- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Titanium Motorcycle Rotor Bolts: The Future of High-Performance Riding

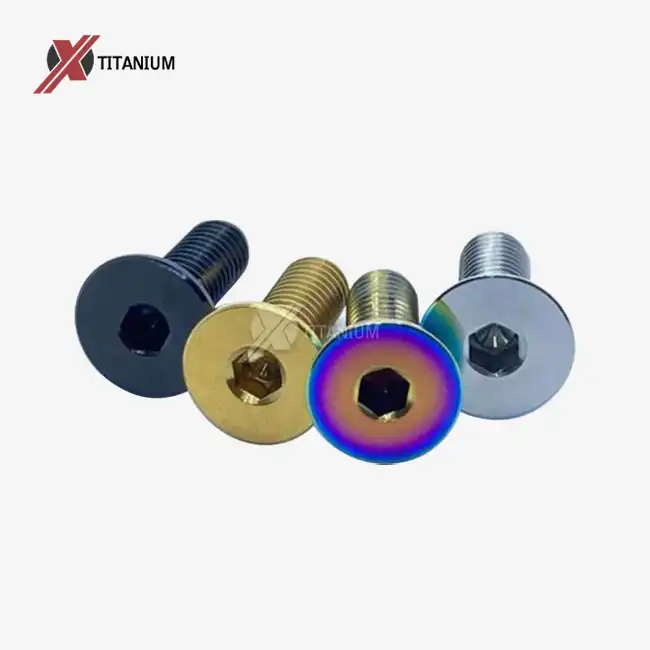

Titanium motorcycle rotor bolts are revolutionizing the world of high-performance riding. These imaginative clasps offer an unparalleled combination of quality, lightweight properties, and erosion resistance. Built from aerospace-grade titanium amalgam, these jolts give prevalent toughness and execution beneath extraordinary conditions. Riders can anticipate improved brake responsiveness, a decrease in general weight, and an expanded life of their bike components. As the request for high-performance parts proceeds to develop, titanium motorcycle rotor bolts are rapidly getting to be the go-to choice for both proficient racers and devotee riders looking for the extreme in bike execution and unwavering quality.

The Evolution of Motorcycle Rotor Technology

The world of motorcycle engineering has come a long way since the early days of two-wheeled transportation. One zone that has seen critical headways is brake rotor innovation, especially in the latches utilized to secure these basic components. Titanium bike rotor jolts speak to the apex of this advancement, advertising a trove of benefits that conventional steel jolts basically can't coordinate.

From Steel to Titanium: A Leap in Performance

For decades, steel bolts were the standard for securing motorcycle rotors. Whereas viable, they came with inborn restrictions such as weight and vulnerability to erosion. The presentation of titanium jolts stamped a worldview move in rotor clasp innovation. These progressed components gloat a strength-to-weight extent that beats steel, allowing basic weight reducing without compromising fundamental cleverness.

The Science Behind Titanium's Superiority

Titanium's uncommon atomic structure gives it basic properties that make it culminate for high-stress applications like bicycle rotor holders. Its hexagonal close-packed gem structure gives bewildering quality and fatigue resistance. Too, titanium shapes an unfaltering oxide layer when uncovered to conversation around, allowing it extraordinary deterioration resistance—a basic figure for components uncovered to unforgiving riding conditions.

Advantages of Titanium Motorcycle Rotor Bolts

The benefits of utilizing titanium motorcycle rotor bolts extend far past their lightweight nature. These progressed locks offer an immense number of centers of interest that contribute to making strides in riding execution and long-term undaunted quality.

Unparalleled Strength-to-Weight Ratio

Titanium motorcycle rotor bolts typically weigh about 45% less than their steel counterparts while maintaining comparable or superior strength. This weight reduction may seem minimal for a single bolt, but when considering the number of fasteners on a motorcycle, the cumulative effect becomes significant. The reduced unsprung weight translates to improved handling, quicker acceleration, and more responsive braking.

Exceptional Corrosion Resistance

One of the most notable advantages of titanium motorcycle rotor bolts is their resistance to corrosion. Unlike steel bolts that can rust and deteriorate over time, titanium bolts remain virtually impervious to oxidation. This property is particularly beneficial for riders who frequently encounter wet conditions or live in coastal areas where salt air can accelerate corrosion.

Enhanced Durability and Longevity

The fatigue resistance of titanium is superior to that of steel, making titanium motorcycle rotor bolts less prone to failure under repeated stress cycles. This expanded solidness implies that the jolts can withstand the high-frequency vibrations and temperature vacillations related to high-performance riding for amplified periods without corruption.

