The Unique Properties of Grade 5 Titanium Acorn Nuts

Unparalleled Strength-to-Weight Ratio

Grade 5 titanium acorn nuts boast an impressive strength-to-weight ratio that sets them apart from other fastening options. This characteristic is particularly crucial in industries where every gram counts, such as aerospace and automotive engineering. The Ti-6Al-4V alloy used in Grade 5 titanium offers a tensile strength comparable to steel but at nearly half the weight. This remarkable property allows manufacturers to reduce the overall weight of their products without compromising structural integrity.

In practical terms, the use of titanium acorn nuts can lead to significant fuel savings in aircraft and vehicles, as well as improved performance in racing applications. The reduced weight also translates to easier handling and installation, benefiting technicians and engineers working with these components.

Superior Corrosion Resistance

One of the most compelling reasons for the widespread adoption of Grade 5 titanium acorn nuts is their exceptional resistance to corrosion. Titanium naturally forms a protective oxide layer when exposed to air, making it highly resistant to various forms of chemical attack. This innate property is further enhanced in Grade 5 titanium, which contains small amounts of aluminum and vanadium, improving its already impressive corrosion resistance.

The corrosion-resistant nature of these acorn nuts makes them ideal for use in marine environments, chemical processing plants, and other settings where exposure to corrosive substances is a constant concern. Unlike steel fasteners that may rust or degrade over time, titanium acorn nuts maintain their integrity and appearance even in the harshest conditions, ensuring long-term reliability and reduced maintenance costs.

Temperature Tolerance and Thermal Stability

Grade 5 titanium acorn nuts exhibit remarkable thermal properties, maintaining their strength and structural integrity across a wide range of temperatures. This thermal stability is crucial in applications where components are subjected to extreme heat or cold, such as in aerospace or high-performance automotive systems.

The ability of these fasteners to withstand high temperatures without losing their mechanical properties makes them invaluable in engine components and exhaust systems. Conversely, their performance at cryogenic temperatures ensures reliability in space applications or industrial processes involving extremely low temperatures. This versatility across temperature ranges contributes significantly to their status as the industry standard.

Applications and Industries Benefiting from Grade 5 Titanium Acorn Nuts

Aerospace and Aviation

The aerospace industry has been at the forefront of adopting Grade 5 titanium acorn nuts. In aircraft construction, every component must meet stringent safety standards while contributing to overall efficiency. Titanium acorn nuts excel in this environment due to their high strength-to-weight ratio, which allows for robust connections without adding unnecessary weight to the aircraft.

These fasteners are commonly used in critical areas such as engine mounts, wing attachments, and landing gear assemblies. Their resistance to fatigue and ability to withstand the extreme temperature variations encountered during flight make them indispensable in modern aircraft design. Moreover, the corrosion resistance of titanium acorn nuts ensures longevity and reliability, even when exposed to diverse environmental conditions encountered during global operations.

Automotive and Racing

In the automotive industry, particularly in high-performance and racing applications, Grade 5 titanium acorn nuts have gained significant traction. The weight reduction offered by these fasteners can have a noticeable impact on vehicle performance, especially in competitive racing where every fraction of a second counts.

Titanium acorn nuts are often used in suspension systems, engine components, and exhaust assemblies. Their ability to withstand high temperatures and resist loosening under vibration makes them ideal for these demanding applications. In addition, the corrosion resistance of titanium is particularly beneficial in protecting against road salts and other corrosive substances encountered in everyday driving conditions.

Marine and Offshore Applications

The marine environment is notoriously harsh on metal components, with constant exposure to saltwater and varying temperatures. Grade 5 titanium acorn nuts have proven to be exceptionally well-suited for marine applications due to their outstanding corrosion resistance. They are frequently used in boat and ship construction, as well as in offshore oil and gas platforms.

In these settings, titanium acorn nuts are employed in hull fittings, deck equipment, and underwater structures. Their resistance to seawater corrosion ensures long-term reliability and reduces the need for frequent maintenance or replacement. This durability translates to lower lifecycle costs and improved safety in marine operations.

