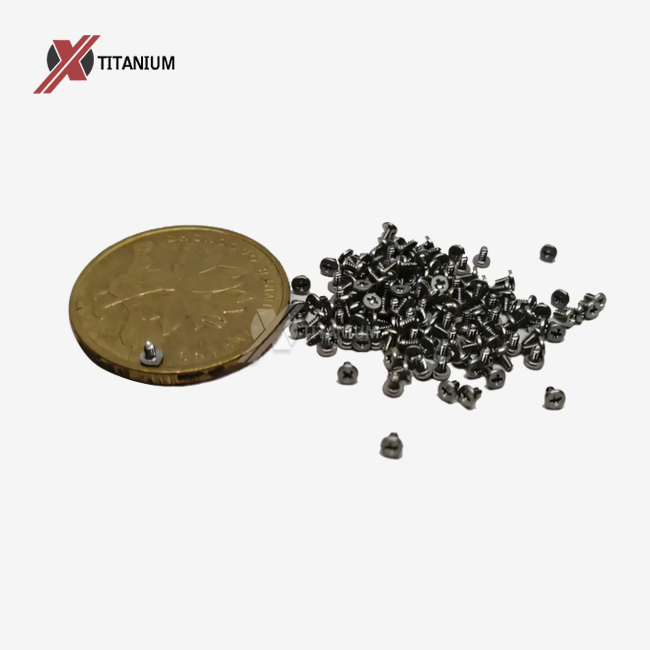

Switching to titanium fasteners is a big change for high-performance applications in the aerospace, medical, and industrial fields. These high-quality parts have strength-to-weight ratios that are better than any other material, as well as corrosion resistance and biocompatibility that other materials can't match. When accuracy is most important, titanium micro screws are more reliable than what the industry expects. They are necessary for any use that needs both strength and accuracy, from surgical implants to aerospace assembly, because of their particular features. Investing in titanium technology immediately leads to better performance, lower maintenance costs, and longer component life across a wide range of industrial uses.

Superior Material Properties and Performance Characteristics

Titanium alloys have mechanical characteristics that are quite different from those of other fastening materials. Grade 5 titanium (Ti-6Al-4V) has a tensile strength of 950 MPa and a density of just 4.43 g/cm³. This amazing strength-to-weight ratio is especially important in aeronautical applications where every gram affects fuel economy and payload capacity.

The Young's modulus of the material, which is 114 GPa, gives it the right amount of stiffness without making it brittle. Titanium micro screws maintain the same size even when the temperature changes a lot, from -200°C to 400°C. This thermal stability makes sure that the device works the same way in all kinds of tough conditions.

The fact that titanium can create a protective oxide layer makes it resistant to corrosion. This passive film repairs itself when it is damaged, which gives it self-healing capabilities. This feature is quite useful for marine applications since titanium fasteners don't corrode in seawater.

Biocompatibility makes titanium the best choice for medical uses. The substance works well with human tissue and doesn't cause any problems. Orthodontic titanium screws and micro screw implants use this feature to make sure that the implants last a long time.

Enhanced Durability and Longevity Benefits

Titanium lasts longer than steel or aluminum since it doesn't get tired as easily. Tests in a lab show that titanium alloy micro screws can handle more than 10 million stress cycles without breaking. This capacity to last longer cuts down on how often you need to replace things and how much it costs to keep them up.

Because the material is stable when it is loaded and unloaded repeatedly, it is great for dynamic uses. Aerospace parts that are always vibrating and going through heat cycling depend on titanium's steady performance. Engine parts that use titanium bone screws stay strong even after long years of use.

Because titanium fasteners are chemically inert, they won't be harmed by strong chemicals. This tolerance to acids, bases, and organic solvents is good for petrochemical processing equipment. The substance stays strong even when it is in contact with chlorine, which quickly breaks down other metals.