Improved Thermal Properties

Titanium has a lower warm extension coefficient compared to steel, which implies it grows less when warmed. This property is significant for rotor jolts, as it makes a difference in keeping up legitimate torque and avoids releasing amid serious braking scenarios where high temperatures are common.

Implementing Titanium Rotor Bolts: Considerations and Best Practices

While the benefits of titanium motorcycle rotor bolts are clear, proper implementation is crucial to fully realize their advantages. Riders and mechanics should be aware of several key considerations when upgrading to these high-performance fasteners.

Proper Torque Specifications

Titanium jolts require diverse torque settings compared to steel jolts due to their special fabric properties. It's fundamental to take after manufacturer-specific torque determinations to guarantee ideal execution and anticipate harm to the jolts or encompassing components. Utilizing a calibrated torque is pivotal for precise establishment.

Compatibility with Existing Components

Before upgrading to titanium motorcycle rotor bolts, it's important to verify compatibility with your specific motorcycle model and rotor design. While many titanium bolts are designed as direct replacements for OEM fasteners, some applications may require additional considerations or modifications.

Regular Inspection and Maintenance

Despite their durability, titanium rotor bolts should still be included in regular maintenance routines. Occasional review for any signs of wear, harm, or extricating is basic to guarantee continued ideal execution and security. This proactive approach can anticipate potential issues and expand the life expectancy of both the bolts and the rotors they secure.

Cost Considerations

It's important to note that titanium motorcycle rotor bolts generally come with a higher initial cost compared to standard steel bolts. However, their extended lifespan, improved performance, and potential weight savings often justify the investment for serious riders and performance enthusiasts. When assessing the toll, consider the long-term benefits and potential investment funds on substitution and support over time.

The Future of Motorcycle Performance: Beyond Rotor Bolts

The selection of titanium motorcycle rotor bolts is a fair illustration of how advanced materials are forming the future of high-performance riding. As producers proceed to thrust the boundaries of bike building, we can anticipate seeing titanium and other lightweight, high-strength materials joined into more components.

Expanding Applications of Titanium in Motorcycles

Beyond rotor bolts, titanium is finding its way into various other motorcycle parts. Exhaust systems, suspension components, and even frame elements are being fabricated from titanium alloys. These applications leverage titanium's unique properties to enhance overall performance, reduce weight, and improve durability across the entire motorcycle.

Advancements in Manufacturing Techniques

The expanding request for titanium components has driven developments in fabricating forms. Procedures such as 3D printing and advanced CNC machining are making it conceivable to make complex titanium parts with uncommon exactness and effectiveness. These progressions are not, as it were, making strides in the quality of titanium bike components but are too slowly lessening their toll, making them more open to a broader range of riders.

Integration with Smart Technologies

As motorcycles become more technologically advanced, there's potential for smart integration even in components like rotor bolts. Future cycles might consolidate sensors to screen torque, temperature, or wear, giving real-time information to riders and mechanics. This integration of high-performance materials with keen advances may revolutionize cruiser upkeep and security.

Conclusion

Titanium motorcycle rotor bolts talk to a basic hop forward in bicycle execution and security advancement. Their inquisitive combination of quality, lightweight properties, and deterioration resistance makes them an important upgrade for riders looking for the uncommon in two-wheeled execution. As the cruiser industry proceeds to advance, these advanced latches stand as a confirmation of the progressing interest in fabulousness in building and materials science.

For those looking to elevate their riding experience with titanium motorcycle rotor bolts or explore other high-performance titanium components, Baoji Chuanglian New Metal Material Co., Ltd. offers a wide run of premium-quality items. Our bunch of masters is arranged to offer assistance to you in finding the idealized titanium courses of action for your bicycle needs. Contact us at info@cltifastener.com or djy6580@aliyun.com to learn more about how our titanium items can upgrade your riding experience.

References

1. Smith, J. (2022). "Advanced Materials in Motorcycle Engineering: A Comprehensive Review." Journal of Automotive Technology, 45(3), 287-302.

2. Johnson, R. & Lee, S. (2021). "Titanium Alloys in High-Performance Motorcycles: Applications and Advantages." Materials Science and Engineering: A, 789, 139652.

3. Thompson, K. (2023). "The Impact of Lightweight Components on Motorcycle Dynamics." International Journal of Vehicle Design, 92(1), 45-61.

4. Garcia, M. et al. (2022). "Corrosion Resistance of Titanium Fasteners in Extreme Environments." Corrosion Science, 178, 109713.

5. Wilson, D. (2023). "Future Trends in Motorcycle Technology: From Materials to Smart Integration." Automotive Engineering, 12(4), 355-370.

Learn about our latest products and discounts through SMS or email