The Evolution of Lug Bolts in Motorsports

The world of motorsports has continuously been at the cutting edge of car advancement, continually pushing the boundaries of design to pick up indeed the scarcest advantage on the track. One region that has seen noteworthy progression is the humble carry jolt, which plays a vital part in securing wheels to vehicles amid high-speed races.

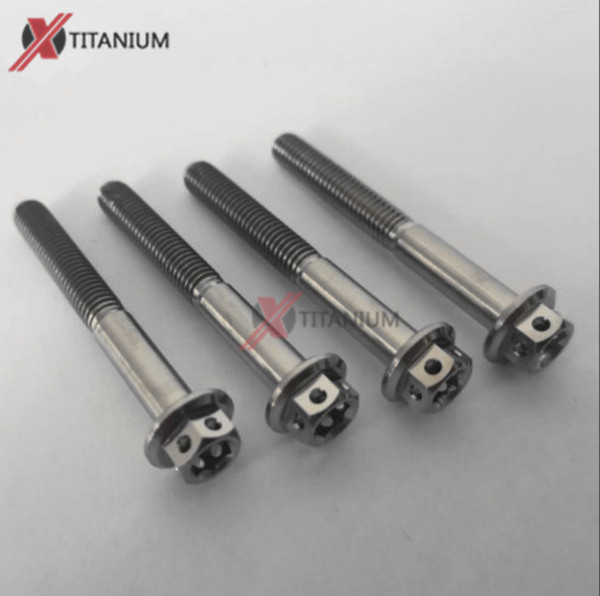

From Steel to Titanium: A Lightweight Revolution

Traditionally, steel lug bolts were the go-to choice for racing teams due to their strength and reliability. However, as the quest for speed intensified, engineers began exploring alternative materials to reduce weight without compromising safety. This search led to the adoption of titanium lug bolts, which offer a superior strength-to-weight ratio compared to their steel counterparts.

Titanium lug bolts typically weigh about 40-50% less than steel bolts of the same size. This weight reduction might seem insignificant at first glance, but when multiplied across all four wheels and considered in the context of rotational mass, the impact becomes substantial. The decreased weight contributes to reduced unsprung mass, which in turn improves suspension response, tire contact with the road, and overall vehicle dynamics.

Advantages Beyond Weight Reduction

While weight reduction is a primary benefit, titanium lug bolts offer several other advantages that make them invaluable in motorsports:

- Increased Strength: Despite being lighter, titanium lug bolts often exhibit higher tensile strength than steel bolts, ensuring secure wheel attachment even under extreme racing conditions.

- Corrosion Resistance: Titanium's natural resistance to corrosion means these bolts maintain their integrity over time, even when exposed to harsh weather conditions or corrosive brake dust.

- Heat Resistance: Titanium's high melting point allows it to maintain its strength at elevated temperatures, crucial for components near brake systems that generate significant heat during races.

- Fatigue Resistance: The material properties of titanium provide excellent resistance to fatigue, reducing the risk of bolt failure due to repeated stress cycles.

Engineering Challenges and Solutions

The adoption of titanium lug bolts in motorsports wasn't without its challenges. Engineers had to overcome several hurdles to fully realize the potential of this advanced material.

Galling and Thread Design

One of the primary issues encountered with titanium fasteners is galling, a form of adhesive wear that can cause threads to seize or become damaged. This problem is particularly acute with titanium due to its tendency to form strong bonds under pressure and friction. To address this, engineers developed specialized coatings and thread designs:

- Anti-Galling Coatings: Application of materials like molybdenum disulfide or proprietary PVD (Physical Vapor Deposition) coatings to reduce friction and prevent galling.

- Optimized Thread Profiles: Development of thread designs that minimize contact area while maintaining strength, reducing the likelihood of galling.

- Lubricants: Use of specialized lubricants compatible with titanium to further reduce friction during installation and removal.

Torque Specifications and Installation Procedures

The unique properties of titanium necessitated a reevaluation of torque specifications and installation procedures. Racing teams had to adapt their practices to ensure proper bolt tension without risking damage to the fasteners or the components they secure:

- Precise Torque Control: Implementation of highly accurate torque wrenches and monitoring systems to achieve optimal bolt tension.

- Training and Education: Rigorous training programs for pit crews to ensure proper handling and installation of titanium lug bolts.

- Regular Inspection: Development of protocols for frequent inspection and replacement of lug bolts to maintain safety and performance.

Impact on Racing Performance and Strategy

The introduction of titanium lug bolts has had far-reaching effects on racing performance and strategy, extending beyond mere weight reduction.

Enhanced Vehicle Dynamics

The reduced unsprung weight provided by titanium lug bolts contributes to improved vehicle dynamics in several ways:

- Faster Acceleration: Less rotational mass allows for quicker wheel speed changes, improving acceleration out of corners.

- Improved Braking: Reduced inertia in the wheel assembly can lead to shorter stopping distances and better brake modulation.

- Enhanced Cornering: Lighter wheels and associated components allow the suspension to react more quickly to road surface changes, potentially improving grip and stability in corners.

Pit Stop Strategy

The use of titanium lug bolts has also influenced pit stop strategies:

- Faster Wheel Changes: The lighter weight of titanium bolts can make them easier and quicker to remove and install during pit stops, potentially shaving crucial tenths of a second off pit times.

- Reduced Fatigue: Pit crew members may experience less fatigue when working with lighter components, potentially improving consistency over long races.

- Temperature Management: The heat resistance of titanium allows for quicker handling of lug bolts immediately after a car comes in from the track, reducing cooling time requirements.

Long-Term Cost Considerations

While titanium lug bolts are more expensive initially, their durability and performance benefits can offer long-term cost advantages:

- Extended Lifespan: The corrosion and fatigue resistance of titanium can lead to longer service life, reducing replacement frequency.

- Performance Gains: The cumulative effect of weight reduction and improved dynamics can contribute to better race results, potentially offsetting the higher initial cost through increased prize money or sponsorship opportunities.

- Reduced Maintenance: Less frequent replacements and inspections can lower overall maintenance costs over a racing season.

Conclusion

Titanium lug bolts have indeed proven to be a secret weapon in motorsports engineering, offering a blend of lightweight properties, strength, and durability that contributes significantly to racing performance. As materials science and building proceed to development, we can anticipate encouraging refinements and developments in this significant component of race car plan.

For teams and enthusiasts looking to explore the benefits of titanium lug bolts, consulting with specialized manufacturers is essential. Baoji Chuanglian New Metal Material Co., Ltd. offers expertise in titanium products, including high-performance fasteners for motorsports applications. For more information or inquiries about titanium lug bolts and other titanium components, please contact us at info@cltifastener.com or djy6580@aliyun.com.