Surface treatments make things even more durable. Anodizing produces regulated oxide coatings that make things more resistant to wear and let you color code things. Nitriding makes the surface harder while keeping the core flexible. These treatments make parts last longer than the basic material can.

Weight Reduction and Efficiency Improvements

Using titanium, such with titanium micro screws, may save 40–60% of the weight compared to steel fasteners of the same strength. This reduction has a direct effect on how much fuel is used in aeronautical applications and makes automobile systems more power-efficient. Racing applications gain a lot from less unsprung weight, which makes handling better.

Lower density lets designers change the shapes of parts without making them weaker. Micro fixation screws may make thinner profiles while yet keeping things in place. This capacity to make things smaller is very important in electronics and medical devices where space is quite limited.

Less rotational inertia makes moving parts respond better to changes in speed. Turbine parts that use titanium screw fasteners speed up and work better. The total weight loss from using many fasteners leads to significant improvements in performance.

Transportation businesses save a lot of money on operations by getting better gas mileage. Commercial airplane operators say that using titanium fasteners saves them money in real terms. Marine boats benefit from less weight and better speed.

Chuanglian's Titanium Micro Screws vs Competitor Solutions

We have more than ten years of experience working with titanium in production. We take use of the area's strengths and our profound understanding of materials in Baoji City, which is renowned as the "City of Titanium." Our precise CNC machining makes sure that the dimensions of each manufacturing run are always correct.

Quality control systems go above and beyond industry norms by using thorough testing methods. Each batch is carefully checked, from making sure the raw materials are correct to making sure the finished product is correct. Every shipment comes with traceability paperwork that shows the full history of the materials used in important applications.

Our goods are different from regular catalog items since you may customize them. We can meet precise grade requirements, surface treatments, and size criteria. Our engineering team works with clients to make sure that designs are as good as they can be for their intended uses.

Compliance with certification includes AS9100, ISO9001, and any medical device standards that apply. These accreditations show that we are dedicated to following the rules and providing the best quality possible. International clients trust our approved procedures for important applications.

Technical support goes beyond just delivering the product; it also includes help with application engineering. Our metallurgists help you choose the right materials and suggest ways to process them. This knowledge makes sure that things work best in tough situations.

Optimal Application Guidelines and Usage Recommendations

Proper installation techniques maximize the performance of titanium micro screws. Torque specifications must account for titanium's unique properties to prevent galling or thread damage. Anti-seize compounds designed for titanium applications ensure smooth assembly and future serviceability.

For the best use of strength, the thread engagement ratio should stay at 1.5 times the diameter of the fastener. Micro screws for dental usage need to be able to regulate the depth very accurately so that they don't hurt the tissue and yet hold things in place. The rules for pre-drilling depend on the kind of substrate and the needs of the application.

Preparing the surface has a big effect on how well it works over time. Surfaces that are clean and free of clutter make sure that sitting and tension are evenly spread out. Sterile handling practices that keep the screws from becoming dirty during installation are good for titanium dental screws.

When choosing a material grade, environmental factors are important. For the best resistance to corrosion, marine applications choose commercially pure titanium. Alpha-beta alloys that keep their strength at high temperatures are needed for high-temperature uses.

Supplier certification and material traceability should be important parts of procurement plans. Building ties with qualified manufacturers makes sure that the quality is always good and the delivery dates are always accurate. Because they are used in such important ways, micro orthopedic screws need to meet very high quality criteria.

Critical Implementation Considerations

When combining titanium with other metals, it's important to carefully consider how well they will work together. Galvanic corrosion may happen when titanium touches materials that are less noble in electrolytic conditions. Choosing the right materials or using isolation methods stops deterioration.

Machining settings must take into account how titanium hardens when it is worked. To keep the tools from wearing out and the dimensions accurate, the cutting speeds and feeds need to be optimized. Our knowledge of CNC programming lets us make things quickly while yet meeting quality requirements.