Manufacturing and Quality Control of Grade 5 Titanium Acorn Nuts

Precision Machining Techniques

The production of Grade 5 titanium acorn nuts requires advanced manufacturing techniques to ensure precision and consistency. Computer Numerical Control (CNC) machining is typically employed to achieve the tight tolerances and complex geometries required for these high-performance fasteners. The machining process must be carefully controlled to prevent work hardening of the titanium alloy, which can affect its mechanical properties.

Specialized cutting tools and cooling techniques are often used to optimize the machining process for titanium. This attention to detail in manufacturing ensures that each acorn nut meets the exacting standards required for critical applications. The result is a product that combines precise dimensions with the inherent strength and lightweight properties of Grade 5 titanium.

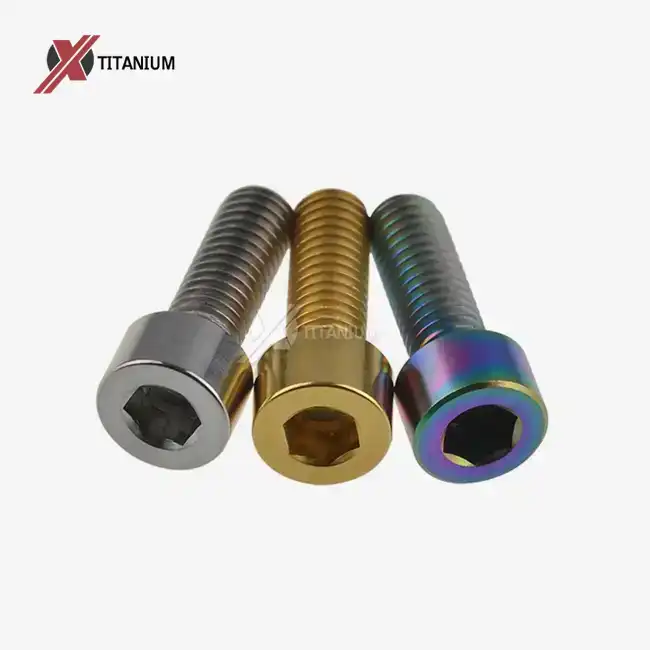

Surface Treatment and Finishing

While Grade 5 titanium naturally possesses excellent corrosion resistance, various surface treatments can be applied to enhance its properties further or achieve specific aesthetic results. Anodizing is a common treatment that can improve wear resistance and create a range of color options, from the natural titanium hue to gold, blue, purple, or black finishes.

Other surface treatments, such as nitriding, can be used to increase the surface hardness of titanium acorn nuts, improving their wear resistance in high-friction applications. These treatments not only enhance the functional properties of the fasteners but also allow for customization to meet specific industry or design requirements.

Quality Assurance and Testing Protocols

Ensuring the reliability and performance of Grade 5 titanium acorn nuts requires rigorous quality control measures. Manufacturers typically implement comprehensive testing protocols that may include tensile strength tests, hardness measurements, and dimensional inspections. Non-destructive testing methods, such as ultrasonic or X-ray inspections, may be employed to detect any internal flaws or inconsistencies in the material.

Chemical composition analysis is also crucial to verify that the titanium alloy meets the Grade 5 specifications. This involves precise measurement of the aluminum and vanadium content, as well as ensuring that impurity levels are within acceptable limits. These quality assurance measures are essential in maintaining the high standards expected of titanium fasteners in critical applications.

Conclusion

Grade 5 titanium acorn nuts have rightfully earned their place as the industry standard in high-performance fastening solutions. Their unique combination of strength, lightness, and corrosion resistance makes them indispensable in a wide range of demanding applications, from aerospace to marine environments. As industries continue to push the boundaries of performance and efficiency, the role of these advanced fasteners is likely to grow even further.

For those seeking to leverage the benefits of Grade 5 titanium acorn nuts in their projects or products, it's crucial to partner with experienced manufacturers who understand the intricacies of working with this exceptional material. Baoji Chuanglian New Metal Material Co., Ltd. stands at the forefront of titanium product manufacturing, offering expertise and quality that meet the highest industry standards. For more information or to discuss your specific titanium fastener needs, please contact us at info@cltifastener.com or djy6580@aliyun.com.