Williams, J.C. "Perspectives on Titanium Science and Technology." Acta Materialia, vol. 61, no. 3, 2013, pp. 844-879.

6. Peters, M., Kumpfert, J., Ward, C.H., and Leyens, C. "Titanium Alloys for Aerospace Applications." Advanced Engineering Materials, vol. 5, no. 6, 2003, pp. 419-427.