Procedures for storing and managing materials keep them safe all the way through the supply chain. Titanium self-tapping screws need to be protected from dirt and other things that might make them less biocompatible or more prone to corrosion. Proper packing keeps things clean until they are installed.

When thinking about costs, you should think about more than just the original purchase price. You should also think about the item's lifespan worth. Higher material expenses are made up for by lower maintenance costs, longer service life, and better performance. Calculations of the total cost of ownership usually show that titanium is better for tough jobs.

Different industries and uses have different rules for compliance. For medical uses, the FDA must approve the product and it must pass biocompatibility tests. In aerospace, materials must be certified and lots must be traceable. Knowing what the rules are is important for a successful execution.

Conclusion

Switching to titanium screws is a smart move that will pay off in better performance and long-term value. These high-tech fasteners have the best strength-to-weight ratios, corrosion resistance, and biocompatibility, which are all important for crucial applications. Titanium technology offers solutions that regular materials can't match, from tiny screw implantation in medical procedures to aircraft systems that need to be completely reliable. The initial expense of high-quality titanium fasteners pays off in the long run by lowering maintenance costs, extending the life of the system, and improving its performance. As industries move toward increasingly difficult tasks, titanium micro screws will still be the best option for engineers who won't settle for less quality and performance.

FAQ

Q1: What makes titanium micro screws superior to stainless steel alternatives?

A: Titanium micro screws are stronger than other types of screws, are completely biocompatible, and don't corrode easily. Stainless steel may rust in certain places, whereas titanium stays chemically stable forever. The weight loss saves 40% to 60% compared to steel fasteners of the same strength.

Q2: How do I determine the correct grade of titanium for my application?

A: The grade you choose depends on the exact performance needs. For chemical uses, commercially pure titanium (Grades 1-4) is the best choice since it is the most resistant to corrosion. For structural uses, Grade 5 (Ti-6Al-4V) has the best strength-to-weight ratio. Based on your needs, our technical staff may provide you advice that is tailored to your application.

Q3: What surface treatments are available for titanium micro screws?

A: Treatments that are available include natural finish, anodizing to add color and make the surface more resistant to rust, and nitriding to make the surface harder. We have finishes in a variety of hues, such as natural titanium, gold, blue, green, purple, black, and rainbow. Each treatment has a distinct purpose, either utilitarian or aesthetic.

Partner with Chuanglian for Premium Titanium Micro Screws

Chuanglian makes sure that every product is of the highest quality by using precise production and strict quality control. We make titanium micro screws for clients in the aerospace, medical, and industrial fields all around the globe. We satisfy a wide variety of application needs by offering sizes from M1 to M3 and bespoke specifications. Take advantage of Chuanglian's quality materials, experienced technical assistance, and dependable delivery performance. Contact us at info@cltifastener.com or djy6580@aliyun.com to discuss your titanium fastener requirements.

References

1. Boyer, R.R. "An Overview on the Use of Titanium in the Aerospace Industry." Materials Science and Engineering: A, vol. 213, 1996, pp. 103-114.

2. Geetha, M., et al. "Ti Based Biomaterials, the Ultimate Choice for Orthopaedic Implants – A Review." Progress in Materials Science, vol. 54, no. 3, 2009, pp. 397-425.

3. Lutjering, G., and Williams, J.C. "Titanium: Engineering Materials and Processes." 2nd edition, Springer-Verlag, 2007.

4. Rack, H.J., and Qazi, J.I. "Titanium Alloys for Biomedical Applications." Materials Science and Engineering: C, vol. 26, no. 8, 2006, pp. 1269-1277.

5. Peters, M., et al. "Titanium Alloys for Aerospace Applications." Advanced Engineering Materials, vol. 5, no. 6, 2003, pp. 419-427.

6. Niinomi, M. "Mechanical Biocompatibilities of Titanium Alloys for Biomedical Applications." Journal of the Mechanical Behavior of Biomedical Materials, vol. 1, no. 1, 2008, pp. 30-42.