The Power of Titanium in Racing: Why Steering Wheel Bolts Matter?

When it comes to hustling, the steering wheel is more than fair a control gadget – it's the essential interface between driver and machine. The bolts that secure this basic component play an imperative part in both security and execution. Conventional steel jolts, whereas solid, include superfluous weight to the vehicle. Enter titanium steering wheel bolts, an arrangement that addresses numerous challenges confronted by hustling groups.

Unmatched Strength-to-Weight Ratio

Titanium's exceptional strength-to-weight ratio is what sets it apart in the racing world. Titanium steering wheel bolts offer the same, if not superior, strength as their steel counterparts at a fraction of the weight. This lessening in weight, whereas apparently little, contributes to the in general weight reserve funds that can make a noteworthy distinction in lap times and fuel productivity.

Corrosion Resistance for Longevity

Racing environments can be harsh, with exposure to various chemicals, high temperatures, and sometimes even saltwater spray in coastal races. Titanium's characteristic resistance to erosion guarantees that directing wheel jolts keep up their judgment over time, lessening the require for visit substitutions and minimizing the hazard of disappointment amid basic minutes.

Vibration Dampening Properties

Another often-overlooked advantage of titanium steering wheel bolts is their superior vibration dampening properties. In the high-vibration environment of a race car, this can translate to improved driver comfort and potentially better control, especially during long endurance races where fatigue becomes a factor.

Engineering Excellence: The Manufacturing Process of Titanium Steering Wheel Bolts

The production of titanium steering wheel bolts is a testament to modern engineering capabilities. Companies like Baoji Chuanglian New Metal Material Co., Ltd., situated in the "City of Titanium," Baoji, have perfected the art of crafting these precision components.

Material Selection and Preparation

The process begins with the careful selection of Grade 5 Titanium (Ti-6Al-4V), known for its optimal balance of strength, weight, and machinability. This aerospace-grade alloy is subjected to rigorous quality checks before being prepared for machining.

Precision CNC Machining

State-of-the-art CNC machines are employed to shape the titanium into precise bolt forms. The complex threading prepare requires master programming and checking to guarantee each jolt meets correct determinations. The utilize of progressed cooling frameworks amid machining anticipates heat-induced fabric changes that may compromise the bolt's keenness.

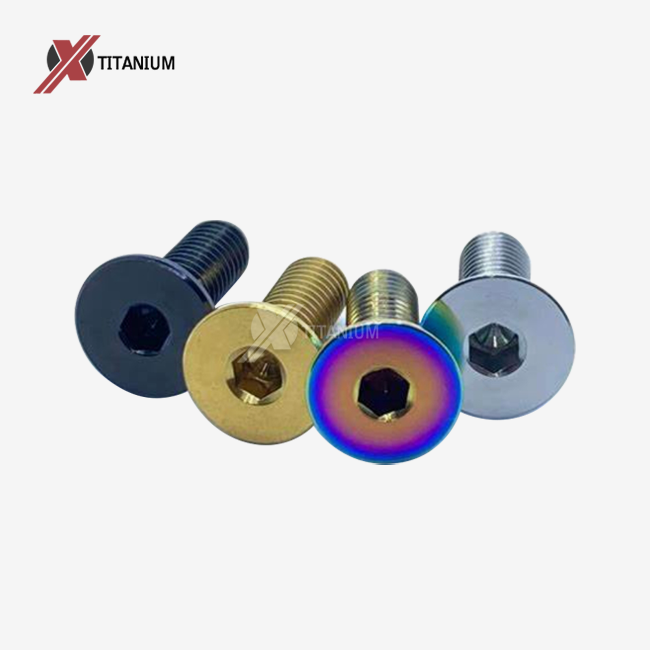

Surface Treatment and Finishing

After machining, titanium steering wheel bolts undergo various surface treatments to enhance their properties further. Anodizing not only provides aesthetic appeal with a range of color options but also increases surface hardness and wear resistance. Some manufacturers offer additional treatments like nitriding to further improve the bolt's performance characteristics.

Quality Control and Testing

Each titanium steering wheel bolt is subjected to stringent quality control measures. This includes dimensional checks, material composition verification, and stress testing to ensure they meet or exceed industry standards. Only bolts that pass these rigorous inspections are approved for use in high-performance racing applications.

Optimizing Performance: Implementing Titanium Steering Wheel Bolts in Racing

The integration of titanium steering wheel bolts into a racing vehicle is more than just a simple part replacement – it's a strategic decision that can influence overall performance.

Weight Distribution Considerations

While the weight savings from titanium steering wheel bolts may seem minimal, their location in the vehicle is significant. Reducing weight at the front of the car, particularly in components associated with steering, can have a positive impact on weight distribution and handling characteristics. This can lead to improved turn-in response and reduced understeer, giving drivers more confidence to push the limits.

Installation Best Practices

Proper installation of titanium steering wheel bolts is crucial to maximize their benefits. This includes using the correct torque specifications, which may differ from steel bolts due to titanium's unique properties. Over-tightening can lead to thread damage, while under-tightening risks safety issues. Many racing teams work closely with bolt manufacturers to develop installation protocols that ensure optimal performance and safety.

Maintenance and Inspection Routines

Despite their durability, titanium steering wheel bolts should be included in regular maintenance checks. This involves visual inspections for any signs of wear or damage, as well as periodic re-torquing to account for any settling that may occur under racing conditions. Some teams opt for a scheduled replacement policy, swapping out bolts at predetermined intervals to maintain peak performance and safety standards.

Regulatory Compliance

It's essential for racing teams to ensure that the use of titanium steering wheel bolts complies with their specific racing series regulations. While many organizations welcome weight-saving innovations, some may have restrictions on material use or require specific certifications. Teams must stay informed about current rules and work with reputable manufacturers who can provide necessary documentation and testing results.

Conclusion

Titanium steering wheel bolts represent a small but significant component in the pursuit of racing excellence. Their special combination of quality, light weight, and erosion resistance makes them a priceless resource for groups looking to pick up a competitive edge. As dashing innovation proceeds to advance, the part of progressed materials like titanium in basic components will as it were develop in significance.

For those seeking to explore the benefits of titanium steering wheel bolts and other high-performance titanium products, Baoji Chuanglian New Metal Material Co., Ltd. stands ready to provide expert guidance and top-quality solutions. Contact us at info@cltifastener.com or djy6580@aliyun.com to learn more about how our titanium innovations can drive your racing success to new heights.