Understanding Titanium Torx Bolts: Strength Meets Versatility

What Sets Titanium Torx Bolts Apart?

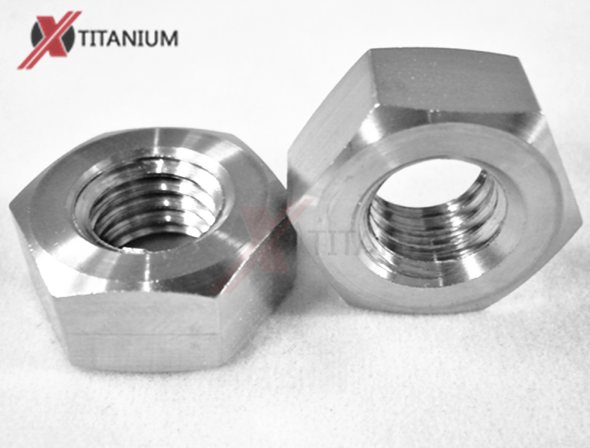

Titanium Torx bolts are a cut above the rest when it comes to fastening solutions. These bolts combine the exceptional properties of titanium with the unique design of Torx drive systems. Titanium, known for its remarkable strength-to-weight ratio, provides these bolts with unparalleled durability. The material's natural corrosion resistance makes it ideal for applications where exposure to moisture or chemicals is a concern.

The Torx drive, characterized by its six-pointed star shape, offers several advantages over traditional hex or Phillips head designs. This configuration allows for better torque transfer, reducing the risk of cam-out or stripping during installation or removal. The result is a fastener that's not only strong but also easier to work with, even in challenging conditions.

Key Benefits of Choosing Titanium Torx Bolts

Opting for titanium Torx bolts in your home repairs brings a host of benefits:

- Exceptional Strength: Titanium's high tensile strength ensures these bolts can withstand significant loads without failing.

- Corrosion Resistance: Unlike steel bolts that may rust over time, titanium bolts maintain their integrity even in harsh environments.

- Lightweight: The low density of titanium makes these bolts considerably lighter than their steel counterparts, which can be advantageous in weight-sensitive applications.

- Biocompatibility: For those with metal sensitivities, titanium's hypoallergenic properties make it a safe choice for use in living spaces.

- Temperature Resistance: Titanium maintains its properties across a wide range of temperatures, making it suitable for both indoor and outdoor applications.

These characteristics make titanium Torx bolts an excellent choice for long-lasting, high-quality home repairs that can withstand the test of time and environmental challenges.

Practical Applications: Where Titanium Torx Bolts Shine in Home Repairs?

Outdoor and High-Moisture Areas

Titanium Torx bolts excel in environments where traditional fasteners might succumb to corrosion. Their resistance to rust and degradation makes them ideal for:

- Deck Construction: Use titanium Torx bolts to secure deck boards and railings, ensuring longevity even in areas with high humidity or frequent rainfall.

- Outdoor Furniture Assembly: Create durable patio furniture that can withstand the elements year-round.

- Fence Installation: Secure fence posts and panels with bolts that won't weaken due to moisture exposure.

- Boat Repairs: For watercraft enthusiasts, these bolts offer excellent resistance to saltwater corrosion.

High-Stress Structural Applications

The strength of titanium Torx bolts makes them suitable for applications where structural integrity is paramount:

- Load-Bearing Joints: Use them in constructing or repairing load-bearing walls or support beams.

- Staircase Construction: Ensure the safety and stability of staircases by using titanium Torx bolts for securing treads and risers.

- Heavy Equipment Mounting: When installing large appliances or machinery, these bolts provide the necessary strength and reliability.

Specialized Home Improvements

Titanium Torx bolts can also be beneficial in more specialized home repair and improvement projects:

- Bathroom Renovations: Use them to install fixtures in high-moisture environments without worrying about rust.

- Kitchen Upgrades: Secure heavy countertops or install durable cabinet hardware.

- Home Gym Equipment: Ensure the safety and stability of exercise equipment with high-strength fasteners.

- Solar Panel Installation: Use corrosion-resistant bolts for mounting solar panels that will be exposed to the elements for years.

By choosing titanium Torx bolts for these applications, homeowners can ensure their repairs and improvements stand the test of time, reducing the need for frequent maintenance or replacement.

Best Practices for Installing Titanium Torx Bolts in Home Repairs

Preparation and Tool Selection

Before beginning your project with titanium Torx bolts, proper preparation is crucial:

- Select the Right Size: Choose the appropriate bolt diameter and length for your specific application. Titanium Torx bolts typically range from M3 to M12 sizes, with lengths varying from 6mm to 200mm.

- Use the Correct Driver: Ensure you have a Torx driver that matches the size of your bolt's head. Using the wrong size can damage the bolt or compromise the installation.

- Prepare the Surface: Clean and prepare the surface where the bolt will be installed. Remove any debris or old fasteners that might interfere with the new installation.

- Pre-drill When Necessary: For harder materials or to prevent splitting in wood, pre-drilling pilot holes can be beneficial. Use a drill bit slightly smaller than the bolt's diameter.

Installation Techniques

When installing titanium Torx bolts, follow these best practices to ensure optimal performance:

- Apply Anti-Seize Compound: To prevent galling (a form of wear caused by adhesion between sliding surfaces), apply a small amount of anti-seize compound to the bolt threads. This is particularly important when working with titanium fasteners.

- Avoid Overtightening: While titanium bolts are strong, overtightening can still cause damage. Use a torque wrench to achieve the proper tension without exceeding the bolt's limits.

- Ensure Proper Alignment: Before fully tightening, make sure the bolt is correctly aligned to prevent stress on the fastener and the materials being joined.

- Consider Using Washers: In some applications, using washers can help distribute the load and protect the surface material.

Maintenance and Inspection

To ensure the longevity of your titanium Torx bolt installations:

- Periodic Checks: Regularly inspect the bolts for any signs of wear or loosening, especially in high-stress or outdoor applications.

- Clean as Needed: While titanium is corrosion-resistant, keeping the area around the bolts clean can prevent the buildup of debris that might affect their performance.

- Retighten if Necessary: If you notice any loosening, carefully retighten the bolts to their original specifications.

- Monitor for Galvanic Corrosion: When using titanium bolts with dissimilar metals, be aware of the potential for galvanic corrosion and use appropriate isolation techniques if needed.

By following these best practices, you can maximize the benefits of using titanium Torx bolts in your home repairs, ensuring durable and long-lasting results.

Conclusion

Titanium Torx bolts offer a superior fastening solution for durable home repairs. Their unique combination of strength, corrosion resistance, and ease of use makes them an excellent choice for a wide range of applications, from outdoor projects to high-stress structural work. By understanding their properties, identifying suitable applications, and following best installation practices, homeowners can leverage these advanced fasteners to create long-lasting, high-quality repairs and improvements.

For those interested in exploring the use of titanium Torx bolts or seeking more information about titanium products for various applications, don't hesitate to reach out to industry experts. You can contact Baoji Chuanglian New Metal Material Co., Ltd. at info@cltifastener.com or djy6580@aliyun.com for professional advice and high-quality titanium solutions tailored to your specific needs.